This guide is a climate-specific extension of the summary article “Dairy Cooling: The Benefits and Strategies,” which describes heat stress, its costs and consequences, and several strategies for its mitigation.

Herein, we focus on the special challenges faced by dairy producers seeking to prevent heat stress in regions with hot and humid summers and warm winters. We discuss the various facility design options and the pros, cons and costs of the ventilation and cooling systems most commonly used in freestall barns located in these regions.

Climate

The American Southeast (as well as parts of South America, Africa, Europe and Asia) is dominated by a climate classified as “humid subtropical,” which is characterized by summer seasons that are both hot and humid. The high temperatures reduce the amount of heat that can be dissipated by convection, and the high humidities limit evaporation. As a consequence, dairy cows raised in these climates are, on average, more greatly affected by heat stress than cows raised in humid but cooler continental climates, not to mention cooler and drier climates.

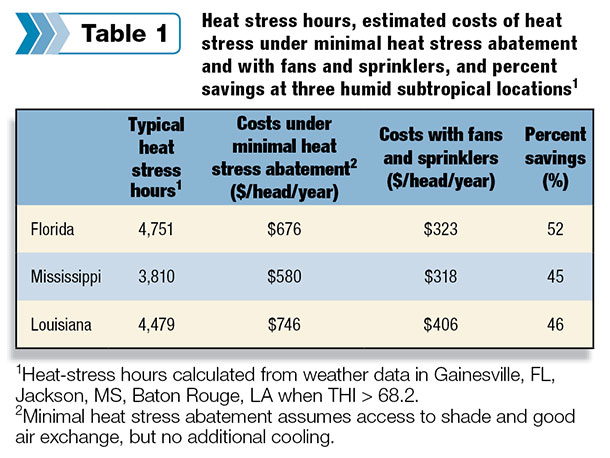

While no system is likely to completely eliminate the effects of heat stress when both temperature and humidity levels are high, increasing air velocity over the cow and providing some form of evaporative cooling can reduce the costs associated with heat stress by more than 45 percent (including the annualized capital costs and operating costs of the cooling systems). Table 1 presents the typical number of heat stress hours and the estimated costs of heat stress in three humid subtropical states under minimal heat stress abatement and with fans and sprinklers.

Common facilities and ventilation types

To better manage manure and provide improved cow comfort, many dairies in the American Southeast have adopted freestall housing. However, because winters are generally relatively warm, shade structures located in the pasture are also a viable option that is still relatively common for dry cows. For cows managed in this unconfined way, cooling ponds provide an additional option for relieving heat stress.

Freestall barns in this climate are often naturally ventilated during winter and provide additional air velocity during hot weather with circulation fans or by converting to mechanical-tunnel ventilation. Barns using circulation fans for hot weather air velocity are typically more open than naturally ventilated barns in cooler climates, without end walls or sidewalls and with wider ridge openings. Barns that are converted to tunnel ventilation during hot weather require curtain sidewalls to enclose the barn. Alternatively, some tunnel-ventilated barns have permanent sidewalls and are mechanically ventilated year-round. A number of large dairies in the Midwest have built low-profile, cross-ventilated (LPCV) barns in the last decade. However, LPCV barns are not common in hot and humid climates.

To protect the cows from the effects of thermal radiation, the roof of any shade structure can be painted white and insulation can be installed on its underside. White paint fades over time, and insulation needs a hard surface underneath to prevent birds and rodents from nesting.

Choosing a ventilation and cooling system

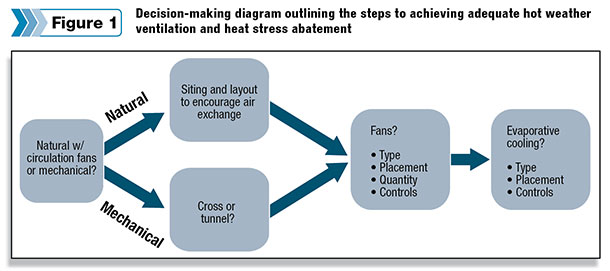

Because the ideal barn shape differs between naturally ventilated barns with circulation fans and mechanically ventilated barns, deciding which of these systems to implement is the first step. Additional equipment and design specifics can then be selected to provide evaporative cooling and high air velocity. This process is outlined in Figure 1 below.

