When looking for ways to increase income over feed cost, the results other herds have obtained by balancing amino acids can provide insightful direction. With U.S. corn-based rations, the two amino acids that are first-limiting are methionine and lysine.

Supplementation with rumen-protected methionine (RP-Met) and lysine (RP-Lys) is now common. With methionine supplementation, we are seeing a trend to a 0.1 percent increase in milk protein for every 10 g of methionine supplementation when rations are methionine deficient.

With lysine, a comparative newcomer, usage trends and recommended practices are emerging.

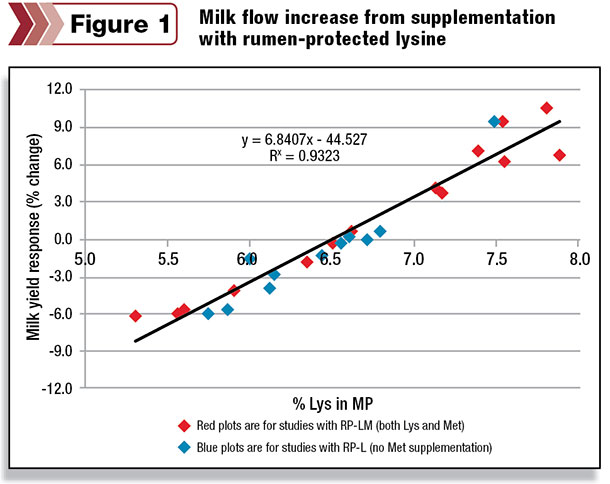

Several published abstracts show an increase in milk flow from lysine supplementation. Figure 1 depicts the abstracts resulting from research by my company on our RP-Lys product. Several of the trials were conducted using only RP-Lys; others included RP-Met too.

As you can see, as the percentage of lysine in the metabolizable protein (percent Lys MP) increases, there is a constant increase in milk yield response. Many of these trials were done in early and high-lactation groups and resulted in a consistent response.

From this dataset, we can derive that every 1 percentage point increase in Lys MP could result in a 6.8 percent increase in milk volume.

How does this translate in the field? After observing and tracking several herds, the following lysine-usage practices are becoming apparent:

- Adding amino acids to the ration; no other alterations

- Removing some blood meal or protein feed; adding RP-Lys

- Removing all blood meal; adding RP-Lys

- Removing blended protein products; adding RP-Lys

Adding lysine; no other alterations

Adding lysine on top of the existing ration typically fails, based on our on-farm experience. Herds typically saw no response. Why?

The diet likely was not limiting in lysine; consequently, the lysine added was metabolized into something else the cow needed, such as energy. While feed costs increased, no additional revenue was generated. Those herds that did sense a response had rations deficient in lysine (g less than 165).

Remove some blood meal or protein feed

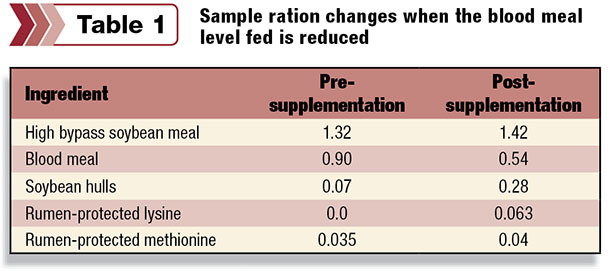

Removing some blood meal or protein feed typically provides cost savings thanks to the use of a synthetic form of lysine. Space also opens up in the diet for other, cheaper feeds.

The ingredient changes that occur with this approach appear in Table 1. As you can tell, blood meal was reduced. In the new space, soybean products were increased for this 1,500-cow herd. The methionine source was adjusted to maintain the proper lysine-to-methionine ratio.

Research recently completed comparing the models have indicated that lysine to methionine can be 2.7 to 1 for optimal results when utilizing a Cornell-based system and closer to 3 to 1 when utilizing a ration formulation system based on the National Research Council (NRC) recommendations.

Research recently completed comparing the models have indicated that lysine to methionine can be 2.7 to 1 for optimal results when utilizing a Cornell-based system and closer to 3 to 1 when utilizing a ration formulation system based on the National Research Council (NRC) recommendations.

-

Diet specifications – The crude protein of this diet was reduced by 0.3 percent, the lysine was reduced by 2 g, methionine by 4 g, and the lysine-to-methionine ratio increased from 2.61 to 2.76. Some things stand out.

The total grams of lysine and methionine did decrease in this diet. This occurred because the lysine-to-methionine ratio was corrected, and the amount of lysine being provided by the blood meal is unknown. So the diet may have resulted in an increase in lysine that caused the production response.

-

Return on investment – Positive results were obtained from both a cost savings and production standpoint. The diet cost decreased from $5.75 to $5.74. Milk yield increased from 80.5 pounds to 81.5 pounds.

