Editor’s note: This is the second article in a two-part series. The first article appeared in the May 7, 2014 issue of Progressive Dairyman. Now that you have established a “master notebook system” for your milking parlor as I suggested earlier this year, let’s identify key design and maintenance issues you should track. Remember, the goal for your parlor should be to consistently, quickly, comfortably and completely milk every cow.

And none of your cows should be asked to spend more than three hours per 24-hour day out of their pens or lots for the milking activity. If this rule is violated, you will steal lying time away from them, which can lead to decreased production and increased lameness issues.

Unit alignment

To achieve the above goals, the pathway of milk must be perfect. Perfect means that from the teat end to the milk line, milk should flow “downhill.” Gravity is an important part of milking system design. It requires roughly a half-inch Hg of vacuum to lift milk 1 foot.

When milk is lifted, a slug is formed. The vacuum level behind the slug drops until it clears. This is why you cannot get steady claw vacuums in high-milk line systems.

Interestingly, top-unloading claws are designed to create mini-slugs on purpose, but due to precise engineering a predictable slug is created, thus producing a small, predictable vacuum fluctuation. Some milk meters require slugs entering them to be accurate, so milk hoses connect to them in an upward direction. This also adds to claw vacuum fluctuations.

The consequences of excessive claw vacuum fluctuations can include:

1. Discomfort to the cow

2. Increased reverse pressure gradients in the short milk tube leading to more milk moving from the claw and striking the teat end

3. Vacuum spikes increasing liner overpressures (liner pinch on the teat ends)

4. The cow being exposed to high vacuum levels during fluctuation spikes, preventing an opportunity to safely increase vacuum levels to milk cows faster

Paradigm shift

The dairy industry is steadily shifting to milking cows between the back legs. This has some advantages but does make unit alignment more difficult and can lead to uneven milkouts. The natural curve of the milk hose often twists the claw, resulting in one quarter overmilked and the opposite quarter undermilked.

Also, the claw can be pulled backward due to the weight of the milk hose if no curb support is used. This causes machine-stripping and overmilking of the front quarters.

Engineering hose supports on the curb and rotating the milk hose to use its natural curvature for correct unit alignment are important design and maintenance steps on parallel and rotary parlors. Rotary parlors present unique challenges for hose supports because of the cows entering and leaving the table.

Now let’s identify the fast-wearing components in all milking parlors, their recommended change frequency and my “watch list” comments based on field experience.

Rubber goods

With an ever-increasing variety of materials, the frequency for changing rubber goods is a confusing topic. All rubber goods change schedules must be established based on the specific products used and tracked in your scheduled maintenance log book.

Thumb rules for rubber goods changes include:

-

Milk hoses, short pulsation tubes, twin pulsation tubes: Six months (silicone lasts longer)

-

Liner replacements: Follow manufacturer’s recommendation

- Gaskets, seals, milk contact rubber parts: Follow manufacturer’s recommendation

Dr. T’s watch list:

1. I prefer clear, twin air tubes because they allow visual monitoring of contamination (milk, dirt, post-dip, etc.) inside the hoses, which requires immediate attention.

2. Dirty twin air tubes will affect pulsator performance by up to 10 percent from frictional resistance.

3. If when you change liners you notice a significant improvement in milking performance (speed, fewer squawks, etc.), you need to decrease the number of milkings per change.

4. Silicone milk hoses do not last forever.

5. “Shocking” your system to solve a cleaning problem will significantly decrease the life span of all rubber goods … so adjust accordingly.

Regulators, VFDs and vacuum pumps

There are a variety of regulators and variable frequency drives (VFDs) found in parlors today. Along with the vacuum pump itself, all of these pieces of equipment are working constantly and become dirty and wear out over time. Establish the frequency you need to clean your regulators, service your vacuum pumps and check your VFDs and keep up with their scheduled maintenance.

