With summer and hay season already upon us, it’s too late for most producers to consider going through their balers with a fine-toothed comb, which is best done during off-season servicing.

However, there is still much that can be done during the season to help decrease any potential downtime and reduce stress during those long days when the conditions are right and it is the prime time to harvest the crop.

Inventory check

Nothing is more frustrating than a shear bolt or a ball of twine standing between you and having the hay up before the weather turns. Generally, these parts are readily available at a local dealer or store, but that delay can be costly and stressful. Therefore, being sure what supplies you have in stock on the farm is recommended.

Ideally, it’s great to have at least two of every shear bolt for the machine, extra balls of twine/rolls of net wrap, extra preservative and a basic tool set. Each of these supplies should be available in the field to quickly address any simple issues that may arise.

All of these items will store without losing quality (if stored properly) and would be needed for the next cutting or season, so it makes sense to have them on hand, especially if it can save you precious time.

Daily check

Be sure to check the machine prior to heading out for the day’s work. If there is a lot of crop accumulation, it is a good idea to clear the crop from the machine. This helps to expose any issues that would otherwise be hidden on the machine, allowing them to be addressed right at the shop.

If the machine is equipped with automatic lubrication systems or remote grease fittings, keep an eye out for ruptured lines that are not delivering any grease to the fitting. Also look for any oil seeping out of gearboxes and check any fluid levels that have a sight glass or dipstick.

Now is the time to grease any fittings that require manual greasing and lubricate any chains that are dry. (Consider lubing the chains when warm from use if possible.)

Be aware of the intervals the manufacturer specifies – it is possible to over-grease components and cause premature failure or cause a part to not perform as designed. With automatic lubrication systems, check the reservoir level and top it off if necessary.

If the baler is equipped with a cutting system, be sure the knives are sharp. A dull knife will increase fuel usage and power requirements – not to mention it will increase wear and stress on the cutting system. In extreme conditions, it may be necessary to sharpen the knives more than once per day.

A second set of knives can prove very useful in such situations, as the dull set of knives could be swapped for the sharp set with minimal downtime.

Finally, you should ensure there is sufficient twine and preservative for the day’s work, the road lights are functional, and the baler is securely hitched to a fully fueled tractor. It would also be a good idea to run the machine up to operating speed, check all hydraulic functions if possible, listen for any abnormal sounds, check belt tracking (round balers) and make sure no errors come up on the machine controller.

Between cuttings

Once all the hay for the cutting is successfully baled and stored, it’s a good time to make sure the little things that reduce functionality but still let you run the machine are taken care of. These issues should be recorded when they occur during the baling.

This way, the later issues can be addressed immediately and not forgotten about until the baler is needed later on in the season. Maintaining a record of performed maintenance is extremely useful.

Check drive-shaft joints, clutches and freewheel bearings for tightness and proper functioning. For a large square baler, make sure to check the play in the plunger rollers and shim the rails as needed.

Plunger alignment is also good to check, but most operations won’t need to do this more than once a year. The plunger knives and scrapers should be checked for proper alignment, clearance and sharp edges. This is also a good time to replace any broken or bent pickup tines and work to straighten any pickup bands that are out of place.

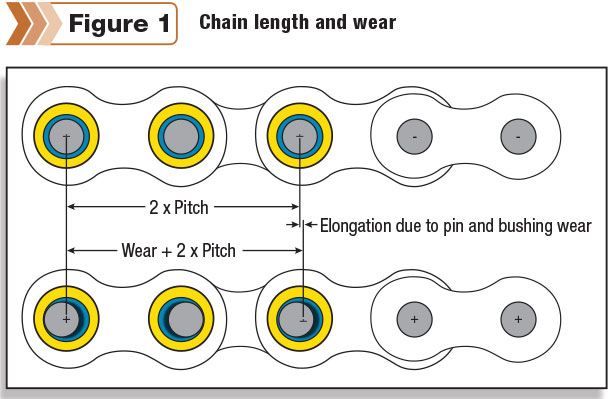

Check chains and sprockets for wear. Chains should be checked for elongation due to wear. In addition, the chain tension should be checked to ensure there is no irregular wear due to poor alignment or contact with obstructions. A chain should be replaced if the elongation is equal to or greater than 3 percent.

A chain that is beyond this industry standard will cause the sprockets to wear out much more quickly than they would if the chain was kept in good condition. Figure 1 can be used to understand how to check this important component for wear on the machine.

There is a lot of work and planning required to have a smooth and successful harvest with any crop. Make sure that neither the machine maintenance nor the availability of supplies is overlooked and you will reduce the stress associated with the long days of harvest.

Be sure to check inventory and the operator’s manual for proper setup and maintenance schedules so you are ready for the next cutting. PD

PHOTO: A baler picks up hay and produces a large square bale. Photo provided by Marcus Cernek.

Marcus Cernek is a technical support specialist with Kuhn North America.