What separates the top-performing herds from the bottom? This is one of those questions people are constantly asking and attempting to answer. As a result, we have a multitude of complicated calculations measuring everything from energy-corrected milk to income over feed costs.

From my perspective as a dairy nutritionist, it’s fairly simple: The best herds I work with are the ones that produce components the most efficiently and, as a result, are usually the most profitable.

Efficiency is something many dairy producers focus on, and oftentimes they can tell you how efficient they are at things like parlor turns and employees per cow.

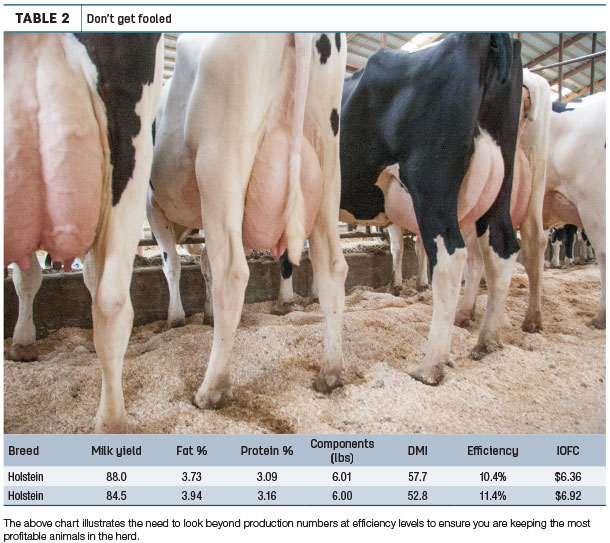

However, when it comes to the component efficiency of their cows, many are at a loss. Most dairymen can tell me which cow makes the most milk, but that doesn’t really tell me if that cow is the most efficient and profitable animal on the operation.

To really understand what makes a herd efficient and therefore profitable, we first have to understand what a dairy is really selling. Many producers are trapped by the misconception they are in the business of selling milk. When you look at a milk check, though, the value is calculated on the fat and protein components within the milk.

These components are what processors are really buying because these components are what’s used to produce the majority of dairy products (butter, cheese, etc.) consumers purchase. The rest of the milk is basically water that gets separated out.

This common misconception can lead producers to make costly mistakes by skewing the way they think about their operation and value their animals. The best dairy producers understand they are in the business of selling fat and protein, and they focus on doing this as efficiently as possible.

Once a dairy producer transcends their thinking to this level, they start to value cows based on how efficiently they convert feed and forage to fat and protein components, not just simply milk production. Component efficiency is a biological gauge of how well the rumen is functioning at the conversion process, and it helps us determine if we are working with a herd of all-stars or bench-warmers.

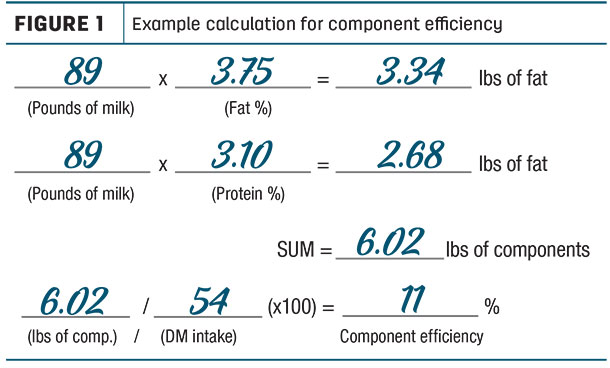

Calculating component efficiency is fairly simple: Divide pounds of components by pounds of dry matter intake and multiply by 100. When we are limited by how many cows we can house and feed, we must ensure we are housing and feeding the cows that are the most efficient at what we want them to do: make milk components.

I work with herds in three states, and the component efficiency ranges from 9 to 12 percent. In 2016, the average price of Class III milk components (fat + protein) was $2.21. That means for herds that improve their component production by one point (5.0 to 5.1), income increases by 22 cents per head per day.

When I start working with a new herd, I use these numbers to illustrate the value that can be realized when they focus on component efficiency. It’s not a quick fix, one and done. Focusing on component efficiency requires a whole-farm approach. There are two ways to improve component efficiency: increase component production or decrease dry matter intake.

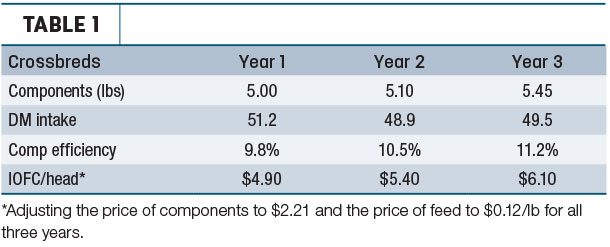

One of my crossbred herds embraced this theory when we began working together, and we refocused management to ensure everything employees did was geared toward improving component efficiency. At year one, they were producing 5 pounds of components, and we calculated efficiency at 9.8 percent, based on a dry matter intake of 51.2 pounds.

For the first year, we focused on decreasing the dry matter intake by providing more nutrients in every bite. As a nutritionist, I formulate rations based on nutrient needs, not ingredient requests.

If you are going to focus on component efficiency and make every bite count, every bite has to provide the nutrients required for health and productivity. Otherwise, you are wasting bites.

On year two, the dry matter intake had dropped to 48.9 pounds per day, and components increased to 5.1 pounds, moving efficiency to 10.5 percent. Income over feed cost per head per day improved by 50 cents. When a producer experiences that level of improvement, they become true believers, and this one was eager to see what more we could do.

Knowing my colleagues work with several herds that push the envelope on component production – achieving 6, 7 or more pounds of components – we focused on increasing the component production in the third year. Intake directly affects production, so we had to slightly increase the dry matter intake, but components increased to 5.45, once again increasing efficiency and, this time, resulting in 70 cents increase in income over feed cost per head.

This herd is well on their way to being one of my top-performing and most efficient because they have taken a focus and disciplined management approach dedicated to efficient component production.

That is what it takes to become one of the extremely elite herds, those achieving 12 percent component efficiency. These dairies implement a whole-farm approach focused and disciplined. They understand component production and efficiency is about making every bite count.

They thoughtfully consider the critical elements impacting component production, from calf-feeding programs that focus on developing the rumen for maximum efficiency to controlling forage quality from seed selection to chop length. They don’t just do one or two things well; they do everything well with the goal of making every bite count toward efficient component production.

When it comes to measuring the success of your dairy operation, skip the frustration and forget the multitude of complicated calculations and coefficients. Focus on component efficiency. Figure out where you are today and where you want to be in the future. ![]()

-

Shane Holt

- Dairy Focus Consultant

- Cargill

- Email Shane Holt