In a whole farm context the focus on high-quality forage has shifted to the right-quality forage for each group of animals on the farm. This, however, is not an excuse to relax goals on producing high-quality forage. We all know that a number of factors, from weather to equipment breakdowns, can ruin the best of plans.

While it is not possible to manage the weather, steps can be taken to help manage for the weather.

To fully capitalize on matching the right-quality forage to the right group of animals, it is necessary to align forage inventories of each feed with animal numbers. To consistently do this it is critical to characterize and organize fields in a harvest schedule that captures each field when forage quality is high. This process needs to be dynamic, not static.

Step One

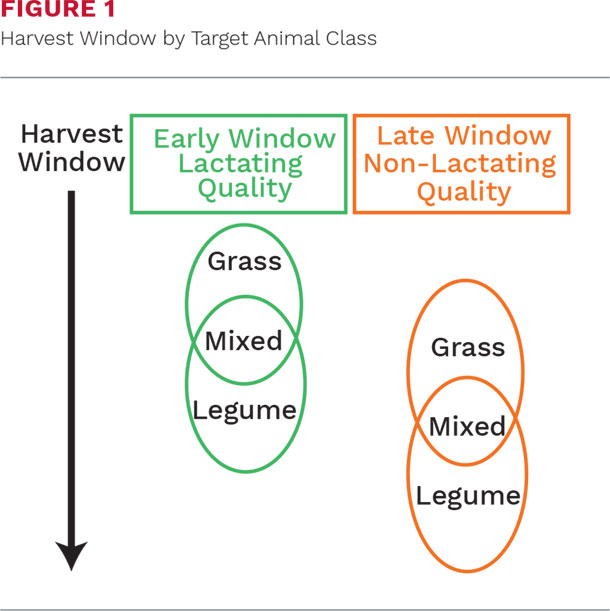

Have the mindset that each and every field on the farm has the potential to produce feed appropriate for high-producing, lactating cattle. Factors, such as plant species and soil drainage, will certainly influence the likelihood of capturing that high quality. In the Northeast, where grasses and grass legume mixes are common, the general order for harvest is shown in Figure 1.

While grasses require the earliest harvest timing, well managed grasses continue to prove their merit in rations for high-producing lactating animals, with harvest timing being key to quality.

“While grass species and variety selection, as well as fertilization issues are important, harvest management will determine the success or failure of grass silage as high-producing dairy cow forage,” reported Cherney and Cherney in a “Feeding grass to dairy cows” article published by Forages.

Additionally, nitrogen management is instrumental in bolstering grass performance, according to “Fertilization of perennial grasses” by Cherney et al. in Forages.

Harvest timing for first harvest in the spring is critical to the quality of that cutting and to set the stage for subsequent harvest. Information on timing harvest is discussed in the PRO-DAIRY Forage Management Sheet: Monitoring 1st cut harvest timing.

Step Two

Acknowledge that despite our best intentions, some fields will not be harvested at optimum timing, leading to the need for a dynamic harvest plan. If we set the goal for maximum forage quality from each field, weather, logistics and other unknowns will likely provide you with the lower quality feeds you need for non-lactating animals.

Furthermore, to be in the position of selling high-quality forage and buying lower quality forage is certainly desired over the inverse.

Many farms identify fields they anticipate to harvest for “heifer feed” in advance. These fields may contain more grass or may be poorly drained, causing harvest delays many years.

While these fields are more likely to be harvested at a later stage on any given year, if you have planned this in advance, you have sealed their fate before the harvest season begins. This approach certainly assures you will have adequate feed of a quality suitable for non-lactating animals, but that should not be the goal. The goal should be to assure an abundance of lactating quality feed and let the rest play out as it may.

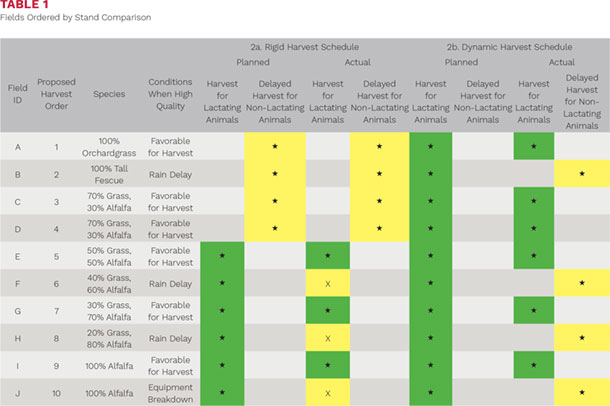

Table 1 illustrates a simple example of ordering 10 fields for harvest by stand composition, as well as a scenario of likely conditions at the time of harvest needed to achieve high-quality forage.

Click here or on the image above to view it at full size or in a new window.

In both cases the goal is to capture six fields at the desired high quality needed for lactating animals and four fields for non-lactating animals.

The Rigid Harvest Schedule in Table 2a depicts what is likely to happen when a set of fields (four fields) are predefined as non-lactating quality feed and consequently ignored at their optimum harvest timing. This leaves six fields to meet the needs of lactating animals. However, a not uncommon scenario of conditions during this sample harvest season results in only 50 percent of the fields planned for lactating quality feed actually meeting the standards.

By comparison, the Dynamic Harvest Schedule in Table 2b illustrates a strategy where all 10 fields are targeted for high-quality feed and through the same sequence of conditions results in six fields harvested at the standards for lactating animals, with 100 percent meeting the desired standards, and still provides the four fields needed for non-lactating animals. With this strategy you are able to manage for the weather, instead of letting the weather manage you.

While this example simply uses fields rather than actual acreage needed, and is focused on an individual cutting, it provides the framework needed to implement this approach. The same process often works itself out with multiple cuttings over the course of a season, as well as for harvest of other forage crops.

A similar approach was evaluated in a California study where researchers compared yields and economics of a “sequential” cutting system versus a “staggered” cutting system for alfalfa. The sequential system is described as “Habit, the field’s proximity to the headquarters, or the dryness of a field typically determines the harvest order.

Once an order is established, the same harvest sequence is followed for each subsequent cutting.” It also states that, “It is very easy to just miss producing ‘dairy quality’ and end up harvesting much of the alfalfa in one of the least profitable time periods” with this approach, according to an article by Orloff and Putnam in a Proceedings of the Western Alfalfa and Forage Conference.

In contrast “A ‘staggered’ cutting schedule strategy, which targets some harvests for quality and others for yield and improved stand life, may be an effective approach. The number of ‘dairy-quality’ cuttings was increased using a staggered cutting order.”

Joe Lawrence is a dairy forage systems specialist with Cornell CALS PRO-DAIRY. Email Joe Lawrence.

This article appeared in PRO-DAIRY’s The Manager in March 2018. To learn more about Cornell CALS PRO-DAIRY program, visit PRO-DAIRY Cornell CALS.