When Lawnhurst Farms outgrew its bedding recovery unit – a mechanical dryer – it decided it was time to take the next step to produce more bedding for the dairy.

Click here or on the image above to open it at full size in a new window. (PDF, 543KB)

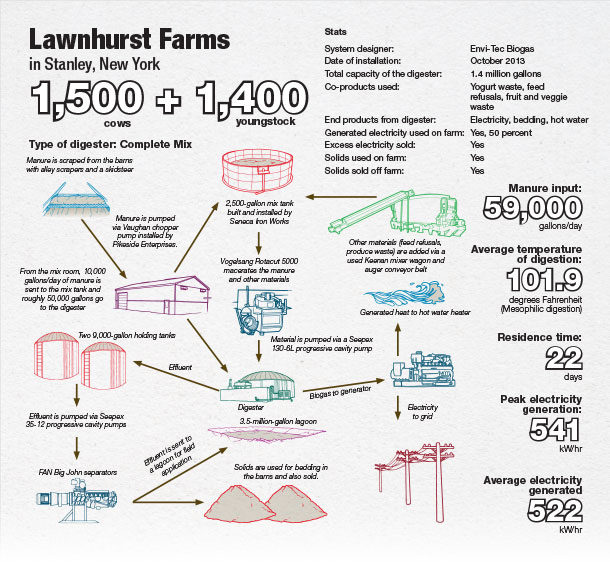

An anaerobic digester would process more bedding as well as help the farm get more out of its manure. “It was a resource we were not fully utilizing,” says one of the farm’s owners, Don Jensen III.

In addition, a digester would portray a positive image for the dairy industry and help reduce the farm’s carbon footprint.

Then there were the monetary benefits. The farm gains additional revenue from sales of electricity and digested solids, which are sold to neighboring farms as bedding and to a general trucking company that distributes it mainly as fertilizer. The farm has also eliminated its purchases of electricity and LP for heating water.

According to Jensen, the farm already had 300,000 gallons of manure storage built on the dairy and 7 million gallons of lagoon space, so adding in the digester wasn’t as complicated as it could have been without those features. It also had a building to house the separation equipment and store the separated solids because of its previous manure and bedding recovery system.

Altogether, those items reduced the capital required for the project, leaving the biggest expense as the digester itself. Jensen says another significant expense was upgrading the electrical service at the farm to handle the power generated from the methane.

The farm is happy with how the system has been operating for nearly two years. “From a mechanical standpoint, things function extremely well,” he says.

After looking at digesters developed by many different manufacturers and taking a trip to Germany to see more, Lawnhurst Farms opted for this complete mix system.

“We did our research and our due diligence,” Jensen says.

For others contemplating a similar project, he advises, “Don’t sign with the first guy that pulls in your driveway. Consider it like you would any other major decision – like purchasing a new herd or putting in a new parlor.”

Lawnhurst Farms was able to obtain state and federal grants, which helped make the project financially feasible.

“The return [on a digester] is slower than most investments,” Jensen says. “We were prepared for that, but the grant funding played a huge role. There’s a good chance we would have reconsidered if there had been zero grant money.”

He mentions the future of funding for projects like these is uncertain, but it takes these types of incentives to perpetuate the installation of more anaerobic digesters on dairy farms.

It would also help if there were a way to streamline working with utility companies, he says. Waiting on the utility company was time-consuming and a big struggle in seeing this project to completion.

With the digester in place and running well, Jensen says there is nothing major he would want to change. PD

-

Karen Lee

- Editor

- Progressive Dairyman

- Email Karen Lee