Look at their position, complexion, vital visual signs; get close and listen for air flow and breathing; and feel for a pulse which assures blood flow. These are the critical ABCs for life (air, breathing and cardio).

These same words are critical and are the basis for assessment and health of your milking equipment and routines. They can be a lifesaver and are often the difference between profitability and problems, as proper air flow and milk flow are as vital to milking equipment as air and blood flow is to humans. Also, by using these senses (look, listen and feel) on a daily or routine basis, you can avoid those milking equipment traumas before they happen.

Air versus fluid flow

While both air and fluid are very important for life and milking equipment, and they need to work together, prioritizing and focusing on the most important is critical. In humans, fluid or blood flow is most critical. Having a strong heart and great blood vessel system is paramount for good lungs, air function and movement.

Then lungs provide oxygen, which the blood carries to everywhere needed. In milking systems, creating proper air flow or vacuum (negative air pressure by removing air), distributing that vacuum where needed (like blood vessels), regulating that vacuum (like blood pressure) and letting planned air in to change vacuum (pulsators for proper teat massage and air bleed holes in claws or inflation to effectively move milk from cow to milkline) is most critical. If this is done properly, system parts are sized correctly, and the cow is stimulated properly, milk will flow on its own.

To ensure the milk can flow, your harvesting equipment must be working at top-notch every milking of every day. Here are some simple daily routines where you look, listen and feel to make that happen.

LOOK!

(Use your eyes to assess vital components and signs, including milk flow)

- Look daily at all the rubber parts (inflations – the only part that milks, massages and touches the cow; and short milk tubes – proper air movement from pulsator to massage teats). Are they worn out, cracked, kinked, twisted or dirty? Are you changing inflations when recommended? These are working and moving every minute your machine milks. Weaknesses here are bad, just like leaky or clogged blood vessels.

- Look at your milk hoses without and with milk flow. If Tygon or silicon, can you still see through them, or are they cloudy, dirty and stretched? It may be time for new vessels. Also, does milk flow quickly through or seem slow (evidence of a blocked air bleed in claws or inflations)?

- Look at your regulator (brain of the system that calculates and regulates air getting in to keep vacuum constant). When was the last time you cleaned the air filter?

- Look at your vacuum gauge. This is like your blood pressure reading. When the system is off, does the gauge read zero (proper baseline)? When milking, is the vacuum at the same level every day and through milking? Is the reading constant or is it fluctuating? When you let air in when putting milker units on, does it drop? Does it always go up quickly to the same level? Unlike your blood pressure, this should be constant, no matter what stress is on the system.

- Look at your vacuum pump occasionally, even though it is usually hidden somewhere. Is it clean or dirty and oily around it? If it is belt-driven, is the belt tight? More than a quarter-inch play on the belt can reduce the pump’s capacity immensely.

- Look at all those vacuum lines (big PVC air vessels) occasionally. Any signs of leaks, cracks, sagging or breaks?

- Now it’s time to milk, so look at those teat ends. Make sure they’re healthy, disinfected, clean and dry before putting milker units on. See if they are plumb full of milk to show there is proper stimulation happening.

- Finally, look to see that milk gushes into the claw continuously (not dribbling or bimodal), again evidence of good udder prep and proper equipment.

LISTEN!

(Looks can be deceiving, so use your ears to assess proper air flow)

- Listen to air bleeding into air vents in your claws and shells. No noise means slow, poor milkout.

- Listen to your pulsators. Better yet, take off an air hose (short milk tubes) and listen to the intermittent air bursts. They should be loud and crisp and all units the same. This is evidence the inflation is opening (milk) as well as closing (massage). This is critical for teat health.

- Listen to your regulator. If you don’t have a variable-speed drive, the regulator should be letting in a lot of air. As your air insurance policy, it is balancing the equation of what air the vacuum pump is taking out, what air is coming in (air bleeds and pulsators [good air] as well as excess air admissions when applying milker units [bad air]) and then making up the difference to maintain stable vacuum.

- Listen for irregular air sounds (leaks, cracks, torn inflations, etc.). This is detrimental to equipment and cow health. Don’t forget, maintain less than 1% squawking teat cups, or it increases mastitis potential.

FEEL!

(Use your fingers to assess proper unit function)

- Feel (put your finger) on air bleed holes on inflations and claw. You should feel the suction.

- Feel (put four fingers) in the inflations of each unit. This is like feeling your pulse, which is critical to check if you’re alive. If you can’t feel anything, your milking equipment isn’t alive either. Do all inflations and massage action feel similar? Different? This tells vitals about inflations and pulsation functions (twisted, leaks, proper massage, etc.)

Look, listen and feel to check milking equipment daily. These are simple, life-saving measures for your milking equipment. At the same time, don’t forget two other very important factors to optimize milking: the cow and the machine.

1. Cow: Remember, the milking machine allows milk to flow to lower pressure or vacuum. The other most important and crucial part is proper stimulation, letdown and timing of unit attachment to maximize the cow’s milk pressure in pushing milk into the system. An excellent milking machine can never properly and completely harvest the milk crop without cow cooperation (and the milker, who needs to be trained to achieve this).

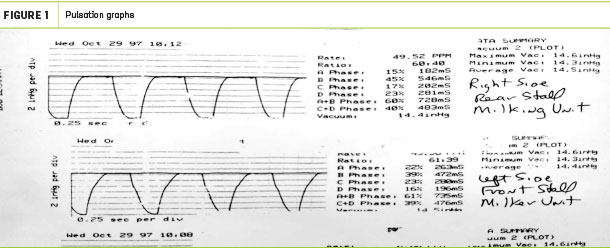

2. Milking equipment checkup and physical by a trained dealer or service person (annual or more often). Your senses work great on a daily basis, but special equipment and tests are necessary to assure proper function (like you can feel your pulse but might need an EKG to assure your heart is working). All pulsators should be graphed to make sure they are functioning properly. Vacuum pump capacity, air flow and leaks as well as regulator function should be tested. The final test is a “stress test” to graph vacuum at the teat end or claw when cows are milking (Figure 1).

Click here or on the image above to view it at full size in a new window.

Can your milking system handle the milk flow of your excellent cows? Similar tests are used to check your heart and vessels for blockages or poor flow. These are very critical.

Look, listen and feel are critical steps in life-saving for humans and assessing milking equipment. Don’t wait until after the trauma occurs. The majority of a dairy’s income is not seen until the crop is harvested properly. Certainly, attention to cows and people are critical, but milking equipment is the harvesting machine. Use your senses and these simple tools on a routine basis to assure healthy milking practices and equipment. Your cows and your livelihood depend on it. ![]()

-

Leo Timms

- Morrill Professor

- Iowa State University

- Email Leo Timms