Thumb rules for regulator and VFD maintenance include:

- Monthly cleaning of regulators

- Quarterly or biannual changing of filters

- Regular maintenance of vacuum pumps (include lube and belt checks)

- Less than six-hour-per-day parlors need an annual complete National Mastitis Council-based system analysis

- More than 15-hour-per-day parlors need a semi-annual complete National Mastitis Council (NMC) analysis

Dr. T’s watch list:

1. Warm weather creates tremendous dirt buildup in parlors. Filter change frequency must be increased.

2. Vacuum pumps decrease their rate of air removal (CFMs) as they age. This is hard to detect without an NMC air flow system analysis.

3. If you upgrade from 5/8” to 3/4” milk hoses and pipeline inlets, request an NMC effective reserve test … your parlor may be short of vacuum with the larger milk inlets.

Pulsators

There are many types and styles of pulsators on the market today. Most are electronically controlled and operate with two channels.

The massage phase of the pulsation cycle (D phase) has a specific recommendation listed in the NMC air flow manual. A minimum of 150 milliseconds (mS) is recommended.

Most equipment consultants today believe cows are more comfortable with D phases greater than 200 mS to minimize blood congestion in the teat. Just recognize that next to the vacuum pump, pulsators are logging the most hours annually.

Thumb rules for pulsator maintenance include:

- Direct pulsators need cleaning and re-kitting every 2,500 hours.

- Indirect pulsators need cleaning and re-kitting every 4,500 hours.

- Pulsators need to be graphed regularly (establish frequency with your dealer).

- Pulsator monitoring systems can be an asset if they are dependable.

Dr. T’s watch list:

1. If when you graph pulsators you constantly find several out of tolerance or non-functional, it may be time to stop rebuilding and upgrade your whole pulsation system.

2. The technology with some of the newest pulsators and control boards is better than the previous engineering; it warrants a close look at the benefits of upgrading.

3. A new frontier with pulsator settings is to adjust not only the ratio but the rate as well. A lot of older control boards have limited adjustability and therefore limit some of the newer settings that research is now suggesting.

Inflations

Inflation choice is confusing because of all the different shapes and materials. However, it is important because it is the one part of the milking system that directly touches the cow. The liner’s ultimate performance is directly affected by its design features and is indirectly affected by the pulsators and system vacuum level.

The excessive pinch (overpressure) that a liner puts on the teat end increases the risk of developing hyperkeratosis (rough teat ends). Interestingly, new research now indicates that teat health and specifically blood congestion in the teat wall and the annular ring at the base of the teat have an impact on increased clinical mastitis risk.

Because of this research, the choice and system settings of a liner should include answers to the following questions:

- What is the shape of this liner?

- What material is this liner made of?

- What is the internal bore size of this liner (large, medium, narrow, taper)?

- What average claw vacuum should the system be set at for this liner?

- What is the average overpressure of this liner at this vacuum level?

- How much squawking will I get at this vacuum level with this liner?

- What B and D phases are recommended for this liner?

- How much ringing (mouthpiece vacuum) will I get with this liner?

Thumb rules for liner choices include:

- Large-bore liners milk fastest but create the most risk of ringing.

- Narrow-bore liners produce the least ringing but milk the slowest.

- Two ways to milk a cow faster – higher vacuum or longer B phase (Both of these adjustments have points of diminishing returns.)

- Research has now shown that with a certain liner, a new way to milk a cow faster is to increase the pulsation rate to produce more B phases (the highest flow rate is at the beginning of each B phase), not longer B phases.

Dr. T’s watch list:

1. Reducing ringing by reducing mouthpiece vacuum buildup is an important goal. Ringing happens when vacuum passes around the teat during periods of low milk flow (no milk in the teat sinus to push the teat wall against the liner wall and create a seal).

2. Square liners have four corners where vacuum can pass around the teat so they are prone to ringing; typically, they require a lower claw vacuum to reduce the risk of ringing.

