“If they positioned the dipstick under a cow’s tail on a loader, then maybe the herdsman and his helpers would check the oil.” I asked a dairyman what his pet peeve was pertaining to mechanical things at his dairy. The above quote was his first response. He went on to say that if a person can’t handle gates and free-stalls being mangled by loader buckets without having a meltdown, then maybe they shouldn’t be in the dairy business.

Let’s face it; if a person looking for a job at a dairy had the skills to operate a loader at the journeyman level, he would not be looking for work at your dairy. Most people who want to work can be taught to do more than they have in the past. If they arrived driving a car, there is hope they can operate a motor-driven piece of machinery – with some instruction. That instruction must include his or her responsibilities as to the health of the machine they will be operating.

If your dairy has a shop or a mechanic, all personnel need to understand what their responsibility is and is not. Who checks the oil? Who fuels the machine? Who gives it a bath, and how often? Who greases it, and how often?

A loader with one regular operator and one regular job about the dairy is more likely to be maintained. Part of qualifying the operator to run this loader will be showing him or her where to check not just the engine oil, but all fluids. This person will have no one else to blame if the assigned machine shows up in distress because it ran out of fuel or oil.

One solution for a loader that everybody uses is to assign one crew member to check that machine when he gets to work and make sure it has oil and fuel in it. This same person should also have a schedule for giving it a bath. It’s hard to see a pin about to fall out or a crack in the frame if that part of the loader is covered with manure.

Whoever gets this assignment should be required to keep a daily log of oil added, when it was greased, washed, fueled, etc. If it didn’t get recorded, it didn’t get done.

Remember, this is the loader that after everybody uses it “just for a minute” will show up with a seized engine because “nobody” and “everybody else” was checking the oil.

There’s an old story where a fellow approaches a loader with a grease gun. The loader ran and hid; it had never seen a grease gun before and was afraid of it.

Machinery that works outside in the dirt, manure, silage and hay will get all of those materials inside all the working parts. Air filters, oil filters and grease seals keep most of it separate from the innards of the machine. That’s why the oil inside an engine needs to be changed every now and again. (See the operator’s manual for each machine.) The oil eventually becomes contaminated, and if not changed, no matter how good an oil filter, it will eventually become a cutting compound due to abrasive foreign matter smaller than what the oil filter can remove.

Parts that move outside the engine and transmission will have a means of lubrication. For example, a joint on the linkage between the frame of the loader and the loader bucket will have a grease zerk. Through this, new (and hopefully clean) grease will be pumped into the bearing surface, which moves as the loader bucket articulates. The grease gets between the metal of the turning parts that move in the joint, so there is metal-to-grease instead of metal-to-metal activity as the loader operates.

Grease worms get the blame when something breaks or needs to be replaced because of a lack of grease. Grease worms live everywhere. They are thicker anywhere it is wet, anywhere it is dusty and anywhere there is manure, silage or mud. They are tiny and invisible. They get into the smallest spaces and eat all the grease they find.

There is no poison that will kill grease worms. There is nothing that will repel them. There is nothing that will slow their growth.

The only defense there is for grease worms is to keep them well-fed. Note that grease worms prefer the cheap or bargain grease.

Your oil supplier should be able to provide a lubricating grease that will do better in specific locations than the bargain product. If you have an application that the grease worms seem to clean out quickly, your supplier may have a product that will stay put in that application.

Smear a little of a trial grease on your hand. If you can wipe all traces of it off with a good paper towel, the grease worms will love it. If, on the other end of the spectrum, you have to resort to soap and hot water to get all traces of it off of your hands, then the grease worms will have a tougher time eating it. PD

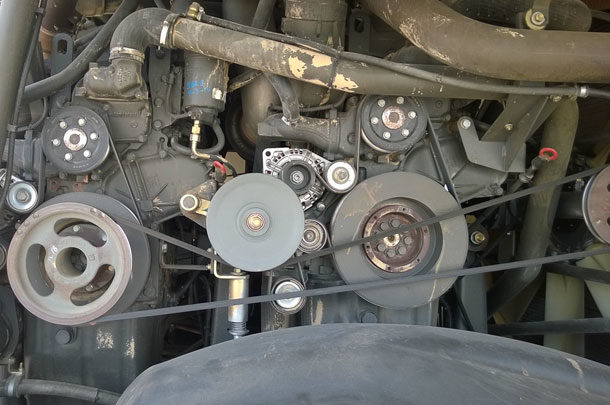

PHOTO: Grease worms also get inside engines and consume the engine oil. Most manufacturers paint the dipsticks a contrasting color, usually yellow or red. Note the two red-handled dipsticks on the twin engines of the chopper in the picture. Photo by Brad Nelson.