Change can be a good thing, especially when it is followed by positive results like increased milk production, reduced culling and longer productive life. Nehls Brothers Dairy, a 1,900-cow operation owned by Greg and Royce Nehls located near Juneau, Wisconsin, is reaping the rewards of a series of cow-comfort improvements including stall renovations, sand bedding and improved footing.

Call him the ‘cow whisperer’

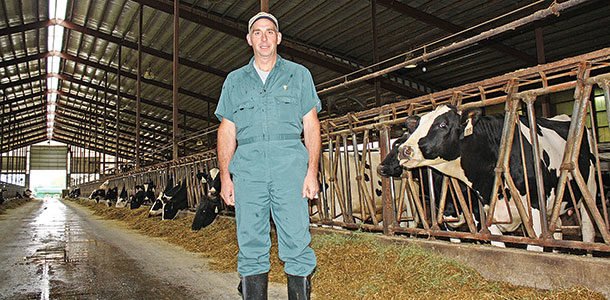

As a veterinarian by training and a dairy cow campaigner by nature, Jerry Gaska, DVM, the farm’s dairy manager, believes his job is to represent the bovines’ best interests when he sits down at the table to make management decisions.

“I speak for the cow,” he states. “I have always thought of my role as the voice of the cow. I really see the value in how cow comfort helps performance and health, and I have been an advocate for bringing that perspective into how decisions are made on the dairy.”

When cows talk to Gaska, he listens. In fact, one such conversation prompted an overhaul of the fresh cow pen.

“These nice, big-framed cows were looking at me saying, ‘I want to lay down, but I can’t fit in that stall,’” Gaska recalls.

The undersized stalls, measuring 46 by 90 inches, were actually deterring larger cows from lying down. Because it was difficult to fit in the stall and even more challenging to stand up, these cows were favoring standing over relaxing. The conversion to deep-bedded sand and larger, more comfortable stalls has made a “night-and-day difference.”

“It was a dramatic improvement, as far as lying times,” Gaska says, noting that his strolls through the fresh pen are much more pleasing as he sees cows comfortably resting instead of standing.

Fresh cows now enjoy wider, longer 50-by-96-inch stalls filled with 10.5 inches of deep sand. The sloped concrete brisket in the front of the stall encourages cows to stretch out a front leg, a natural position Gaska likes to see. He also notices a difference in fresh cow health, demonstrated by lower cull rates and a higher transition cow index (TCI) score.

The switch to sand

While the conversion to deep sand beds in high-priority areas like the fresh cow and fresh heifer pens and the hospital pen is more recent, Nehls Brothers Dairy made the switch from mattresses and sawdust to recycled sand beds about four years ago.

“We are absolutely convinced that the move to sand was the right move,” Gaska states. “We gained a fair bit of cow comfort as far as lying time and reduced hock injuries with going to sand.”

He admits that at first, working with recycled sand presented a learning curve; however, today he feels comfortable with the dryness and cleanliness of the sand they are producing.

The dairy’s sand separation system was modified to pre-clean the sand, and a shaker box was added to remove excess moisture for better drydown. They are able to keep additional bedding costs to a minimum, only purchasing one truckload of new sand every two weeks.

Part of Gaska’s fine-tuning for cleaner, drier sand included experimenting with different types of the material.

“Not all sand is created equal,” he advises. “What’s great for the drying system may not be great for the cows. You have to find something that works for both.”

For his particular system, Gaska prefers a rounder-grained river-bottom sand. This sand tends to contain smoother particles than coarser, more angular sand that may come from other sources. In his experience, sand that is too coarse can lead to foot problems.

Happy feet

Gaska sees hoof health as a top priority; thus, improving footing is another key area he has been involved with at Nehls Brothers Dairy.

“The addition of rubber on all of the cow traffic surfaces outside of the pens has been a big win for us,” he notes. “It has helped tremendously to decrease wear on the cows’ feet and improved comfort in areas where they stand.”

Prior to lining the breezeway, alleys, return alleys, holding pen and milking parlor with rubber, cows were suffering hoof insults due to rough and abrasive concrete. Now, lined wall-to-wall with rubber, there is no exposure to the hazardous surface. He recalls, “We had some pretty bad concrete under those cows. For us, the difference has been dramatic.”

Gaska particularly notices a difference in the mobility and hoof health of young cows that were not exposed to the previous concrete surface compared to older cows that once walked on it as part of their daily routine.

“Lameness is a lifetime disease,” he adds. “Cows that came through the system then still struggle with lameness.”

With these combined efforts, Gaska feels confident that the improvements the dairy has made over the past few years position them for continued success, and he is committed to keeping the cows’ best interests at the forefront.

“We are addressing issues like lameness and animal welfare in a very positive way,” he says. “Our goal is to provide the best environment for the cows.” PD

Photos by Peggy Coffeen.

Peggy Coffeen

Editor

Progressive Dairyman

Key priorities for cow comfort at Nehls Brothers Dairy

At Nehls Brothers Dairy, Jerry Gaska, DVM, manages the cows by keeping their best interest in mind. He concentrates on these areas for optimal cow comfort:

- Keep cows clean, dry and comfortable

- Maximize lying time

- Minimize time spent in lockups or standing (when cows cannot freely eat or drink)

- Provide good footing for hoof health

- Design and maintain stalls for optimum comfort