Butterfat percent increased from 3.58 percent to 3.7 percent, and protein increased from 3.03 percent to 3.13 percent. Milk urea nitrogen decreased from 10.4 to 9.2.

Remove animal byproduct feeds

With the true methionine and lysine needs for the high-producing dairy cow being somewhat of a mystery, some nutritionists raised the question of what the next limiting amino acid is and whether we need to make sure we are meeting those requirements. Does this mean there is a need to keep some animal protein in the diet?

Research conducted by professor Alex Hristov at Pennsylvania State University has shown that at low crude proteins (13 to 14 percent), histidine likely becomes limiting. It would be unlikely to see levels that low in the field. However, environmental concerns could become an influencing factor here.

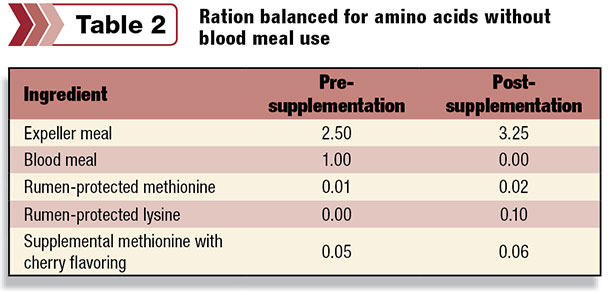

Table 2 shows an example of a multi-thousand-head dairy whose nutritionist took the above approach. He felt consumer sentiment would prevent the use of animal proteins at some point.

The extra diet space was filled with lysine supplementation and expeller meal. The methionine level was adjusted to maintain the proper ratios.

-

Diet specifications – With this diet, crude protein decreased from 16.7 percent to 16 percent. The lysine grams went from 175 to 185, methionine from 59 to 61, and the lysine-to-methionine ratio changed slightly from 2.96 to 3.01.

- Return on investment – The return on investment was twofold. Price decreased from $7.29 to $7.02, and milk flow increased from 97.5 to 97.8 pounds. Butterfat increased from 3.5 to 3.6 percent, and protein increased from 3.03 to 3.05 percent. Milk urea nitrogen remained at 10.0.

Remove blended product

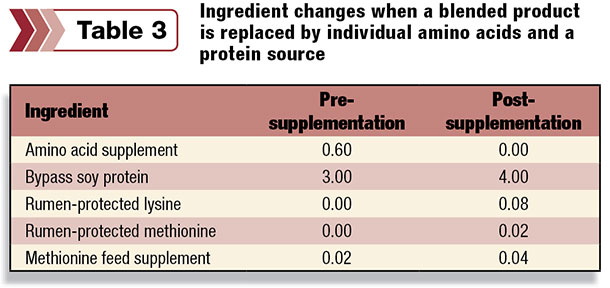

Commercial, blended amino acid products have helped change the production scene in high-producing herds, enabling them to reach higher production levels (Table 3).

These products typically are a blend of a proprietary blood meal that has less variation and sometimes a rumen-protected lysine, methionine or both to provide a fixed amount of amino acids.

These products typically are a blend of a proprietary blood meal that has less variation and sometimes a rumen-protected lysine, methionine or both to provide a fixed amount of amino acids.

-

Diet specifications – The diet specifications for a typical 150-cow Midwestern dairy did not change between the two diets. Crude protein remained at 17.5 percent. Lysine g stayed at 185, methionine g at 65, and the ratio at 2.85. Changes were not the goal of the nutritionist, as many times the single ingredients are what comprise the commercial product.

However, sometimes there are benefits to a blended product that can’t be achieved through individual amino acid supplementation. For example, a high-producing herd giving 100 pounds of milk would need the consistent blood source found in these products.

- Return on investment – No performance change occurred when a blended product was replaced with supplemental lysine and methionine. Milk flow remained at 77 pounds, butterfat percent at 3.6 and protein percent at 3.1. The cost reduction from $6.21 to $5.91, however, supported income over feed cost.

What we know – what we don’t

Do we know everything about amino acids balancing? We have come a long way. Trends and key principles for amino acid balancing are developing.

- Protein level targets are: prefresh 1,300 grams of Lys MP, and fresh cow and high cow MP target at 98 percent of required model predictions.

- Provide sufficient rumen-degradable protein to maximize microbial yield.

- Confirm that your RP-Met and RP-Lys match the manufacturers’ specifications.

- Make sure starch levels provide enough energy to drive the production of amino acids.

- Focus on prefresh cows too. Ample research shows methionine improves immune function. However, maintaining the proper lysine-to-methionine ratio is essential to ensure excess methionine is not converted to something else needed by the cow.

- Know your ration formulation system to know if your lysine-to-methionine ratio should be 2.7 to 1 or 3 to 1.

Amino acid balancing will be critical in the future if markets are down, up or in between. Amino acids are essential nutrients. They directly impact animal production and performance. PD

-

Jessica Tekippe

- Product Manager

- Ajinomoto Heartland Inc.

- Email Jessica Tekippe