Three dairy building contractors provided Progressive Dairyman with an across-the-country cross-section of trends in their respective regions.

Panelists

Midwest: Duane Ambrosius, agriculture sales manager/consulting specialist, Bayland Buildings Inc., Green Bay, Wisconsin

Northeast: Don Richards, owner, Complete Construction Concepts LLC, Homer, New York (former office of Fingerlakes Construction)

West: Michael Bingham, project manager, Westec Inc., Jerome, Idaho

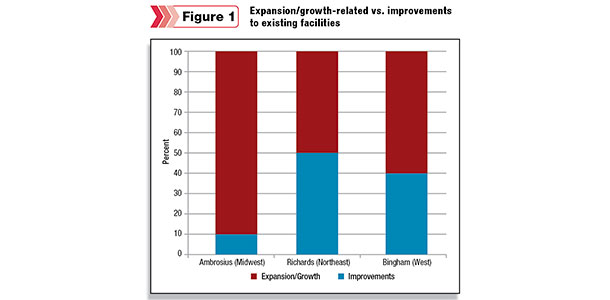

Compare and contrast the type of construction you are seeing. What percent do you estimate is expansion/growth-related vs. improvements to existing facilities? (Figure 1)

Ambrosius: I would say 90 percent of the projects we are working on are expansion-related or growth-related, but when talking to producers in general, I would say the ratio is 75 percent expansion/growth and 25 percent improvements such as updating stalls and headlocks, updating manure systems, re-roofs, etc.

Richards: This year, I would say it is about 50-50. We’ve done a lot of work expanding and revising facilities.

Bingham: We are seeing some of both, about 60 percent related to expansion and 40 percent improvements to existing facilities.

Are you seeing more, less or the same number of building projects now compared to the last five-year average?

Ambrosius: 2007 and 2008 were the strongest years in construction for our agriculture division. This year, we are seeing construction at 30 percent more than in 2007 and 2008. When averaging the last five years to the current year, we are constructing approximately 60 percent more.

Richards: We are seeing about the same. In some of the past years, we built whole new complexes, but we saw none of those this year. People are either adding on to existing or remodeling.

I think a lot of local guys we work with have put in new milking centers and are now bringing cow numbers up. Their parlor may be only five to six years old, and now they are making room for expansion to milk more cows. There is some chatter here for growth for next year.

Bingham: We are seeing more projects this year. By and large, more interest in building, as well as fixing things up to repair and bring facilities into better condition.

How would you describe the interest in robotic technology (milking systems, calf feeders, etc.) in your area?

Ambrosius: Our area had been lagging when it comes to robotic technology. In the last two years, the robotic interest in milking systems and calf feeding has exploded and taken off. Milking robotics is playing a big role in mid-size farms today. Robotic calf-feeding systems are playing a big role in the large-scale dairy facilities due to easier management of calf numbers.

Richards: We have talked to some people about robotics, with the most interest in milking systems. We have done one robotic project.

Bingham: We have had some interest, particularly among smaller dairymen (around 500 cows or less). There have been some automated calf feeders in the area for a while. On the milking side, there is interest there, but on what scale, I don’t know yet.

As bigger rotary parlors are in place, larger producers may look into that. It depends on what happens with the labor market. If it makes sense dollar-wise, I think people will look at it.

What trends do you see in construction preferences?

Ambrosius: The trends today that we are seeing are that farmers are focusing on quality and efficiency. A couple years back, when the economy was at a low point, operators were pinching pennies and focusing on price.

Richards: The biggest thing we talk about is cow comfort, including the width of scrape and feed alleys. Increasing number of crossovers for waterers to make them more readily available seems to be something dairymen are concerned with.

The other trend we are seeing is to get heifers acclimated to freestalls as soon as possible. We used to do more pack buildings for heifers coming out of hutches. Now, more people are trying to get them right into the freestalls.

Bingham: I do see more people interested in cow comfort. We have put in feed-line misters and cooling systems in parlors for cow comfort. More clients are interested in mats for floors in holding pens or on the cow deck.

When they make these improvements, they can see the difference. The same goes for fans. We are looking at different things to help increase milk production as well as reproduction and cow health.

What factors do you think drive these trends?

Ambrosius: The main factors are definitely the economy and the future outlook of the economy.

Richards: The trend for more cow comfort is driven by production. With more comfort comes more production. As far as the heifer trends, people want the heifers to be trained in how to use freestalls from an early age so they are better prepared for the production stage. It is easier to train them at a younger age.

Bingham: When it comes to cow comfort, dairy producers see that when they put money into that, it is not money thrown away. There is a return. With those types of things, they see that they can get money back because they are helping the cow. Maybe she lives longer, has better reproduction and better or steadier milk production. Technology helps with that too, as more people are tracking that information.

What words of advice do you have for dairy producers considering a building project

for 2015?

Ambrosius: Start to look ahead at your future projects sooner than later. The demand is extremely high for agriculture construction in 2015. To be able to meet your deadlines, you should start to talk to your construction consultant now.

Richards: Start early. As we get into the busy season, it is hard to meet everybody’s demands. It is always more cost-effective to book a project early. Though it is hard to predict, right now, it looks like the cost of materials will be about the same.

It doesn’t look like huge increases on the wood or steel side, which is another reason to book early and get materials committed to your project. We don’t usually see increases in concrete pricing until after April 1.

Bingham: Plan ahead. Spend time on the drawing table and plan. Do your homework, know what you want, and go around and look at facilities. If you do that, you will be money ahead. As far as materials, they are trending up, but out here the cost of labor is typically increasing at a faster rate. PD

Peggy Coffeen

Editor

Progressive Dairyman