Cows experience heat stress when the temperature-humidity index (THI) is above 72. During heat stress, respiration rates increase, while milk production and reproduction decrease. One practice in heat stress control is to install sprinkler systems over the feed line and in the holding pen. The objective of the sprinkler system is to wet the cow’s back, but to avoid moisture accumulation on the udder or in freestalls. Evaporative cooling occurs when the moisture is evaporated by natural or mechanical ventilation.

This article discusses guidelines for sizing and installing sprinkler systems at the feed line. The information is not intended to cover the design procedures of high-pressure fogging or evaporative-cooling systems.

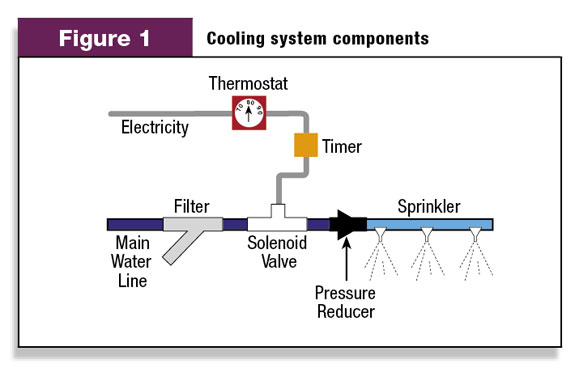

System components

System components include a timer, a thermostat, a solenoid valve, pressure reducer, piping and sprinkler nozzles (See Figure 1 ). The casing of the equipment should be waterproof and dustproof to meet electrical codes.

The thermostat should be set to turn the sprinkler on when the air temperature exceeds 70 to 75° Fahrenheit.

A thermostat will control a valve or solenoid located prior to the first nozzle. The solenoid valve controls the water flow through the pipe.

Sprinkler systems need a 15-minute to 30-minute on-off timer. A 15-minute cycle is common – the sprinkler is on for three minutes and off for the next 12 minutes. The timer should be controllable to the nearest 15 to 30 seconds.

If flow quantity is a limiting factor, then sequencing the system is an option. If there are multiple sprinkler systems, a 60-minute timer may be needed to sequence the individual sprinkler systems.

The pressure reducer is needed to limit the sprinkler line pressure at the inlet to 20 to 40 pounds per square inch depending on the recommendation of the nozzle manufacturer. This primarily is needed when the water pressure in the distribution pipe exceeds 40 pounds per square inch.

Pressure losses through the distribution pipe should not exceed five pounds per square inch. Water usage during a summer may vary from 500 to 1,500 gallons per cow depending on the weather conditions and sprinkler system used.

Water application rate

A simple design criteria of wetting rate is 0.03 gallons per square foot of wetted surface area per sprinkler on the cycle. The wetted surface area is the area wetted as the sprinkler nozzle oscillates back and forth.

Normally, a distance of six to eight feet is wetted behind the feed line. One guideline is to use six square feet per foot of feeding space. If the feed line is 100 feet long, then the wetted area per pen is 600 square feet (100 feet x 6 square feet). Therefore, 18 gallons (600 square feet x 0.03 gallons per square foot) of water is required to meet the design criteria of .03 gallons per square foot per cycle.

The water pipes must be able to deliver 18 gallons of water during the selected sprinkler “on” cycle. If the sprinkler’s cycle time is three minutes for the 18- gallon usage, the required flow rate is six gallons per minute (gpm).

Sizing of water pipe

The main distribution pipe is sized based on providing water to the number of sprinkler systems operating. If four pens are being cooled simultaneously, then the water usage per cycle rate is 72 gallons, using the above example of 18 gallons per cycle.

Using 72 gallons in three minutes requires a water flow rate of 24 gallons per minute. Sequencing of the individual sprinkler systems requires a flow rate of only six gallons per minute.

Selecting the “on” time is also critical in sizing the water pipes. If the “on” cycle time of the above sample is six minutes, then the main pipe supply water to the individual sprinkler system must be able to handle three gallons per minute (18 gallons per six minutes).

