Mechanical ventilation in tunnel- and cross-ventilated barns can be well worth the resources it requires to maintain a controlled, comfortable environment, but there are a few questions to be addressed:

- How many fans do you really need?

- Will the electrical bill go through the roof?

- And how much precious water will a sprinkler or evaporative cooling system use?

How many fans do I need?

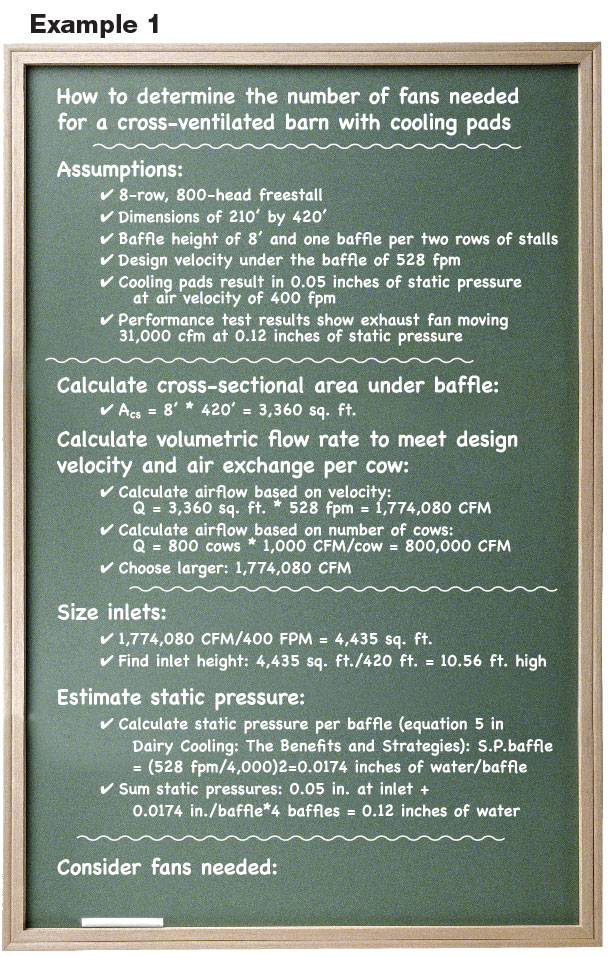

The total ventilation capacity should meet two criteria: air exchange and air velocity at cow level. Summer air exchange rates should be a minimum of 1,000 CFM per cow. However, this value is usually significantly exceeded to attain the desired air velocity of 400 to 600 fpm at cow level. To determine the number of fans needed to provide the desired flow rate (see Example 1), use the following steps:

1. Calculate cross-sectional area under baffle.

Areacs [square feet] = heightbaffle [feet] x lengthbaffle [feet]

2. Calculate airflow (Q) necessary to achieve design velocity.

Q [CFM] = Velocity [fpm] x Areacs [square feet]

3. Calculate airflow necessary to achieve 1,000 CFM per cow.

Q [CFM] = 1,000 [CFM/cow] x number of cows

4. Choose the larger of two airflow rates.

5. Divide larger flow rate by the airflow per fan at the barn’s estimated static pressure.

Number of exhaust fans = Q [CFM] / airflow per fan [CFM / fan]

Click on the image above to view it in more detail.

What fans do I need?

In general, larger fans operate more efficiently than smaller fans. However, this is only true to a point. Independently tested 72-inch fans show dramatically reduced performance at higher static pressures.

Since fan capacity decreases as static pressure increases, fans should be selected based on their performance at the static pressure they will be operating. Static pressure often ranges from 0.1 inch of water for average tunnel-ventilated barns up to 0.25 inch in large barns with baffles and evaporative cooling pads. Evaporative pads alone can add between 0.05 to 0.1 inch of static pressure, depending on the velocity of air passing through them.