Natural (with supplemental cooling) or mechanical

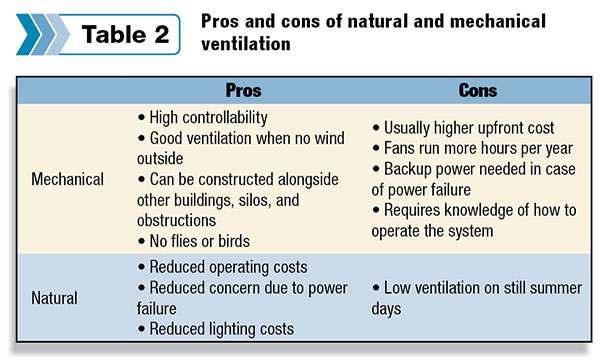

Both open-sided, naturally ventilated barns with supplemental cooling and totally enclosed, mechanically ventilated barns can effectively reduce heat stress in hot and humid climates, if they provide good air velocity at cow level and some form of evaporative cooling. For smaller barns, circulation fans (to supplement natural ventilation) are almost always less expensive than the exhaust fans needed for mechanical ventilation. However, the cost per cow of mechanical ventilation decreases as the tunnel-ventilated barn becomes longer (and as the cross-ventilated barn gets wider) until it approaches a “critical length,” at which point the cost of the exhaust fans used for mechanical ventilation becomes less than the cost of installing circulation fans throughout the entire barn. This critical length has been estimated to be about 500 feet for a tunnel-ventilated barn. An additional cost of using mechanical ventilation is from curtain or permanent sidewalls needed to enclose the structure. The pros and cons of natural and mechanical ventilation in humid subtropical climates are summarized in Table 2.

Naturally ventilated barns

Basic siting and layout

Natural ventilation is effective at sites with consistent wind and away from other buildings and obstructions. Orienting the open sidewalls perpendicular to summertime prevailing winds provides the best ventilation, and an east-west orientation provides the best shade. The direction and intensity of prevailing winds can be found by consulting “wind rose” diagrams, such as those found in this index. See Table 3 in the companion summary article, “Dairy Cooling: The Benefits and Strategies” (PDF, 478KB), to determine the height of sidewall openings, which are generally between 10 and 16 feet high. If obstructions are present, larger sidewall openings can compensate to some extent. In Florida, the recommended ridge opening is 1 foot plus 2 inches per 10 feet of building width, which is wider than is typical in the Midwest or Northeast.

Supplemental cooling for naturally ventilated barns

In hot and humid climates, shade and natural ventilation are not sufficient for reducing heat stress. Circulation fans and evaporative cooling should be provided in open-sided barns for effective heat stress relief.

Circulation fans

Type

Other than cost, several factors that should influence the selection of circulation fans are their throw, efficiency, reliability and ease of maintenance.

Location and quantity

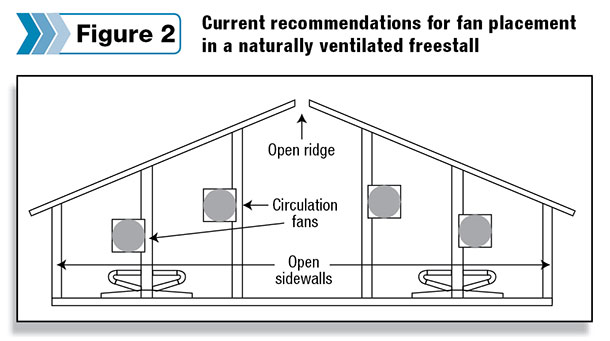

The current recommendation for circulation fan placement is to locate one row of fans over the stalls and one row over the feedline as shown in Figure 2. This is based on a Kansas State study that compared the performance of cows housed in pens cooled by fan and sprinkler systems laid out in various ways. The study found that fans placed over both the feedline and stalls significantly improved milk production, but that two rows of fans installed over head-to-head stalls did not provide additional benefits.

However, if the fans placed above a row of head-to-head stalls are staggered – that is to say, if the first fan is placed to one side above the first stall and the next fan is placed above the alternate side of the next stall, and so on, then a more even airflow may be achieved.