Increasing the “on” cycle time decreases the required water flow rate. The recommended flow rate in gallons per minute equals: (wetted area (sq ft) x 0.03 gal/sq ft) divided by cycle on time (min).

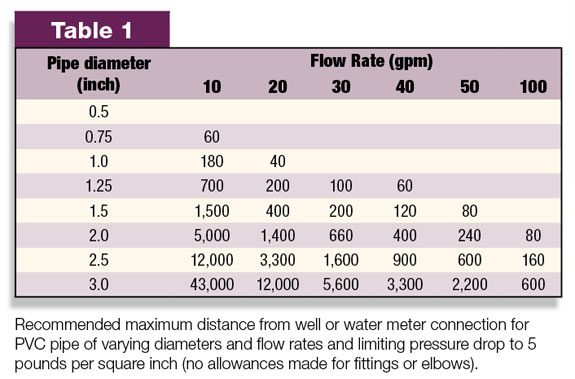

Table 1 shows the maximum distance from a well or water meter connection to the sprinkler system controller based on flow rate, PVC pipe size and limiting the pressure drop to five pounds per square inch.

Assume a producer wants to determine if a 1 1/2-inch PVC pipe will carry 27 gallons per minute for 400 feet.

Table 1 shows that, with a 30-gallon-per-minute flow rate, a 1 1/2-inch pipe should only be used if the distance is 200 feet or less. Therefore, a 2-inch PVC pipe would be selected since it can carry 30 gallons per minute up to 660 feet before exceeding the five pounds per square inch pressure drop.

A new water line for sprinkling cows may have to be added in existing facilities if the current water lines were sized to handle peak demand of the waterers.

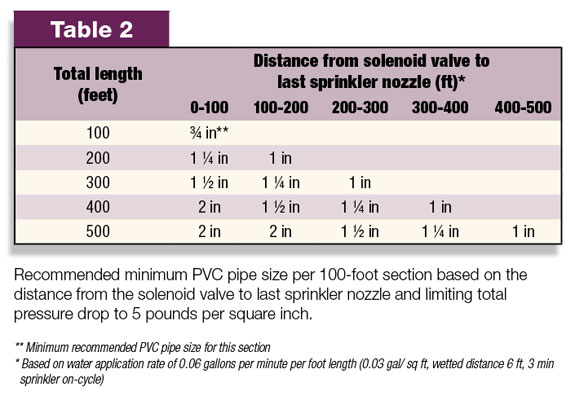

Table 2 shows the recommended minimum pipe size from the solenoid valve to the last sprinkler nozzle for the sprinkler distribution system.

This table was developed based on applying 0.06 gallons per minute per foot length of feed line (note: (0.03 gal/sq ft x 6 ft/ft length) divided by 3 min cycle = 0.06 gpm/ft length) and limiting the total pressure drop to five pounds per square inch or less.

A three-minute cycle was used in sizing the flow rate. If a feed line is 200 feet long and the solenoid valve is located at one end of the system, then the first 100 feet of pipe past the valve should be 1 1/4-inch PVC pipe and the next 100 feet should be 1-inch PVC pipe.

Another option is to bring the main distribution line to the center of the feed line. This limits the distance from the solenoid to the last nozzle to 100 feet and then 3/4-inch PVC pipe could be used.

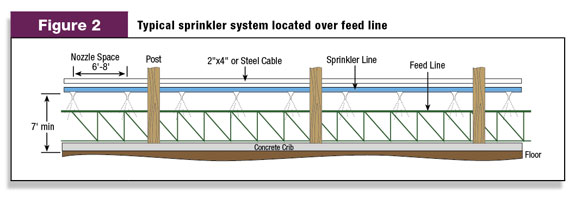

The sprinkler nozzles and pipe must be supported between the building post if post spacing is greater than four feet ( Figure 2 ).

A steel cable can be placed along the feed line and stretched tightly. The pipe can be fastened to the cable by using wire ties.

Another option is to place a 2x4 along the post and use clamps to hold the pipe in place.

