Editor’s note: The following is the first of a two-part article series regarding diesel fuel injection systems. Throughout the past few months, you have read about the history of diesel engines, Tier 4 emissions standards and the SCR and EGR engines. In this column, I’d like to return to electronic fuel controls, more specifically – diesel fuel injection systems. To start off, I’d like to discuss a few points regarding the history of the electronically-controlled fuel injection systems. Somewhere in the late ’70s, manufacturers started noticing that emissions standards were starting to increase at a strong rate.

However, this emissions standards trend started with automobiles first though.

The first stage of these emissions standards was only the beginning of what was to come. These standards continued through the ’90s, where they started to impact diesel engines.

Some of the first changes to the injection system that emerged from these standards were changes to cam timing as well as changes in hydraulic controls to change injection timing. All in all, electronics were taking a turn for the better. At that point, the EPA emissions standards had been met.

Since then though, additional standards have been created that are aimed at obtaining better fuel economies, better engine performance and a reduction in emissions. All of these standards driven by the EPA were placed on the manufacturer, so the manufacturer’s only choice was to step up and create a solution.

I think that electronics overall have given us a new horizon on what we are able to accomplish in terms of engine efficiency, fuel economy and emissions reduction.

Manufacturers knew that changing the injection timing, changing the fuel delivery and lowering the combustion chamber temperatures would create some benefits. These changes ultimately helped reduce emissions.

As the standards evolved, so did the electronic systems. A basic explanation is that the electronic fuel injection system’s “computer” monitors the external atmospheric pressures (altitude) and any changes to these pressures.

The computer can monitor the fuel injection timing as well. The pressures at which the fuel was injected into the engine’s cylinders could also be increased. The fuel could now be atomized and injected into cylinders at really high injection pressures so that the fuel atomized and mixed with the air.

The fuel injection computer also monitors every cylinder that fires off. Every time combustion occurs in each cylinder, it puts out a spurt of energy.

The basic combustion cycle with electronically-controlled fuel injection engines is summarized in the following paragraph.

Air is introduced into the cylinder, which moves the piston down. The valves close as the piston starts moving up, which compresses the air within the cylinder. The fuel is then precisely injected at a high pressure.

The fuel and air mixture is ignited, causing an explosion that drives the piston back down. When it comes back up, the exhaust valve opens, letting the exhaust from the combustion out.

The individual combustions are actually monitored through crankshaft sensors, camshaft sensors or additional sensors, wherever they may be. Some engines even have them in the fuel injection pumps.

An advantage of electronic fuel injection is that these sensors monitor the combustion cycle within each cylinder. If the power stroke in one cylinder is just a little bit smaller, the injector system could compensate for that in the next cycle, using a little bit more fuel.

So, for example, if you’ve got a six-cylinder engine, each individual cylinder is being monitored, analyzing your engine and how it runs.

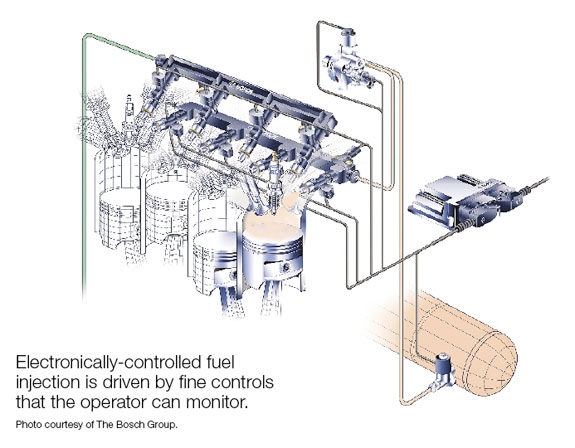

In conclusion, I think it’s important to point out that all this technology is now available to us. Electronically-controlled fuel injection is driven by fine controls that the operator can monitor.

And to think we used to only get four to five miles to one gallon! I think vehicles today get a bit more than that. PD

PHOTO

Electronically-controlled fuel injection is driven by fine controls that the operator can monitor. Photo courtesy of The Bosch Group.