During challenging times, dairy producers are thinking about ways to improve their situation and maximize the benefits of the investments already in place, like long-day lighting (LDL) systems. While known to boost milk production, some dairy producers may not realize the payback on LDL only happens with proper timing of lights and recommended management for both lactating and dry cows.

Whether you have an LDL system in place or are thinking about adding it to a new or existing building, consider these three concepts that might help further improve cow productivity and health, as well as the bottom line:

1. Your LDL system may no longer be delivering the expected extra milk production. Troubleshooting the system and adjusting some herd management routines may restore the profitability of this technique, adding a net profit of up to $100 per cow per year.

2. Combining effective heat abatement for dry cows with resetting cows for maximum response to LDL can set your cows up for improved health and higher production, lasting for three cow generations. Heat stress is a much more serious problem for dry cows than previously understood. Research at the University of Florida shows cows exposed to heat stress during their dry period experience health problems and a considerable loss of milk production in the following lactation. In addition, the future milk production of their daughters and granddaughters is substantially reduced. (Combining effective cooling and true short-day lighting for dry cows will be explored in an article to follow.)

3. Long-day lighting isn’t for lactating cows alone. Practiced with replacement heifers, it can bring about faster, leaner growth, earlier breeding and calving ages, and higher future milk production. Whether this technique is feasible and economical for a heifer-raising program depends on your housing and herd management routines. (This opportunity will be highlighted in a separate article to follow.)

Are you leaving money on the table?

Long-day lighting is a herd management technique capable of stimulating cows to produce about 5 pounds more milk per day. Like other herd management actions intended to increase milk production per cow, LDL helps improve cow productivity by increasing the marginal feed efficiency. Let’s look at the following example:

- A Holstein cow producing 80 pounds of milk consumes 50 pounds of dry matter (DM). This represents an overall feed efficiency of 1.6 pounds of milk per pound of DM.

- Stimulated by LDL, this cow produces 85 pounds of milk and consumes 51.5 pounds of DM. This raises the overall feed efficiency to 1.65 pounds of milk per pound of DM.

- The cow produces the extra 5 pounds of milk, using only 1.5 pounds of DM. This means the marginal feed efficiency is twice as high as before, or 3.3 pounds of milk per pound of DM.

The increased feed efficiency is the reason why LDL can generate a net profit of up to $100 per cow per year, even if milk prices are low. However, to achieve this, you need to follow the rules for this management practice. If not, you may be leaving money on the table.

It is worth pointing out that increasing production per cow, as a result of practicing LDL, does not necessarily increase the herd’s total production. In a situation with quota, or a contract limiting the amount to be received by the processor, the milk production increase can be balanced by earlier culling of inefficient cows in late production or those with high cell count or health challenges.

Does your long-day lighting really work?

Once an investment in a lighting system designed for LDL has been made, it’s important to know that you will continue to get a good return on the investment. When starting to use LDL, the initial production response may have been noticed. Over time, herd management routines, pen/barn assignments and other things may have changed, such that your operation is no longer meeting all requirements for effective LDL. For example, circumstances may have required dry cows to be housed in the same barn as lactating cows. If so, a production response to LDL cannot be expected in the following lactation.

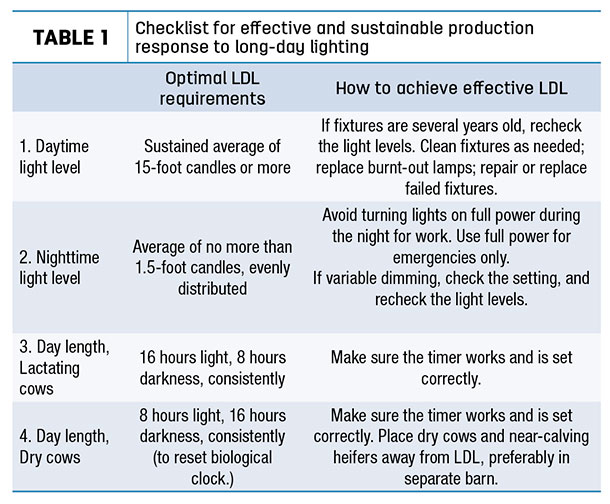

With so many things potentially impacting the daily milk tank reading, it is hard to tell to what degree the LDL practice is still working. Use the checklist (Figure 1) below to diagnose and troubleshoot your LDL system. If all four items earn a checkmark, you can expect cows to respond fully, whether you already practice LDL or are making plans for a new barn. The first three rules are fairly straightforward. Rule number four deserves some more discussion.

Making adjustments as needed, such that all requirements for effective LDL are met, represents a potential improvement to your bottom line of about $100 per cow per year.

Resetting the biological clock

Long-day lighting is a well-researched herd management technique for lactating cows. After experiencing long days during their lactation, cows need to reset their system in order to be able to respond again to long days in the following lactation. Under natural lighting, cows experience cycles of annual variation between short days in the winter and long days in the summer. When using the LDL technique, cows need to experience similar cyclical changes between long days during lactation and short days during the dry period. This is consistent with how the ancient cattle experienced seasonal change. Their long dry period during the winter had short days, and during their lactation period, they experienced long summer days.

Most LDL systems have been designed with the recommendation that dry cows and near-calving heifers be housed away from the lactating cows, such that they can experience natural day length. This arrangement provides truly short days only in the middle of the winter. At summer solstice, dry cows in the northern U.S. experience no change when going from 16 hours of LDL during lactation to 16-hour natural day length at dry-off. Without specific research studies to draw on, we can assume that between spring and fall equinox, dry cows will not be fully reset and are likely to have a reduced response to LDL in the following lactation.

In order to provide a full-strength reset year-round, dry cows would need to be housed in a separate, enclosed barn where artificial light can create a consistent day length with eight hours of light and 16 hours of darkness. Such enclosed barns would need to provide effective cooling to prevent heat stress and would be expensive to build. However, if we consider the combined health and production benefits as a result of a complete reset for LDL and preventing heat stress, this type of investment may be profitable.

Planning for a new lighting system?

LED technology is constantly evolving and reaching higher levels of energy efficiency (lumens/watt), but the electrical bill considers the performance of the lighting system as a whole. If you seek professional help, a smart design for effective LDL can provide up to 30 percent of additional energy savings. Fixtures and lighting controls should be designed for dairy barn and parlor environments, preferably with a rating of IP67 or better. Dimming capability is critical when selecting fixtures for long-day and short-day lighting installations. Operate all fixtures dimmed down low to get the best nighttime lighting. Fixtures need to be capable of dimming down to 5 percent of full effect and operate without flicker at these low levels.

Recommendations

To determine the effectiveness of your LDL system, compare your current management practices to the checklist. If the hardware is in good condition, revamping the system can be very profitable. If you are planning for a new lighting system with LDL, consider seeking qualified help to get it right the first time. ![]()

Gunnar Josefsson is a consultant with Dairy Lighting Solutions LLC. Email Gunnar Josefsson.