Before launching a robotic milking system, you need a carefully considered and well-thought-out plan. This way, regardless of the highs and lows, you will always know that you made the right decision. The preparation lays a solid foundation for the project.

Choosing for the right reasons

In order to choose robotic milking for your business, you have to like cows. Let me explain: Opting for this technology in order to be in the barn as little as possible, to have the machine do the milking for you and eliminate all contact with the animals is not the right reason. Milking contact will be replaced by management contact. It will be different but essential to the project’s success.

You also have to be prepared to handle a certain level of technology, which requires adaptation and a different way of doing things. I often say that, for many people, technological adaptation is easier than economic adaptation. Whatever your future projects may be, it will involve an investment that will have a financial impact on your business. The manager in you will have to prepare for this different way of managing, or you will have to surround yourself with people who are comfortable with managing this type of milking system.

An essential relationship of trust

Frequent meetings with team members must take place before an initial plan is developed and implemented. These meetings will provide the foundation for good communication and help clearly define the business’s goals. A relationship of trust is essential to this type of project because once it is underway and the cows have entered the building, if you are stressed out and tired, this relationship will help calm you down and refocus you on your initial goals.

Preparation, preparation, preparation

As mentioned previously, carrying out this type of project requires tremendous preparation. Several visits will be needed to choose the model that meets your expectations and those of your business partners. Visiting robotic milking operations and asking people questions will likely confuse you even more at first. However, if you and your business partners are familiar with and confident about your corporate goals and values, you will always have an answer when you go back to the drawing board. “Why are we carrying out this project and what are we hoping to achieve? Are we doing it for the right reasons?”

During visits, don’t hesitate to ask owners: “If you had to do it all over again, what would you do differently?” We’re always eager to share our successes but less inclined to say what we could have done differently. It’s great to learn from other people’s successes, but it’s also wise to avoid repeating their failures.

Learn all about robotic milking systems through reading, visits to websites and discussions with other farmers who have robotic operations. Take part in workshops and conferences on the subject.

Once you’ve developed a plan, be prepared to change it. If you haven’t torn it up at least 10 times, it’s still not right. Once again, consultations and communication are key to developing a plan you will be working with for the next 20 to 30 years.

If you choose to take on a new project of this magnitude, you definitely want it to be profitable. It’s important to know that you shouldn’t take the same approach to developing a robotic milking system as you would to building a conventional freestall housing barn. Always keep in mind, voluntary milking is the most important factor in maximizing the profitability of the project. Consequently, everything must be planned and calculated to provide animals with an environment that takes their food intake, bedding and, obviously, milking into account. When it comes time to consider space at the feedbunk, stall width, type of bedding, comfort of walking aisles, ventilation and lighting – everything must be done to maximize production by optimizing feed intake, bedding, rumination, watering and voluntary milking.

Ease of human work must be taken into account to increase operational efficiency. Since each minute counts, you have to keep in mind the goal of constructing a building that allows you to produce more milk per cow per hour, all within the established budget.

Planning for the best - and worst-case scenarios

You will have to prepare for scenarios where the price of milk is lower, or interest rates are higher, while being able to assess your ability to repay based on these different scenarios.

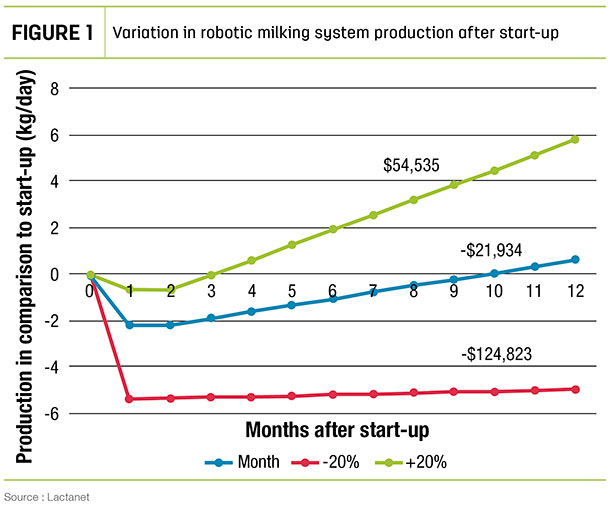

You should also prepare for scenarios involving the purchase of cows or different ration costs per hundredweight – for example, less optimistic scenarios that point out weaker but nevertheless achievable margins. You should also imagine scenarios in which production performance is lower than it is currently, which is expected in the first year. As illustrated in Figure 1, taken from an analysis by Lactanet of 44 farms that switched to robotic milking systems, most recorded production losses that resulted in loss of revenue.

Will it be necessary to assess the opportunity to carry out the project in stages? Maybe. Doing everything at once can significantly jeopardize the business and greatly reduce flexibility. It’s a decision that must be taken as a team. Each person has his or her risk tolerance when it comes to debt, but the reality is: You have to make those payments at some point. Make sure you do not lose your joy of work because of heavy financial pressures.

Conclusion

You always have to remember: The first year is a year of learning for both the cows and the owners. Even when you’re surrounded by experienced people, every robotic milking system start-up is unique.

When your economic and technical performance scenarios show figures you are OK with, the project is most likely to be successful. Obviously, these scenarios have to be realistic, understood and approved by the entire team involved in the project because each team member will have a role to play when the time comes and will be an important factor in achieving your goals.

This type of project is stimulating – it will sometimes raise doubts and cause you to question yourself, but always with a vision of creating a company in your mind that will meet your goals and allow you to grow according to your expectations and needs.

Lastly, you can count on your agricultural adviser who is well equipped to help in regard to either economic or feeding scenarios – they will be an important asset in helping you better prepare for working with your financial adviser and other team members. ![]()

PHOTO 1: Marc-Étienne from HLR Faucher Farm in Saint-Ludger, Quebec, with Yvan Rosa, consultant with la Coop Alliance, discussing their robotic milking transition plan.

PHOTO 2: Transitioning into robotics is not a little job – it requires your project to have been seriously studied and planned. Keep in mind that the objective of a new build is to allow you to produce the most milk per cow per hour while respecting your budget.

PHOTO 3: You always have to remember: The first year is a year of learning for both the cows and the owners. Photos courtesy of Sollio Agriculture.

-

Philippe Couture

- Specialized Adviser, Robotics

- Sollio Agriculture

- Email Philippe Couture