Usually, circulation fans are placed 10 fan diameters apart, although some producers have opted to space fans more closely together to produce a greater air velocity. Fans should be placed a minimum of 8 feet above the barn floor and tilted down at a 25- to 35-degree angle. The closer and higher the fans are mounted, the steeper the pitch. One should be able to feel the air at their feet when standing at the next fan.

See the companion summary article for information on fan placement in the holding area.

Priority for circulation fans

When available funds will not cover the costs of installing circulation fans in all desired locations, the funds should be applied according to the following priority:

- Holding pens

- Close-up (dry cow) pens

- Maternity and sick pens

- Fresh-cow pens

- High-producer pens

- Low-producer pens

There is increasing evidence that dry cows should be cooled in hot and humid climates. In a study conducted at the University of Florida, a group of cows subjected to heat stress during their dry period produced an average of 11 pounds per cow per day less during the subsequent lactation than those that received cooling. Another study performed at the University of Florida found the average birth weight of calves born to heat stressed mothers was 80.5 pounds, as compared with 93.7 pounds for those from mothers that had received cooling.

Controls for circulation fans

The most recent guidelines recommend turning circulation fans on when the temperature exceeds 68°F. However, because it is the combination of temperature and humidity that causes heat stress, the total number of hours the fans must be on per year can be reduced by including a humidity sensor and setting the fans to turn on at a temperature humidity index (THI) of 68. Variable frequency drives (VFDs) also have the potential to save additional energy, but more research must be done to determine guidelines for how VFDs on circulation fans should be controlled as temperatures increase.

Evaporative cooling

A combination of evaporative cooling and circulation fans is more effective at reducing heat stress and will provide higher economic returns than will using fans alone. In fact, when the air temperature is higher than the cow’s body temperature and the cow’s skin is dry, fans alone will transfer heat to the cow.

Both low-pressure sprinklers and high-pressure misters mounted on fans can be effective if controlled correctly. However, high-pressure misters require an additional pump, are more prone to clogging and need additional control. For these reasons, low-pressure sprinklers are more common.

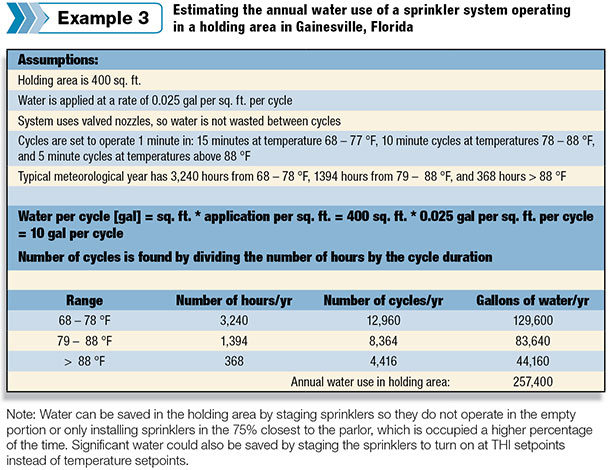

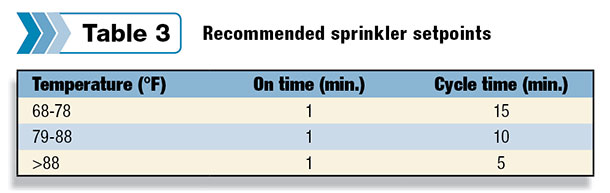

Low-pressure sprinklers should be installed in the holding area and above the feedline, but should not be installed above the stalls as constantly wet stalls can lead to a number of health issues. Install a half-circle (180-degree or less) nozzle every 6 to 8 feet along the feedline, with each delivering 0.33 gallons per cow per cycle. And 360-degree sprinklers should apply around 0.025 gallons per square foot per cycle in the holding area. Use pressure-controlled nozzles to limit system drain-down (waste) and increase the system’s responsiveness. Sprinklers should be operated in a similar manner to Table 3, although setpoints often also depend on available water and lagoon space.

Mechanically ventilated barns

Tunnel or cross?

Cross ventilation has become the preferred system in newly constructed barns housing large herds in the Midwest because it seems to provide better air velocity at cow level than tunnel-ventilated barns. Baffles are more effective in cross-ventilated barns than in tunnel-ventilated barns because they are placed above the freestall rows (as opposed to perpendicular to the rows), and thus can more effectively direct air to cow level. Cross ventilation is also advantageous because (unlike tunnel-ventilated barns) most of the cows in a cross-ventilated barn will be oriented parallel to the airflow, and thus the upstream cows block less air from reaching the downstream cows than if the cows are oriented perpendicular to the airflow.

