When the Professional Nutrient Applicators Association of Wisconsin (PNAAW) formed a decade ago, it identified road and bridge issues as one of its top three priorities. The problem is that all types of farm equipment are getting larger and larger, while town roads are not designed to handle large and heavy loads. To find out what was really happening to the roads, PNAAW initiated a four-state, four-year $630,000 study. Partners in this endeavor included the state Departments of Transportation for Iowa, Illinois, Minnesota and Wisconsin; Professional Dairy Producers of Wisconsin; Minnesota Pork Producers and other agribusinesses and associations.

Industry, including manure applicators, farm equipment manufacturers and tire manufacturers, stepped forward to lend equipment, experienced drivers and technical expertise.

Kevin Erb, conservation professional development and training coordinator with the University of Wisconsin Extension , oversaw the study and has taken to the road himself to share the results.

The main objective was to determine the pavement response to selected agricultural equipment compared to the pavement response of a typical 80,000-pound, five-axle semi tractor-trailer.

Working at a Minnesota Department of Transportation test site, the group tested at three times of the year – when frost comes out of the ground in early March, the driest part of the year in August and a mid-point temperature time in November.

Four types of pavement were tested:

• Cell 84 (thick) – 5.5 inches of hot asphalt, nine-inch gravel base

• Cell 83 (thin) – 3.5 inches of hot asphalt, eight-inch gravel base

• Cell 32 – five inches of concrete, six-inch gravel base

• Cell 54 – 7.5 inches of concrete, 12-inch gravel base

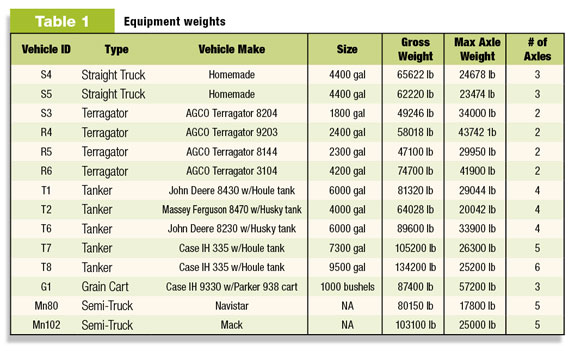

A wide variety of equipment was tested from 4,400-gallon tank trucks with radial or flotation tires to tractors pulling a 4,000-gallon dual-axle tanker up to a 9,500-gallon, quad-axle tanker, as well as terragators and a truck used by municipalities to haul sewage sludge.

Results

“Pavement damage did occur under certain conditions but not under others,” Erb says.

Some observations included a wet spot in the subgrade of the thin asphalt that gave out early and propagated damage quite a ways out throughout the testing. The concrete cracked as well in the spring of 2008 and 2009.

It was patched, but they did not get a good take on the repair so the section blew out almost immediately with the first few loads in August.

Erb reports the key variables for road damage include axle weight, distance from the edge of the pavement and how the road is constructed and its drainage.

Axle weight

Axle weight was found to be a main factor in the study, more so than total vehicle weight ( see Table 1 ).

Erb points out that the Case IH 335 with 9,500-gallon Houle tank had a gross weight of 134,200 pounds but, because of its six axles, the per-axle weight was 25,200 pounds.

That was significantly less than the 33,900-pound axle weight of the John Deere 8230 with 6,000-gallon Husky tank that had a gross weight of 89,600 pounds.

“If the equipment is not set up properly, there’s a dramatic difference in terms of damage,” Erb says. Therefore, it is important to see that the equipment is properly balanced.

The 6,000-gallon Husky tank placed more weight on the rear axle, which increased the pressure on the road and resulted in the second-greatest rutting potential of equipment tested.

The terragator had the highest amount of rutting potential because it places all of its weight on the very narrow lugs while moving on pavement. Third was the properly balanced 6,000-gallon tanker.

The remainder of the equipment was about equal, but all forms of agricultural equipment were found to be more damaging than the 80,000-pound semi-truck.

Distance from edge

The asphalt strain and subgrade damage was reduced by 75 percent if the center of the tire was 16 or more inches away from the edge of the asphalt. Equipment operators can minimize damage by staying farther away from the edge of the road.

Having a paved shoulder also helps, as long as it is not driven on, because this keeps the subgrade from being pushed out from under the edge of the road.

Pavement construction

“The quality of subgrade and asphalt is critical,” Erb says. “Where the contractor skimped us an inch, that’s where we blew it out.”

Seasonal differences

“Seasonally, we know this – spring is bad. We need to keep off of the road when the frost is leaving the subgrade,” Erb says.

It is also important to remain off these roads anytime the subgrade is wet. Townships and cities should look at proper drainage of the subgrade to minimize these occurrences.

Erb says they found less damage occurred in the morning (before 10 to 11 a.m.) than in the afternoon, no matter what time of year it was. Heaviest loads should be hauled early in the day.

Tires

The study revealed that pounds per square inch (PSI) in tires impacts soil compaction but did not significantly impact asphalt or concrete pavement damage.

When two tank trucks, one with radial tires and the other with flotation tires were compared, the radial tires did produce a slightly higher asphalt surface and subgrade strain but not enough to be significant. This difference happened to be greater when the trucks were empty.

Based on data from the study, Erb was able to set up a computer model to determine if one million gallons of water is to be moved, which vehicle would cause the least bit of damage.

On both the five-inch and seven-inch slabs of concrete, pavement fatigue was seen greatest with the terragator, followed by the unbalanced tanker and then the 4,400-gallon straight truck with radial tires. However, there was significantly less damage seen on the thicker pavement.

For both thicknesses of asphalt, not one piece of equipment was dramatically worse than another. However, in terms of subgrade damage, both the 80,000-pound and 102,000-pound semi-trucks were much less damaging.

Results of this study will now be used to determine how to extend the life of rural roads. ( Click here to read about some ideas already taking shape in Lee's article in the March 21st issue of Progressive Dairyman . ) PD

Karen Lee

Midwest Editor

karen@progressivedairy.com