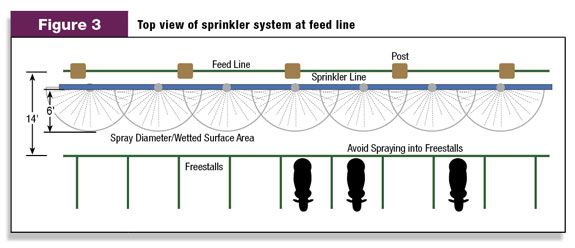

Ideally, the nozzles should be located 12 to 18 inches behind the feed line (cow side of the feed line is considered the back side) (See Figure 3 ).

The bottom of the nozzle should be seven feet above the concrete floor (See Figure 2 ).

Sprinkler nozzles

Sprinkler nozzles are rated to deliver a set number of gallons per minute (gpm) or gallons per hour (gph). An adequately sized nozzle should have a rating near 0.5 gallons per minute or 30 gallons per hour.

The nozzle pattern or diameter should be six to eight feet. Normally, there is an adjustment on the nozzle that adjusts the diameter. Nozzles can be purchased to spray water in a 180-degree or 360-degree pattern.

The 180-degree nozzle works well at the feed line. If the 360-degree nozzle is used, then the sprinkler system needs to be suspended five feet behind the feed line and spray diameter limited to eight feet.

Nozzle spacing is equal to the nozzle diameter or pattern. If the nozzle spray diameter is eight feet, then the maximum spacing of the nozzles should be eight feet on center.

It is better to reduce maximum nozzle spacing 5 to 20 percent to ensure adequate coverage where the nozzles overlap and provide allowance for wind direction. The maximum spray diameter of a nozzle should be an eight-feet diameter to avoid wetting the freestall bedding.

Operating cost

Sprinkler systems can be installed for less than $5 per foot of feed line. Sprinkler packages are available from most dairy equipment and suppliers for $200 to $300.

Most operations will require one sprinkler package per 100 feet of feed line. Normally, additional nozzles and piping are all that is required for extending the sprinkler system from 100 to 200 feet.

Beyond 200 feet, the economics of installing larger pipe to handle the high flow rates has to be compared against purchasing multiple controllers. Multiple controllers may be better, since part of a feed line can still be cooled if a component fails.

In many areas, a sprinkler system will probably operate eight to 12 hours per day and from 100 to 150 days per year. Limited data indicates about 40,000 gallons of water may be required for sprinkling 100 feet of feed line.

Based on 100 days of operation, this is equal to 800 gallons per day. Cost of rural water ranges from $1.50 to $2 per 1,000 gallons. Estimated daily cost for water is $1.50 per 100 feet of feed line or about three cents per two feet of feeding space.

Water cost can be recovered by seeing a daily increase in milk of less than one pound. An increase of 100 pounds weight of milk per cow during the summer is needed to cover the fixed and variable cost of most sprinkler systems. The life expectancy of a sprinkler system is five years.

Maintenance

Annual cleaning or replacement of some nozzles is required. Nozzles should be removed each fall and soaked in vinegar or other solutions to remove the calcium buildup due to hard water.

Water filters may be required with some water sources to remove particles that can plug nozzles. The piping should be drained in October to avoid frozen water lines. Compressed air can be used to remove all of the water from the system.

Sprinkler systems should not be placed on 24-hour timers or shut off during the night hours, particularly with 3X milking. Cows will come to the feedbunk during the night and conditions may be such that heat stress is a 24-hour problem rather than a dawn-to-dusk problem.

Summary

When the temperature-humidity index (THI) is above 72, sprinkler systems can be installed to prevent heat stress to cows. Estimated daily cost for water is about three cents per two feet of feeding space. A response of 100 pounds of milk per cow during the summer is needed to cover the fixed and variable cost of most sprinkler systems. PD

References omitted due to space but are available upon request to editor@progressivedairy.com .

—Excerpts from Kansas State University Agricultural Cooperative Extension Service

Joe Harner

Department Head,

Biological & Agricultural Engineering

Kansas State University

jharner@ksu.edu