Robotic batch milking, designed for up to 1,200-cow modules, was developed to solve issues identified in free-flow and guided-flow automated milking systems. It is a concept where all the advantages of conventional milking are integrated and enhanced with the benefits of automated milking.

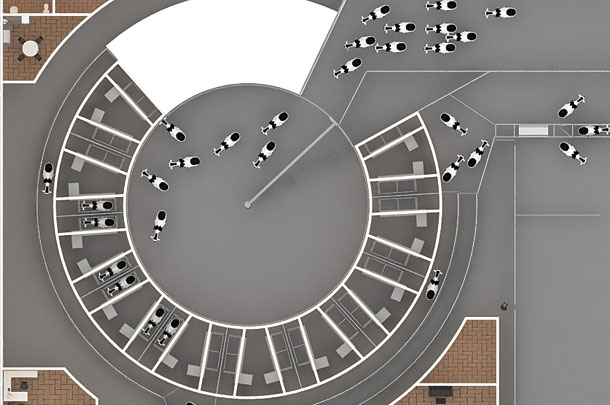

With this design, individual or box-style robotic milking units are positioned around a central holding area in a milking facility located adjacent to cattle housing.

Labor requirements

The human intervention in milking only takes five to 10 minutes when one person brings the complete group into the holding area, with no skills required. This individual can bring 80 to 160 cows every hour to the holding area during a six-hour shift, and the job is done. A second unskilled person can bring the next shift. Both persons will have 45 minutes available every hour to perform other tasks as needed.

A third person can use those 45 minutes per group to perform reproductive or health tasks in the sort pens near the milking area. In this way, when milking is done, the insemination, treatments, etc., will also be done at the same time.

Since all cows are brought to the robots as a batch, there is no need to look for (or fetch) individual cows that did not enter the robots voluntarily.

A crowd gate ushers cows to enter any of the robots’ gates. Social stress is reduced when they are kept together with the rest of the cows before entering the milking system.

Once there, the whole milking process is totally human-free from teat cleaning, stimulation and attachment to milking, cup removal and post-dip.

Data collection

Cows are milked gently while, simultaneously, all the proper sensors obtain data to manage health, reproduction, as well as to provide relevant information for precision management and feed efficiency. Information is collected for each cow related to blood in milk, milk conductivity, milk flow and milk efficiency, production weight, production ratio, protein, fat, lactose, cow activity and rest time.

Individualized feeding

With our system, there is the option to feed cows in the automated milking unit with up to three different components. This allows producers to offer individualized ration ingredients above what is offered at the feedbunk.

Treatment pens

As mentioned, this design allows for insemination and treatments to be done during each milking shift. After exiting the robot into a return lane, cows can be sorted via a three-way sort gate with bodyweight platform to a reproductive area, normal exit or health checking and treatment area. This can be done during one or more milking shifts depending on the farm’s management style.

Once cared for, cows are ready to return to the current pen through the return lane with the rest of the group. When the group is back in the original pen, there is just calmness and tranquility, as no further checking must be performed at any time of the day.

Milk transportation

By grouping the milking robots together, milk is transported for cooling in a concentrated manner, avoiding complex and large piping systems to keep milk cold and clean.

Balance tanks and holding milk tanks are all together in one sanitary room, making it quite easy to deliver milk to the milk processor. It also simplifies the washing of all piping and deposits.

Facility design

To incorporate this system on an operating farm, there is no need to modify existing barns to install milking robot boxes inside or alongside pens. With robotic batch milking, you can use your existing barn facilities while building the milking center, most likely beside the current milking parlor.

The system is easily expandable, as more robots can be added in the same arrangement if there is need to grow in cow numbers.

The concept of robotic batch milking is an option for those considering automated milking while also wanting to maintain a more conventional management style. ![]()

PHOTO 1: With robotic batch milking, a pen of cows is ushered to a holding area with individual automated milking systems positioned around the exterior.

PHOTO 2: This digital layout shows an overhead design of the milking center.

PHOTO 3: Cows freely enter each milking robot as they are available for use.

PHOTO 4: Robot rooms positioned around the holding area allow access to two of the robots.

PHOTO 5: The cowside entrance to two robots positioned side by side.

PHOTO 6: A single-pass exit alley lets cows return to their pen or be sorted into nearby treatment pens. All photos/images courtesy of Madero Dairy Systems.

Madero Dairy Systems has been focused on providing optimal solutions for large commercial dairy farms worldwide for more than 30 years. In addition to the Madero Merlin2 Robotic Batch Milking, the company also offers a fully automated barn, TMR feeding and bedding systems for these modules.

Pedro G. Madero is the CEO of Madero Dairy Systems.