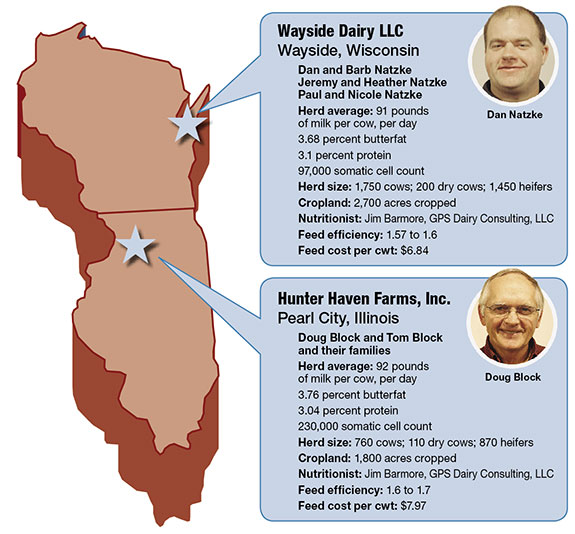

In November, Jeremy Natzke of Wayside Dairy LLC in Wayside, Wisconsin, and Doug Block of Hunter Haven Farms, Inc. in Pearl City, Illinois, were panelists for a seminar titled “Feeding the 40,000-Pound Cow” at the PDPW Feed and Nutrition Conference. The two dairymen compared notes on how they have exceeded 90-pound-per-day averages and how they believe they will capture the next 10 pounds of milk.

Describe your feeding program.

Block: We basically have four rations on the farm: a dry cow ration, a pre-fresh ration, a post-fresh ration and a dairy mix that we feed to the rest of the herd.

The majority of the cows are dried off around 60 days, but we do dry off about 20 percent of the herd at 45 days.

Those are primarily the high-producers. We start feeding the pre-fresh ration two to three weeks before they are due to freshen, bringing in heifers four to six weeks before calving.

The post-fresh ration is fed to our cows for about three weeks after they freshen.

It is pretty much the same as the main ration for our herd, except it has some dry hay and a little different premix.

Our rations are balanced for starch, sugar and rate of fermentation. It is called a low-protein ration, and all of this is based on high-quality forages. I cannot say enough about high-quality forages. Our whole ration is based around that. We just feel there is no substitute.

Natzke: We run four rations: fresh, milking, dry cow (far-off) and close-up. In the past, we had a couple of milk cow rations, but we cut back to just one because we are at such a high production level that it was actually more work and time to add the extra ration for lower-producing milk cows.

Cows receive the fresh cow ration for 21 days. All heifers go through the far dry-offs so they can get used to being with the cows. In our pre-fresh, we have cows and heifers separate because of the social challenges.

Feed consistency is a big thing. When we put out feed one day, it should be about the same as it was the prior day; otherwise, there is something going on. We do weekly forage testing and run moistures daily to make sure it is where it needs to be.

We feed bypass amino acids and blood meal. Cottonseed is a big protein source. We also feed a lot of BMR corn silage because we feel we get a better milk response and just a healthier cow in general.

The last couple of years, when corn has been high, we started feeding wheat. Now that corn is coming down, we are taking some of the wheat out and putting corn back into the ration.

What additives are you feeding?

Block: We have Rumensin in our diet at the 400-milligram to 450-milligram level. We use protected methionine in our ration, as well as Megalac-R for pre-fresh and fresh cows.

We use a yeast culture, biotin, magnesium carbonate and Zinpro for organic zinc for hoof health, immune system and – we hope – somatic cell reduction. DCAD Plus is fed to all of the fresh cows and also all of the milk cows during the summertime. We use sodium bicarbonate, OmniGen, organic selenium and SoyChlor.

Natzke: Our cost for all of our feed additives is just over $1 per day. While you may say that is quite a bit, once you put it all together with what you get out of it, we come out ahead. We work with the same nutritionist [as Block], so our additives are similar.

We feed Rumensin to every animal on the dairy to help with feed efficiency and stabilizing rumen health. We feed ReaShure to meet the choline requirement for the cows, as well as a yeast. Bovamin is something we feed to fresh cows to help with gut health and changes during the transition process.

The milk cows also get an energy booster for milk production and reproduction. Right now, we are doing a field trial using StrataG, an omega-3 fatty acid supplement, for the fresh cows. We don’t have these results yet but expect to see them in the next six months.

Are you ‘buying’ your production?