Despite those benefits, cross ventilation is not common in hot and humid climates. Tunnel-ventilated barns have the advantage of being convertible to natural ventilation in the summer. In addition, because naturally ventilated barns are usually six rows or less (and therefore significantly longer than they are wide), it requires more fans to retrofit a naturally ventilated barn for cross ventilation than tunnel. Typically, cross-ventilated barns have a minimum of eight rows.

Evaporative cooling in mechanically ventilated barns

Mechanical ventilation is compatible with low-pressure sprinklers, high-pressure misters and evaporative cooling pads. While evaporative cooling is less effective than in arid climates, it can still provide a significant cooling effect during the hottest hours of the day (when the relative humidity [RH] is lowest). For example, at 90°F and 60 percent RH (typical summer conditions in Florida), a cooling pad or misting system operating at 75 percent evaporation efficiency produces a 8.6°F temperature reduction, which is equivalent to a reduction in THI of three units. Cooling pads cause an increase in static pressure, while misting requires more careful control because the flow rate must be adjusted to suit changing conditions. Some mechanically ventilated facilities in humid subtropical climates now rely on both evaporative cooling pads or high-pressure misters to cool the air and low-pressure sprinklers to further cool the cows at the feedline.

Baffles

Baffles provide benefits in cross-ventilated barns when oriented directly over a row of head-to-head stalls. By reducing a barn’s cross-sectional area, baffles increase the velocity of the air passing beneath them. As a result, the number of fans needed to produce a given velocity can be reduced. However, because the air velocity is redistributed between the baffles, it cannot be said with certainty that they are worthwhile in tunnel-ventilated barns (where they only provide higher velocity air to the few stalls that they directly overhang). Some owners of tunnel-ventilated barns have opted to install (instead of baffles) full ceilings at a lower level. This measure, although more expensive, increases air velocity throughout the entire barn as opposed to only beneath the baffles. It should be noted that baffles installed above the alleys should be placed high enough (12 to 13 feet) so that equipment can pass beneath, but they can be placed at a lower height (6 to 10 feet) above the stalls.

Fans for mechanical ventilation

Type

Mechanically ventilated barns are most commonly ventilated under negative pressure using exhaust fans. Positive-pressure fans are used in barns that have significant infiltration, as well as in the milking parlor. In general, larger fans operate more efficiently than smaller fans. However, this is only true to a point. Independently tested 72-inch fans show dramatically reduced performance at higher static pressures. Since fan capacity decreases as static pressure increases, fans should be chosen based on how they operate at the barn’s estimated static pressure (see the companion summary article for more information on estimating the static pressure of a specific barn).

Quantity

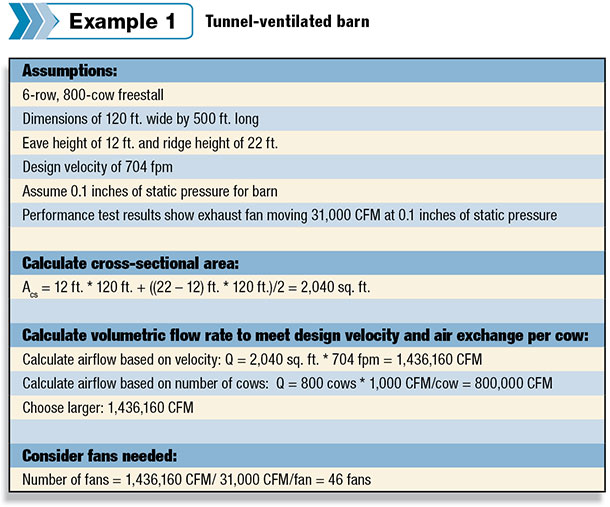

The total ventilation capacity chosen should meet two criteria: air exchange and air velocity at cow level. Summer air exchange rates should at a minimum be 1,000 cubic feet per minute (CFM) per cow. However, this value is usually significantly exceeded in order to attain the desired air velocity of 433 to 704 feet per minute (fpm) at cow level. To achieve these velocities at cow level in tunnel-ventilated barns, barns are sometimes designed with average air velocities of 704 to 880 fpm. To determine the number of fans needed to provide the desired flow rate (also see Example 1 [PDF, 112KB] in the appendix), use the following steps:

- Calculate cross-sectional area under baffle.