Find a person who you can trust to advise you on equipment choices and the current “state of your milking parlor.” Then you can make a well-informed decision regarding maintenance and upgrade needs for this very important piece of equipment on your dairy. PD

Roger Thomson provides “intelligence for a quality milk harvest” through his consulting practice based out of Battle Creek, Michigan.

PHOTOS

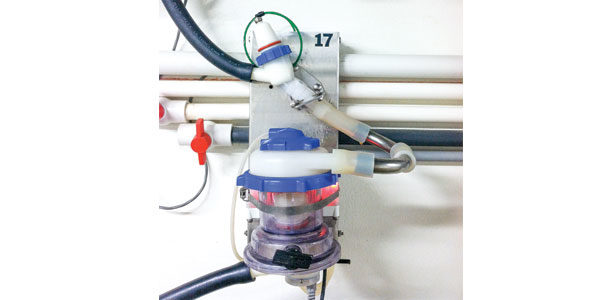

PHOTO ONE: An excellent pathway of milk that allows milk to flow “downhill”

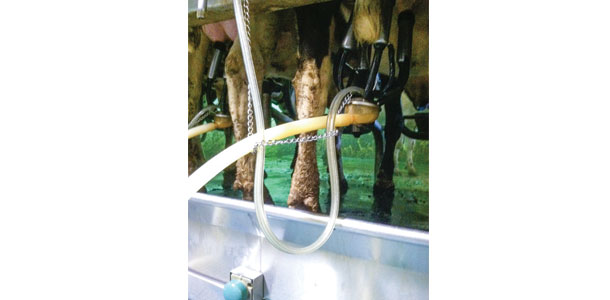

PHOTO TWO: This mixed pathway of milk shows excellent curb support and flow from claw over

the curb; however, the milk hose is too long and loops going into the subway.

PHOTO THREE: Poor unit alignment milking between the back legs could lead to uneven milkouts.

PHOTO FOUR: This milker-engineered unit alignment system is not a good solution.

PHOTO FIVE: The inking of this jetter cup indicates this rubber good needs to be replaced.

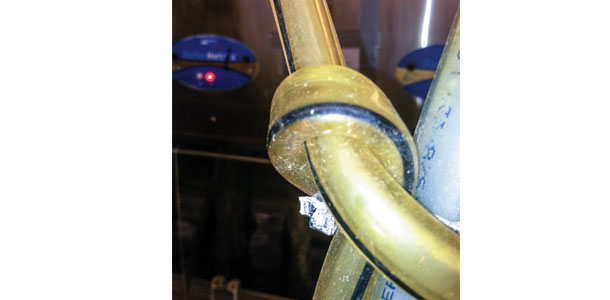

PHOTO SIX: The loop restricts flow in a long pulsation tube.

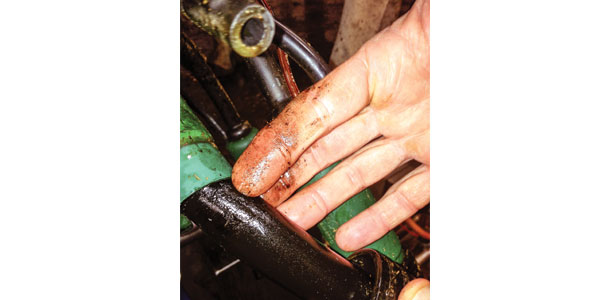

PHOTO SEVEN: Not only is this an old and cracked milk line, it enters a broken flow sensor repaired

with vet wrap, which is typically reserved for hoof repair.

PHOTO EIGHT: A warped mouthpiece opening signifies a replacement is needed.

PHOTO NINE: Two different shells using the same liner produces different tensions and is bad.

PHOTO TEN: Iodine post-dip in the pulsation chamber is bad for the liner and the pulsator. Photos courtesy of Roger S. Thomson.

Roger S. Thomson

Veterinarian

MQ IQ Consulting