Block: No, we cannot buy milk production. It has to earn itself. We are always paying for the production, but what we are watching for is whether or not it is cost-effective. We recently switched one of our feed additives.

It cost me $4,500 last month to put this feed additive into the ration. With 750 milking cows, if you go up 1 pound of milk over 30 days at $20, it comes out to about $4,500. So, was it really cost-effective to put that in?

And did we really gain a pound of milk? In this case, there were some other things we were able to pull out by adding this additive, and we gained a pound of milk with that.

Natzke: For every dollar you spend, there has to be a return. We really rely on Jim Barmore, our nutritionist. He does a lot of research and knows which additives will give us a better bang for our buck. We also use a financial consultant to help us with budgets and determining our true cost of production.

Where do you think your production will level off?

Block: The challenge, really, is to do it year after year. We were at 100 pounds for a period of a few weeks last spring. That’s a great goal, and it is nice to hit, but I would be delighted if I could average 92 to 95 pounds for the whole year.

Natzke: I don’t think you can ever really settle on a number. I think the next goal is 95. We were consistently hitting that in July. At that time, we were in a bunker where the corn silage was processed better than the one we are in right now. I think you are always trying to raise the bar.

How do you manage your feeding program?

Block: One concern of ours has been the accuracy of the ration. We put in a computerized feed system a couple of years ago, and that has been huge. Our weighback goal is 3 percent every morning. We have averaged 2.67 percent weighback.

We have a separate mixer wagon that we put it in and weigh it every morning. We feed part of it to dry cows, and part is blended back in for our low-value pen. In summertime, when it spoils, it brings tears to my eyes – but we throw it away.

Natzke: We also strive for 3 percent weighback, and we are hitting that almost every day. We also weigh the weighbacks going in. It is entered into our Feed Supervisor program and gets fed back to dry cows and the lower pen.

In the summertime, we also throw it out if it is too hot. A couple of years ago we added a truck scale. That was really eye-opening for us. It has been a good measurement tool.

How will you gain the next 10 pounds of production?

Block: We strive to get those extra pounds of milk by doing things on time, every time, and I can’t emphasize that enough. That applies to the guys in the parlor and feeding. Do everything you can do to increase feed quality, and that means getting the agronomist and nutritionist in the same room.

We meet together because there are a lot of things that have to come together there. Our goal is to feed that cow the same consistent ration 12 months of the year.

Natzke: We want to reduce the cost per hundredweight of producing milk. Ratios are not a good economic indicator but a useful metric. When we look at cost, we look at the cost to produce a hundredweight and the margin leftover earnings at the end of the year.

Maximizing feed efficiency should never be the goal, as it would cost too much to achieve this. We also focus on solid feeding protocols with minimal variation, and we use our nutritionist to research feeds and byproducts to find out what is the best to feed.

What lessons about feeding have you learned along the way?

Block: In the beginning, we did not have enough feed space. It became a back-and-forth swing of constantly adjusting the percentage in the ration as we would run short of haylage in the spring and corn silage in the fall.

As I stand here, I can tell you that we will not run out of last year’s corn silage, and that is by design. It is that important. The other mistake we made was being slow to concentrate on cow comfort and hoof health. At one time, we had mattresses and sawdust.

When we switched to a digester and compost bedding, our lay-down rate immediately increased, and I am convinced we probably gained 4 to 6 pounds of milk just from cow comfort. The same thing happened with our breeding program. You just can’t get behind on those things.

Natzke: Don’t feed the “fu-fu dust.” Just because something may be a hot-selling product does not necessarily mean you should feed it. When milk prices were down and we discussed what we could cut, we talked about feed a lot.

That was one area that we said “no” to cutting. We were not going to skimp on nutrition. It still has to be there, and you still have to milk your cows and get your cows bred. It comes full circle.

Where will you be 10 years from now?

Block: I think 10 years from now my brother and I will be senior advisers in our dairy operation, but I am really optimistic for the next generation because of the global food opportunities. I have two sons in agribusiness, and their work is turning more and more international, and that makes me more optimistic for 10 years from now.

Natzke: Our future plans really depend on the land base. Right now, we are at a point where we use all the land that we have for manure. We are almost at the point where we are asking guys to take it or sell it off. Right now, if we added more cows, we would have to purchase more feed. I’d like to be at 2,500 to 3,000 cows, but it depends on land. PD

Peggy Coffeen

Editor

Progressive Dairyman