- Areacs [square feet] = heightbaffle [feet] x lengthbaffle [feet]

- Calculate airflow (Q) necessary to achieve design velocity.

- Q [CFM] = velocity [fpm] x areacs [square feet]

- Calculate airflow necessary to achieve 1,000 CFM per cow.

- Q [CFM] = 1,000 [CFM/cow] x number of cows

- Choose the larger of two airflow rates.

- Divide larger flow rate by the airflow per fan at the barn’s estimated static pressure.

- Number of exhaust fans = Q [CFM] / airflow per fan [CFM/fan]

Controls

Mechanical ventilation systems are staged so that some fans will always be on to provide the minimum ventilation rate, and as the temperature increases, additional fans will begin to run until all the fans are on at a temperature of 71 to 74°F. Many tunnel-ventilated barns are converted to natural ventilation during cooler weather. But if they are not, some ventilation fans must operate at all times. While a minimum ventilation rate of 50 CFM per cow is recommended in colder climates, the mild weather ventilation rate of 170 CFM per cow may be more suitable for subtropical winters. Exhaust fans equipped with VFDs can be purchased, but the airflow through the barn can also be adjusted by simply turning off some fans. VFD fans tend to be more expensive than single-speed fans, but also have the potential to operate more efficiently when only a portion of the total fan capacity is needed.

Inlets

A system’s air inlets determine the points at which air is introduced to the barn and how that air is distributed. Generally, the inlet is located on the side of the barn opposite the exhaust fans. To function properly, a mechanical ventilation system must have properly sized inlets. Smaller inlets result in higher static pressure. Airflow through evaporative pads should be limited to 300 to 400 CFM per square foot to limit static pressure, but the airflow can be as high as 600 to 800 CFM per square foot if no pads are used.

Estimating resource use

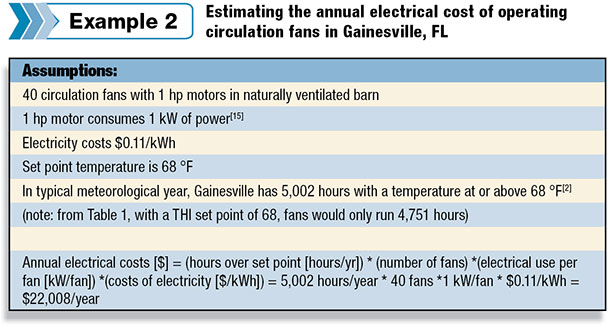

The amount of electricity used by the fans can be estimated by multiplying the power consumption of the fans’ motors by the typical number of hours per year the fans operate (see Example 2 [PDF, 117KB] in the appendix). When estimating electrical costs, note that motor horsepower is given in mechanical output and that the electrical input is always greater. A typical 1 horsepower motor requires around 1 kW of electrical power.

The water used by a sprinkler system can be estimated in a similar manner. Simply multiply the system’s setpoints by the typical number of hours per year within each set point range (see Example 3 [PDF, 113KB] in the appendix).

Conclusions

Implementing fans and some form of evaporative cooling has been shown to provide clear economic benefits in humid subtropical climates. However, determining the practices that will optimize the combination of air velocity and evaporative cooling in terms of milk production, animal health and resource efficiency will require further study. Although there are gaps in the current body of research, the guidelines contained herein should help to reduce the negative effects of heat stress in humid subtropical climates.

Acknowledgements

We would like to thank Schaefer Ventilation Equipment of Sauk Rapids, Minnesota, for their financial and technical assistance with this project. We want to especially thank Neil Crocker, Jim Evans, James Kleinke and Pete Lyle. This material is also based upon work supported by the National Science Foundation Graduate Research Fellowship Program under grant No. DGE-1256259. PD

Ian Atkins is a Ph.D. student and Christopher Choi is a professor; both are with the University of Wisconsin – Madison Department of Biological Systems Engineering.

Ray Bucklin is a professor with the University of Florida Department of Agricultural and Biological Engineering.

References omitted but are available upon request. Click here to email an editor.

PHOTO: Photo provided by Schaefer Ventilation.