The auto-wrap tying system is a totally mechanical operation, so all actions are started and completed by machine-driven parts.

When a bale reaches a predetermined size, the linkage attached to the take-up arm pushes a top sliding plate up to a cam. As the cam begins to be pushed forward, the side sliding plate is pushed forward until the roller under the cam releases the sliding side plate. When the sliding side plate is released, it slides down in slots machined in the side of the plate.

As the side plate is released, the clutch dog is released, and the belt-driven pulley engages the clutch dog and the auto-wrap starts the tying cycle. The second role of the sliding side plate is to open the knives as the plate slides down in the slots.

The variation you will see between models of balers is how the top sliding plate is attached to the take-up arm. On chain-type balers, the take-up arm would rotate and contact a lever. The lever would be directly attached to the top sliding plate. On belt balers, you will find various types of linkage depending on the model and year of production.

On 5-foot tall balers, there is a link which rides against the take-up arm with a pivot point in the middle and then attached by either a cable or a direct link to the top sliding plate. On 6-foot machines, there could be either a link connected to the take-up arm, example 660, or a chain and cable.

For the auto-wrap to trip, the rod on the end of the top sliding plate must either push against the back of the cam or sit in the notch of the cam and push from there. The notch in the cam only works if the baler is set to make smaller bales, since the top sliding plate needs to travel farther to trip the auto-wrap when in that position. When making full-sized or close to full-sized bales, the top sliding plate, pushing in the notch, will not release the clutch dog before the baler is overfilled.

With an empty bale chamber, the rod at the end of the sliding top plate should be behind the cam.

One cause of the auto-wrap not tripping on 5-foot tall balers is the top of the link with the roller gets bent to the side, so the roller at the top of the link no longer contacts the cam on the take-up arm.

On balers where a cable and pulley system are used, there is an idler pulley the cable is routed around. At the front of the pulley is the guide plate to keep the cable on the pulley. Over time, hay can build up in the groove of the pulley. When enough material packs in the groove, the cable will be pinched between the idler pulley and guide plate, which locks the pulley and cable in place.

When the bale is ejected, the cable cannot return to home position. Since the cable is attached to the top sliding plate, the sliding plate also does not return to home position.

On balers where the linkage is directly attached to the top sliding plate, the spring shown in the photo may not overcome the weight and position of the linkage. If the top sliding plate is not fully retracting, add a second spring to the manual trip lever. The manual trip lever moves the top sliding plate back on all models.

Over time, a situation may arise where the auto-wrap will not stop cycling. This problem is caused by the roller under the cam releasing the side sliding plate before the clutch dog is released. In situations like this, the side sliding plate is probably bent outwards. The correction is made by removing the side sliding plate and bending the plate back.

Whenever making adjustments like bending the side sliding plate, always trip the auto wrap by using the manual trip lever. If the auto-wrap trips hard or not at all, the side sliding plate was bent back too much.

If you cannot manually trip the auto-wrap, the mechanical linkage will be unable to trip it either. ![]()

PHOTO 1: With an empty bale chamber, the rod at the end of the sliding top plate should be behind the cam.

PHOTO 2: Side view

PHOTO 3: The rod should be behind the cam. If the rod is in the notch instead, then the plate with the rod is not being fully returned to the home position.

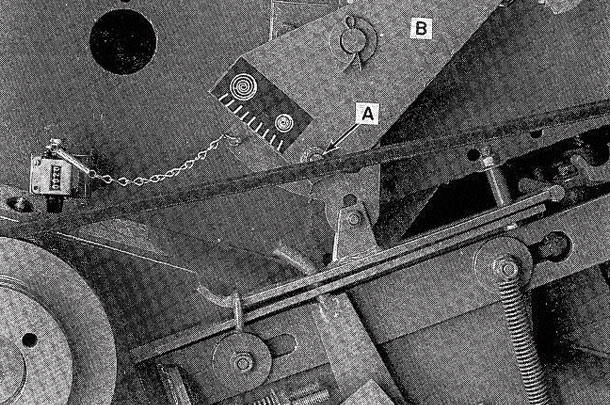

PHOTO 4: Linkage to take-up arm.

PHOTO 5: Roller Take-up arm cam.

PHOTO 6: Material packed in pulley groove. Guide plate to hold cable to pulley

PHOTO 7: On balers where the linkage is directly attached to the top sliding plate, the spring shown may not overcome the weight and position of the linkage. Photos by Mike Seckinger.

Mike Seckinger has over 44 years experience as a farm equipment mechanic in southern Indiana and says, “What I write is not intended to represent the only way to solve a problem, and it may not always be complete. If you choose to follow some of my procedures, remember to always practice safety first. Wear the correct clothing and safety equipment, and use the equipment’s safety devices.”