In particular, those dairies that have been working with an IVF program for five years or longer are seeing the investment pay off right now, as they notice more efficient cows that get pregnant more quickly, consume less feed and milk more efficiently.

IVF is the fastest way to optimize genetic potential of a herd. Multiplying a herd’s best genetics and genomic testing only enhances a dairy’s genetic advancement, leading to healthier and more efficient animals even faster. And IVF technology has evolved so significantly we can now work on customizing genetic programs for A2, polled and gender selection strategies.

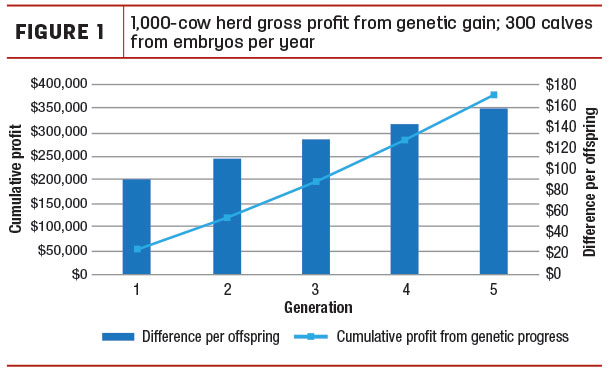

Figure 1 shows the gross profit resulting from the genetic gain of a 1,000-cow herd utilizing an IVF program coupled with genetic testing to identify the donors and recipients.

Generations are represented on the x-axis with profit represented on y-axis, both on a cumulative (left) and per-offspring (right) basis. To have 300 calves born from embryos, a 1,000-head dairy would need to create 700 embryos assuming an approximately 43% live calf rate, which could be done from working a group of five to six donors every two weeks.

Generations are represented on the x-axis with profit represented on y-axis, both on a cumulative (left) and per-offspring (right) basis. To have 300 calves born from embryos, a 1,000-head dairy would need to create 700 embryos assuming an approximately 43% live calf rate, which could be done from working a group of five to six donors every two weeks.

Noticeably, the difference is small initially at only $20 per head but, over time, it’s easy to see where a progressive dairy can take the lead. This gradual but steady increase in an offspring’s dollar value from generation to generation is significant, rising to over $160 per head in generation five, with resulting cumulative profits reaching $350,000. This is the kind of long-term financial impact progressive dairies must keep in mind and put to work in order to survive both today’s volatile market and be profitable well into the future.

An IVF myth that often holds producers back is: It is a difficult, cumbersome process. In reality, it’s quite simple and duplicated easily from coast to coast. The process looks like this:

1. Donors are selected for IVF based on their genetic value.

2. Donors follow a super-ovulation protocol preparing them for the OPU session.

3. Oocytes are harvested by an accredited veterinarian.

4. Oocytes are placed in an incubator and transported overnight to the laboratory.

5. Oocytes are fertilized to create embryos six to seven days later.

6. Recipients are prepared by the client for the embryo transfer following specific synchronization protocols.

7. Embryos are shipped for fresh implant within a 24-hour window or frozen for future use.

Innovations have made IVF simpler, easier and widely available, including:

-

Accessibility: More veterinarians in more locations now offer OPU services. They can send the oocytes collected to IVF labs across the country.

-

Semen costs: Elite genetics have been difficult to access in the past, but most desirable bulls are now available sexed, and IVF labs can work with a sexed product more easily than in the past, giving producers easy access to female-sexed embryos sired by elite bulls.

-

Set up: The IVF set-up process is simpler than conventional flushing with no heat detection or breeding of donors required. Dose and number of FSH injections and coasting periods also create a customizable approach to donor stimulation, allowing each heifer to produce the optimum number and quality of oocytes.

- Donors: IVF allows you to work with donors as young as 6 months, up to 100 days gestation and as frequently as every two weeks, none of which are possible with conventional embryo recovery. Because producers are able to maximize the number of embryos created from top-end donors, they can make genetic progress faster than ever before.

As our industry continues to evolve and adjusts to our new reality following the onset of COVID-19 and its related impact, efficiency is more important than ever. Working with technology, we know our industry will continue to evolve and that our resiliency and tenacity will see us through this time as it has in the past. ![]()

Brenda Lee is a marketing communications specialist with Semex. Email Brenda Lee.

At the time this article was written, Veronika Laskowski was employed as a satellite OPU and customer service coordinator with Boviteq.