Editor’s note: This is the first article in a two-part series. In the competitive march toward improved efficiency and profitability, many dairymen have long recognized the high cost of their milking center can best be justified by running it 24 hours a day. At this pace, your parlor is on the clock in excess of 8,500 hours per year.

Compare this to your busiest tractor, loader, truck or skid steer, and the obvious conclusion is … you are likely behind on routine parlor maintenance and possibly overdue for some equipment upgrades.

In visiting farms around the country, it is always fun to ask a dairyman, “How old is your parlor?” Often chin-rubbing and forehead-wrinkling is combined with a recollection of when children were born, graduations or marriages – and the ultimate answer is 10 or 20 or 30 years with the surprised declaration, “I didn’t think it was that old.”

When well cared for, a parlor can be maintained in a very good-looking way that hides its age. So, I ask you right now to stop reading and determine the age of your parlor. Write it down. And while you are at it, list and date the major upgrades or remodeling you have done since your parlor was built.

If at best you are guessing to answer these questions, you need to implement a “master notebook” system to track your parlor’s performance and maintenance activities. Have you ever watched an airplane maintenance technician work through a problem?

He has a detailed notebook for all possible equipment problems and how to repair that problem for each type of aircraft, and a repair log-book to detail the specific work done on the specific plane he is servicing.

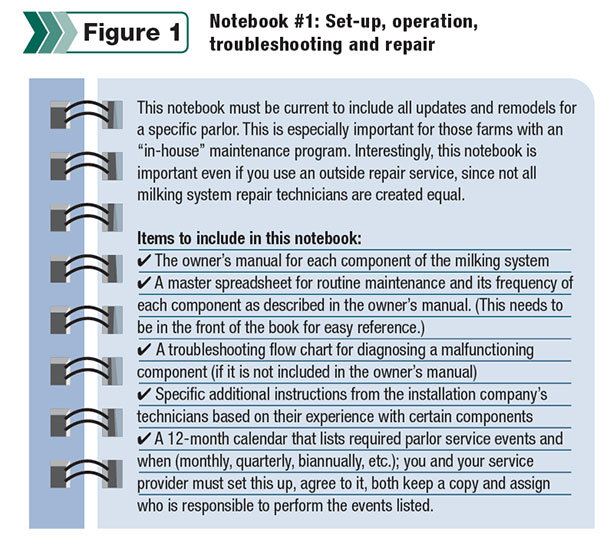

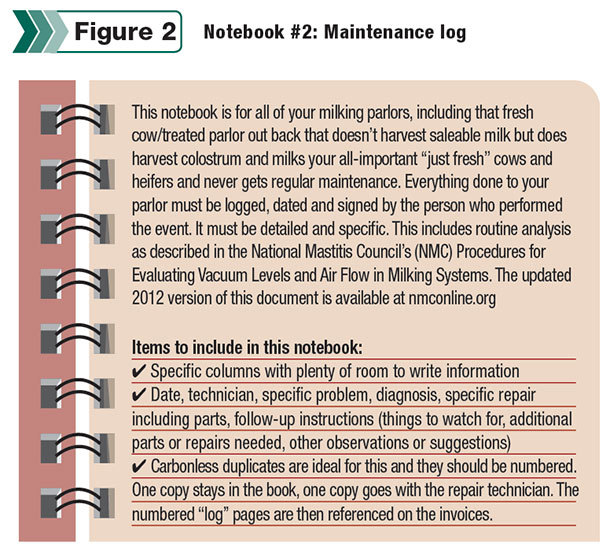

Once the repair is accomplished, the plane does not move until the technician completes a detailed report of what he has accomplished. You need this same type of documentation for your parlor. In conjunction with your equipment team, create two notebooks following the instructions in Figures 1 and 2 .

Now, back to the revelation that your parlor is older than you thought. Time has produced many improved technologies for milking systems that are worthy of consideration. My top three reasons to update a milking system are:

1. Improve mastitis control and milk quality

• Reduce or eliminate the retrograde flow of milk against the teat end during milking.

• Reduce all factors that cause teat congestion. (Research now shows a strong correlation between teat congestion and increased somatic cell counts.)

• Eliminate all design issues that degrade the CIP event for your parlor.

• Add a duplicate milk filter system and change filters every four hours to reduce standard plate counts. (Bacteria grow constantly in milk filters.)

• Improve lighting so milkers can see the teats they are to clean.

2. Improve milking performance (speed and completeness of milk-out)

• Eliminate milk lifting in the “pathway of milk” from the teat to the milk line.

• Eliminate bottlenecks to correct unit alignment (especially when milking between the hind legs).

• Set claw vacuums and B phases to maximize the performance of your liner choice based on research. (Ask your liner supplier for data.)

• Make changes that reduce the A and C phases of your pulsation system to maximize the opportunity to increase the speed of milk-out with pulsation setting changes. (All pulsators are not created equal.)

• Upgrade pulsation control board to allow both rate and ratio adjustments.

• Eliminate ringing at the base of teats to reduce blood congestion.

• Improve lighting so milkers can see the teats they are to clean.

3. Improve efficiencies and general aesthetics

• Decrease energy consumption.

• Lower system vacuum without affecting the speed of milk-out to increase the vacuum pump life span.

• Improve air quality in the parlor and mechanical room to reduce dirt build up in the regulator, vacuum pump and all filters.

• Improve lighting so milkers can see the teats they are to clean. PD

Editor’s note: In the second article of the series, the author will identify fast-wearing components, their recommended change frequency and personal “watch list” comments based on field experience. Look for this article to appear in the October 1, 2014 issue of Progressive Dairyman .

Roger Thomson provides “intelligence for a quality milk harvest” through his consulting practice based out of Battle Creek, Michigan.

Roger Thomson

Veterinarian

MQ IQ Consulting