Estimating electricity and water use

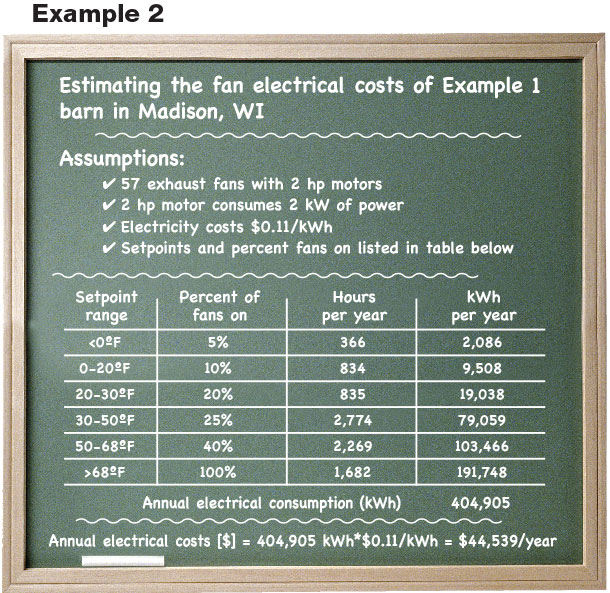

The quantity of electricity used by the fans can be estimated by multiplying the power consumption of the fans’ motors by the typical number of hours per year the fans operate (see Example 2). For the examples below, the number of hours in each set-point range were counted from the National Renewable Energy Laboratory’s Typical Meteorological Year Database.

Click on the image above to view it in more detail.

When estimating electrical costs, note that motor horsepower is given in mechanical output and that the electrical input is always greater. A typical 1-horsepower motor requires around 1 kilowatt of electrical power. Exhaust fans consume slightly more at higher static pressure and less at lower pressures.

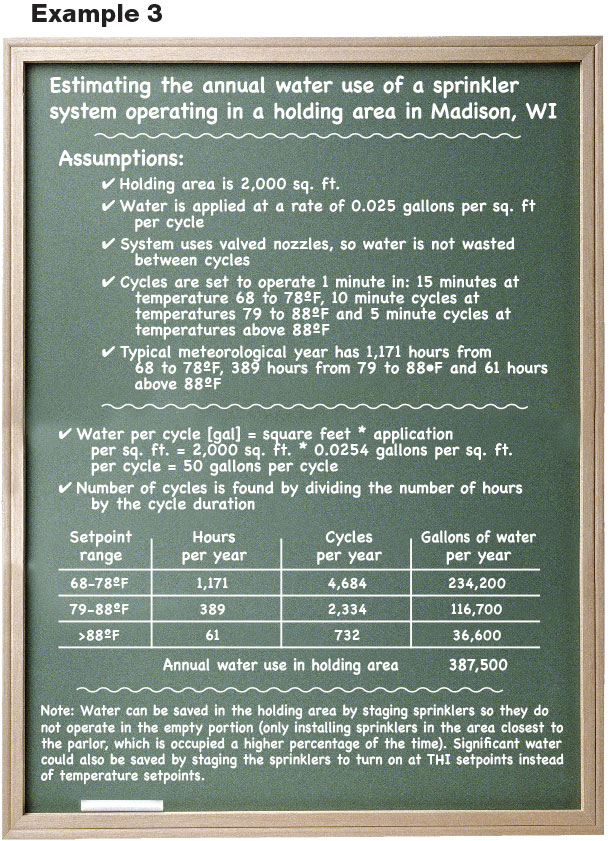

The water used by a sprinkler system can also be estimated by multiplying the system’s set points by the typical number of hours per year within each set-point range (see Example 3).

Click on the image above to view it in more detail.

Water use from evaporative cooling pads is more difficult to estimate because it is dependent on the ambient temperature and humidity, evaporation efficiency of the cooling pad and ventilation rate of the barn. One study in western Iowa measured water use by evaporative cooling pads at an average of 13 gallons per stall per day and a maximum of 22.7 gallons per stall per day.