Alfalfa haylage is a staple in the diets of high-producing dairy cows due primarily to its significant contributions of crude protein and physically effective fiber in most TMRs. However, it remains one of the most difficult and challenging forages to ensile properly.

Alfalfa is especially challenging to ensile due to its buffering capacity and critical moisture thresholds. The vast majority of alfalfa is harvested correctly and ferments properly, but we still see about 5 to 15 percent that “goes butyric” due to clostridic fermentation.

Numerous factors affect silage quality, including moisture (dry matter content), forage buffering capacity, ash content, temperature, total protein and gas-filled porosity (air or oxygen) in the silo. Although some of these factors are beyond our control, several factors can be managed and represent critical control points (CCP) for making high-quality alfalfa haylage.

CCP 1 – Maturity

Typically, tons of dry matter per acre is the metric used when evaluating the success of various forage production scenarios. Unfortunately, with advancing alfalfa maturity, yield increases but digestibility decreases. Thus, the optimal metric should be tons of digestible dry matter per acre.

Minimize the indigestible tons that are harvested, hauled, stored and fed in order to improve overall efficiency. Low-lignin alfalfa varieties may provide considerable harvest flexibility related to maturity and digestibility.

CCP No. 2 – Moisture

Regardless of maturity, the single-most important criterion for successfully ensiling alfalfa is moisture.

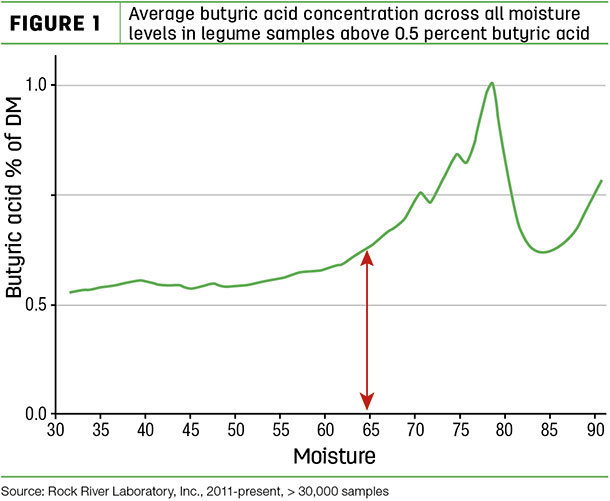

At 65 percent moisture or higher (less than or equal to 35 percent dry matter), there is increased risk of butyric acid formation, indicative of clostridic fermentation (Figure 1).

This mal-fermentation leads to a reduction in sugar, elevation in pH, degradation of protein, increase in dry matter loss, “off” odors and poor feedout performance with potential health effects when fed to high-producing dairy cows.

The excessive moisture in alfalfa leading to clostridic fermentation could be inherent to the crop at harvest due to improper wilting time, deep windrows or rain or heavy dew.

Target dry matter for alfalfa haylage ideally should be 38 to 42 percent (58 to 62 percent moisture) in order to minimize the likelihood of clostridic fermentation, but realize that actual dry matter going into the bunker or pile realistically will fall between 35 and 45 percent (55 to 65 percent moisture) for this target.

Nonetheless, by targeting about 40 percent dry matter, the vast majority if not all alfalfa harvested for silage will be at a moisture detrimental to widespread growth of clostridia.

CCP No. 3 – Contaminants

In addition to maturity and moisture, the other practical concern for making high-quality alfalfa haylage is contaminants. Soil contamination of alfalfa is deleterious for two reasons: It accumulates indigestible ash that serves as “filler” in a nutrient-dense TMR, and the potential for higher numbers of clostridia spores and enterobacteria to be ensiled with the forage.

Both may potentiate undesirable fermentation and could be contributing to pathogen load consumed by dairy cows.

Clostridia contamination of forage, primarily wet alfalfa haylage, leads to extensive dry matter loss, elevated butyric acid levels and potential negative impacts, especially for fresh and transition cows.

While clostridia species that produce butyric acid in silage (e.g., butyricum, tyrobutyricum, sporogenes, etc.) can be reduced and effectively controlled with a reputable bacterial silage inoculant and improved management practices, Clostridium perfringens also may be present and can have significant anti-nutritional effects on high-producing dairy cows.

Enterobacteria such as salmonella, E. coli, Klebsiella and Shigella are organisms typically found in human and animal intestines. These organisms are undesirable in silage because they compete with beneficial bacteria for nutrients prior to and during ensiling.

Their growth is known to increase the buffering capacity of the crop once ensiled, which raises the pH and lowers aerobic stability. Conversely, enterobacteria are essential for the degradation of nitrate (NO3) to other nitrogenous compounds that can inhibit the growth of clostridia and reduce the production of butyric acid.

Clostridium perfringens and enterobacteria have been implicated in hemorrhagic bowel syndrome as well as other digestive disturbances. The loss of cows is obvious, but what about the chronic subclinical losses that occur daily without noticeable effect? Are you providing your cows with “clean forage?”

Higher-than-normal ash levels in alfalfa haylage can be a result of picking up additional ash from the soil during mowing, wilting, windrowing and chopping or substantial dry matter (sugar) losses due to a secondary fermentation event. We are harvesting alfalfa as highly digestible nutrients for high-producing dairy cows; we are not landscaping.

It may be necessary to raise the cutter height and slow mowing speed. Raising the cutter height (i.e., from 2.5 to 3.5 inches) will reduce total dry matter yield but will increase dry matter digestibility. Mowing at slightly slower speeds will reduce the amount of scalping due to “bounce” of the haybine or discbine. Both measures may serve to reduce the unnecessary inclusion of additional soil and ash.

CCP No. 4 – Inoculant

Apply a science-based, research-proven bacterial forage inoculant designed specifically to inhibit clostridic fermentation. Reputable companies will gladly share their controlled research and field observations when asked.

CCP No. 5 – The bunker

The final CCP focuses on diligent management at the bunker, pile or storage structure. Additional avoidable losses can range from 10 to 30 percent and occur at the bunker when attention to detail wanes. Oxygen is the enemy.

These steps are necessary to achieve and maintain oxygen-free conditions vital to successfully ensiling alfalfa.

- Empower one person to make the call when conditions deviate from standard operating procedures.

- Fill the bunker or pile rapidly to minimize losses due to plant respiration.

- Match harvested alfalfa delivery speed to the bunker or pile to what the push tractor and packing tractors are capable of handling.

- Ensure sufficient packing tractor weight to obtain bulk density greater than 45 pounds per cubic foot, as fed.

- After the last load is delivered and packed, get off the bunker or pile. Additional time spent on the bunker or pile will not necessarily improve dry matter density.

- Completely seal the bunker or pile. Time is money in the form of lost nutrients due to exposure to oxygen.

Specific attention to these CCPs can enhance yield, fermentation and preservation of higher-quality alfalfa haylage. ![]()

-

Keith A. Bryan

- Global Technical Portfolio Manager

- Chr. Hansen Inc.

- Email Keith A. Bryan