Corn silage kernel processors are referred to as “crackers” by many in South America, where less than one-third of dairies feed corn silage that has had the kernels processed. Kernel processing is much more popular in the U.S. because roughly ten years ago, researchers helped us understand what impact processed corn silage grain really had on rumen digestion in cattle.

This team developed the corn silage kernel processing score (KPS) and very few trending topics have caught the dairy and custom harvesting industries’ attentions like KPS. What exactly is KPS? This score encompasses a two-day laboratory process that includes drying the corn silage in an oven and then separating the starch into different sieves.

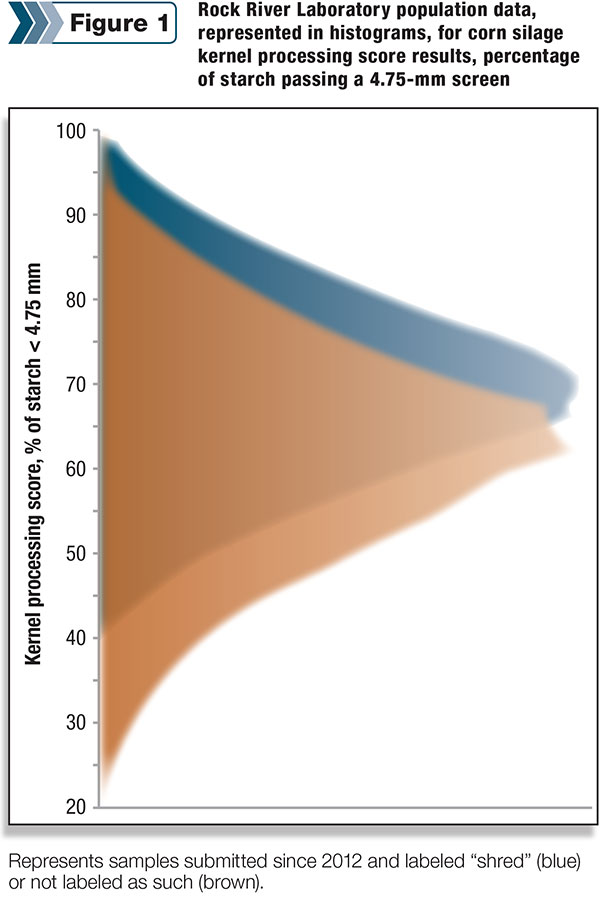

The percent of starch smaller than 4.75 mm is measured and a score is provided based on this measure.

Carrying the KPS fever pitch forward, shredding or shearing kernel processors (KP) have hit the market with some novel engineering (and names like shredlage). And because of this momentum, we field questions time and time again, “Are these processors worth the added investment?”

To answer this question, it’s important to first revisit what happens when corn grain, at silage maturity, is broken open by a processor or cutter head knives. Corn grain actually represents about 50 percent of silage yield.

Meaning, if corn silage yields 10 tons per acre (on a dry matter basis), then roughly 5 tons of corn (about 205 bushels) are harvested and ideally processed through a properly managed KP. How long does it take to harvest an acre? Now think about 200 bushels being run through the KP in that time period. It’s a mammoth task to process all of that corn.

So how does kernel processing work to improve starch digestion? Corn grain evolved and was bred as a hard seed, with protection assets built into the grain to protect the corn plant’s offspring from damage (and digestion). A water-repelling seed coat is the first protection mechanism built around the germ and starch.

Beyond the seed coat, a strong protein matrix develops as the grain matures. This protein matrix further inhibits starch digestion. Completely processing the grain, with greater than 70 percent of starch passing through a 4.75 mm screen, helps break through the seed coat and expose the protein-starch matrix.

Well-processed corn can soften faster and digest more readily because the seed coat is broken and starch surface area is vastly increased.

Does processing matter to cows? Yes. In the old school of thought, it was assumed that simply breaking the seed coat or cracking the corn kernel into halves or quarters would get the job done. However, with new research, we’ve found this simple processing is no longer adequate. Much more corn silage is fed now relative to years ago and margins are too tight.

Researchers reviewed many research papers and demonstrated that kernel processing with a 1 to 3 mm roll gap improved starch digestibility relative to wider gap settings. The old school of thought had some justification because fermentation softens starch. But do rumen bacteria and cows truly have access to all the starch and energy within well-fermented corn?

This is a substantial question and current knowledge and research leads us to answer this question as no. Kernel processing still matters to digestion and milk.

The silage fermentation process does soften the corn. However, this will not rescue a poor KPS (less than 50 percent KPS). The industry has recognized that even well-fermented corn varies substantially in KPS (Figure 1) and the goal is now “near complete kernel destruction” (greater than 80 percent KPS).

More recent research by Dr. Randy Shaver’s group at University of Wisconsin – Madison, showed increased starch digestion and milk responses in alignment with increased kernel processing using silage that had been fermented for four months but processed with two different KP.

Back to the first question posed, “Are shredding-type kernel processors worth an added investment?” Time and experience will bear the answer. To offer some field insight, commercial silage kernel processing results are summarized here. Figure 1 demonstrates KPS population results from Rock River Laboratory for corn silage samples labeled “shred-” versus those not labeled “shred-.”

There appears to be slightly greater KPS on average with samples labeled “shred-,” relative to samples not labeled as such. Also note the considerable overlap between the two groups.

Please keep in mind the histograms presented in Figure 1 are strictly observational data and do not imply cause and effect. For example, the data could also represent an impact of newer processors versus an aging non-“shred” type processor population. Shaver’s team’s research agrees with Figure 1, but interpret these observational results with caution.

Beyond processor type, do not forget that KP integrity (e.g., roll or bearing wear) and settings (roll gap and differential) are at least as important as KP type.

Some words of caution should be shared if benchmarking with KPS at harvest. Understand that benchmarks should be different than if checking fermented silage. Results for the same feed will be different in fresh, chopped corn versus the well-fermented silage because grain and starch will soften and break down.

Dr. Keith Bryan of Chr. Hansen and Professor Shaver, among others, have helped the industry understand that KPS likely improves 5 to 10 points with extended fermentation.

The water float test (separating stover from grain) is a valuable, fast and free tool to use during harvest to view kernel destruction. To conduct this on-farm test, fill a calf pail half full with water and place a few handfuls of freshly chopped whole-plant corn into the pail.

The stover floats and can be easily separated from the top, then dump the grain through a fine screen to visually assess kernel breakage. Unfortunately, fermented silage does not work with this test as it does not separate as easily.

Beyond KPS, there may be another valuable silage grain processing assessment on the horizon for commercial silage. Research is currently in process. Stay tuned for future implications. In the meantime, understand your silage cracking.

Consult with your advisers and harvesting team and discuss what impact kernel processing has for your dairy. Strive to do better if your cracking is less than ideal. In a year of low prices, “cracking” your corn further for improved starch digestion could improve milk production with minimal input costs. PD

John Goeser earned a Ph.D. in animal nutrition from the University of Wisconsin – Madison where he currently serves as an adjunct professor in the dairy science department. He also directs animal nutrition, research and innovation efforts at Rock River Lab Inc. based in Watertown, Wisconsin.

References omitted but are available upon request. Click here to email an editor.

-

John Goeser

- Director of Nutrition, Research and Innovation

- Rock River Laboratory Inc.

- Email John Goeser