A 450-cow dairy in Hawley, Minnesota, will be test-driving a body condition scoring camera in 2017 as soon as its remodeled freestall barn and new milking robots are installed early this summer.

Blumenfeld Holsteins will install DeLaval’s BCS camera inside their eight new milking robots. The dairy has agreed to ongoing interviews this year about their experience with the new technology.

“The BCS camera should give us an unbiased body condition score,” says Brian Waldner, the dairy’s herd manager. “We can then better gauge how the herd is doing given ration changes, milk production levels, etc.”

The dairy currently monitors body condition scores monthly; the dairy’s nutritionist does the scoring.

“We’re not concerned about our body condition scores, but we think we can still improve from where we are at now,” Waldner says. “If we can just respond to changes in a more timely manner and get an intervention going sooner than we otherwise would have, it will be worth it.”

Waldner says he doesn’t doubt the technology can accurately gauge a cow’s body condition score automatically. He’s more interested to see how the dairy uses the automated scores to develop intervention strategies.

“For example, if we see BCS is trending downward, what will we do?” Waldner says. “I’m interested to see how long it will take us to learn how to counteract what we observe. We do feel we will be able to respond to changes in a more timely manner than we do now.”

The dairy is specifically interested in tracking scores for dry and fresh cows. Waldner says he will be watching how these cows’ scores change from dry-off through the first 20 days in milk. He hopes by monitoring the scores and developing intervention strategies, he can improve the herd-average days to peak milk, one of the performance metrics the dairy follows closely.

The dairy’s current days to peak milk for first-lactation cows is 92. Second- and third-lactation cows are at 67 and 70 days, respectively. In addition, the dairy also tracks pounds at peak milk. First-lactation cows peak at 85 pounds, while second- and third-lactation cows are at 112 and 120 pounds, respectively.

“These metrics basically gauge how well we transition an animal from dry to lactating. Whenever there are issues in that time frame – be it at two days, 14 days or 40 days in milk – those hiccups will affect peak milk,” Waldner says.

He believes the body condition scoring camera, as well as some of the other automated features of the new milking robots – such as daily per-quarter conductivity scores – will help improve production and efficiency. The success of the new technology’s installation will be determined based on its overall impact on milk production.

The herd is currently averaging 93 pounds of milk per cow at 2X-milking and no rbST. Waldner says he hopes the robots will enable the dairy to average 3X-or-above milking. The dairy intends to understock its 60-head pens with the goal of getting more total pounds from increases in pounds of milk per cow. Pen groups will have 55 cows.

“We want to be more efficient and have our cows get milked a little more often,” Waldner says. “We would prefer to get more milk per cow rather than push more cows through the robot and get less milk per cow.”

The dairy hopes to be able to get to 105 pounds per cow after its latest round of investments. Waldner and the dairy’s nutritionist and veterinarian are the key members of the dairy team who will be evaluating the technology’s success.

“We think milk production is a good gauge for whether something worked or not. We know there are a thousand variables that influence that number, but over time, they tend to sort themselves out,” Waldner says. “105 pounds – we don’t want to stop there, but that’s the first goal with this new technology.”

An upgrade to the dairy’s milking equipment is added on top of the dairy’s emphasis on the basics – high-quality feed and great genetics. The dairy grows all of its own forages – including corn silage, alfalfa and grass – on 850 acres and milks only registered Holsteins.

“It’s important to get the best genetics possible,” Waldner says. “You have to have that potential first. Then with feed quality and management, you can harvest that potential. The better the feed you can put up, the more the cows will put in the tank.” ![]()

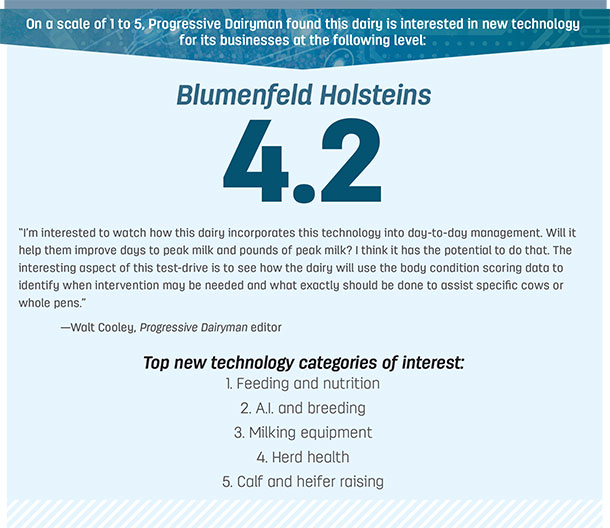

-

Walt Cooley

- Editor-in-chief

- Progressive Dairyman

- Email Walt Cooley