As wheel loader technology evolves, manufacturers are developing tools that allow operators to move the machine safely and with enhanced visibility. One standout technology was introduced last year.

What is a Transparent Bucket?

First, the Transparent Bucket isn’t actually transparent. It’s not made of glass or clear acrylic. Rather, it incorporates technology that gives wheel loader operators an unobstructed view in front of the wheel loader bucket. The feature allows them to see objects or challenging terrain. This is done through the work of two cameras that use a curved projection method to show the combined image on the in-cab monitor. Between other equipment, farm materials and animals, dairy worksites can present many obstacles for operators. With a traditional bucket, the view of these obstacles can be obstructed. A Transparent Bucket enables operators to move the wheel loader on the farm more confidently, leading to more efficient work and greater machine uptime protection.

The technology allows the wheel loader operator to see directly through the bucket and to the area in front of the machine. This is achieved through camera technology that projects a supplemental view from the bucket to a monitor inside of the cab. With this new product, operators can be sure they are moving about their worksite safely.

Why is this new technology needed?

When someone hears about this new technology for the first time, they may wonder why such an option is necessary. After all, traditional buckets have been used on wheel loaders for decades. Manufacturers have made strides in recent years to increase general visibility from the wheel loader cab. These improvements have ranged from increasing the amount of glass in a cab structure to installing additional mirrors or cameras. However, no matter how much glass is in the cab, or how clean the glass is kept, the bucket will always be in an operator’s line of vision. This can be an issue for multiple reasons.

One reason is: An operator may not be the most familiar with the worksite. Say an operator had never worked on a dairy farm before. They may move across a site more cautiously than other experienced operators or crane their necks from the cab to ensure they are in full control of the bucket and nothing is in front of it. While this may not be the most pressing issue, or even something an operator would classify as an issue, it can still eat into productivity. That’s where this new technology comes into play.

How the technology works

This technology consists of an in-cab monitor and two cameras with protective guarding. One camera is mounted high, while another camera is mounted low on the front of the machine. The reason for two cameras is that a bucket moves up and down. When the bucket is low, the view of the second camera is being obstructed. Similarly, when the bucket is high, the first camera’s view is obstructed. Two cameras ensure each bucket movement is recorded.

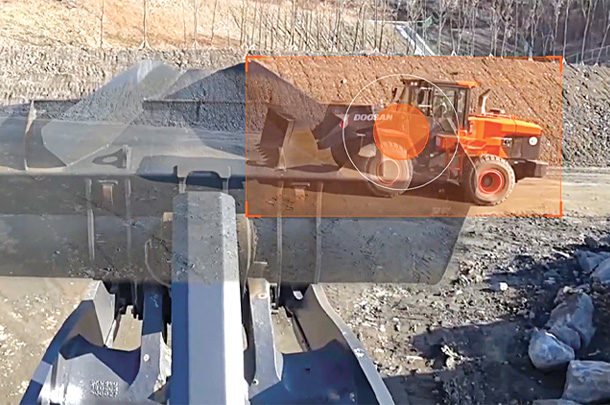

The system’s processor automatically combines the camera inputs into a single image that makes the bucket appear transparent on an in-cab monitor (photo above). This also assists with operator visibility.

Often, a wheel loader is moving forward and reverse multiple times in its work pattern. When operating a wheel loader, blind spots can develop in the front of the machine. It’s critical for an operator to have an unobstructed view of their surroundings.

These blind spots are especially noticeable when raising or lowering a bucket. With this technology, these blind spots are minimized. Additionally, the multi-camera system within and around the bucket allows the machine operator to see what’s in front of them on the in-cab monitor, whether raising a bucket to add feed to a mixer or carrying snow in the bucket before unloading it in a pile.

Minimizing blind spots allows a machine operator to move about their worksite more confidently. This confidence translates into a more productive workday. The ability to “see through” the wheel loader bucket allows operators to efficiently dig into and precisely place material where it needs to go. This innovative technology helps maximize productivity even on the busiest

dairy farms.

The Transparent Bucket is an exclusive technology option from Doosan Infracore North America.