Current dairy economics result in very tight margins. Feed cost continues to be a dairy’s biggest expense in milk production. A comprehensive and detailed analysis of TMR preparation and delivery often reveals ways to improve milk production while reducing feed shrink, fuel and labor costs. Over the last five years, I’ve conducted many TMR audits. Whenever possible, I use the manager’s own “electronic feed monitoring system” or EFMS.

An EFMS can be an excellent source of feeding management information for herd managers, helping to lower feed cost and improve herd performance. However, many dairies do not use their EFMS to its full capability.

Most use the following standard EFMS features:

• Intake tracking

• Feed cost measurement

• Feed usage measurement

• Tracking pen count

• Facilitating ration adjustments

• Determining load size

• Facilitating ingredient loading order

These features are extremely valuable. But there is much more to be learned from EFMS. The manager also can use the EFMS to monitor employee performance, particularly the performance of the feeder.

When visiting with dairy owners and managers, I ask questions about their feeder, focusing on current feeding procedures, protocols and expectations. The last question I ask is: “What kind of job does your feeder do?”

The most common answer is, “He’s a good feeder.”

When I ask what makes their feeder a good feeder, the common answers are:

• Shows up on time

• Cows have feed

• Doesn’t bust stuff

Rarely mentioned are the feeder’s performance on the job, his personal accountability or his performance in any form of training and ongoing evaluation.

A feeder is responsible for a very important area, which amounts to more than 50 percent of a dairy’s cost of production. Most herd managers regularly evaluate the expected performance for their reproduction program, fresh cow health and parlor performance. However, it’s rare to see routine feeder monitoring and training.

Communication is vital to any successful feeding program. The nature of the feeding routine keeps the feeder working “behind the flow” of the dairy. He manages feeding equipment and ingredient inventories. And, of course, he is responsible for timely delivery of well-mixed rations to the dairy herd.

Communication breakdowns can occur easily among those operating and supplying the dairy: Feeder, relief feeder, herd manager, herd owner, nutritionist, ingredient and feed product suppliers, and equipment dealers.

Their normal areas of daily communication include:

• Changes in animal pen counts

• Forage dry matter

• Ration and ingredient changes

• Changes in forage inventory and face management

• Managing ingredient delivery, storage and processing

• Managing feeding equipment and maintenance

Tracking software in the EFMS can improve these normal areas of communication and lower the potential for human error. The dairy manager also can use the EFMS to monitor, communicate, manage and educate the feeder, who really is one of the most important members of the dairy team.

Operator performance graphs in the typical EFMS enable the manager to monitor the feeder’s performance. Three figures – dry matter intake (by pen or group), pen feeding times and load accuracy – illustrate the following examples.

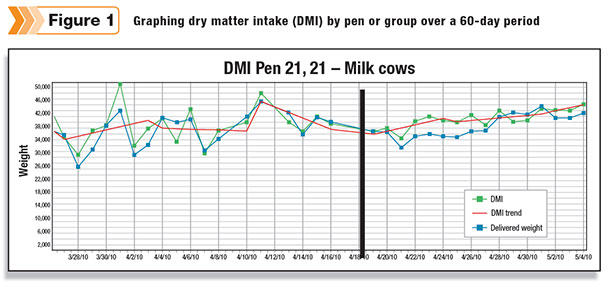

Figure 1

Graphing dry matter intake by pen or group over a 60-day period is useful to check for trends.

In this example, pen dry matter intake measurements reveal up-and-down intake in the first 30 days, shown to the left of the vertical line. There could be a number of causes for such irregular intake.

However, in this specific case, the feeder caused the problem by overcompensating the amount of TMR fed. He was “slug feeding.”

A feeding delivery management change was made, with the result shown to the right of the vertical line. During this 30-day period, the feeder could only increase or decrease the TMR 1 to 3 percent of DMI per cow per day. The result was a steady increase of DMI. The cows responded positively to the gradual feed changes.

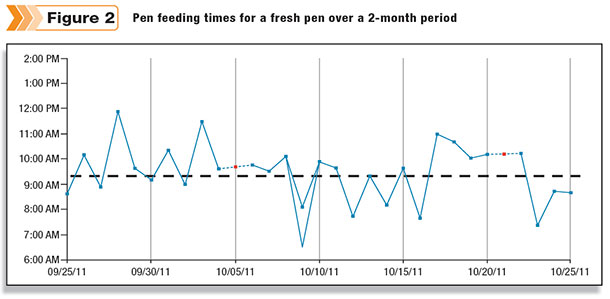

Figure 2

This figure shows pen feeding times (“drop times”) for a fresh pen over a two-month period. The pen was fed TMR once a day. The horizontal line indicates when the TMR should have been delivered. However, the graph shows the actual, irregular feeding times. Drop times varied as much as two hours.

A goal would be to feed the TMR within 15 minutes of the scheduled feeding time. It is important to maintain a consistent TMR feeding time for a fresh cow in order to establish a normal eating pattern. A consistent TMR feeding time also helps track the pen’s DMI more accurately.

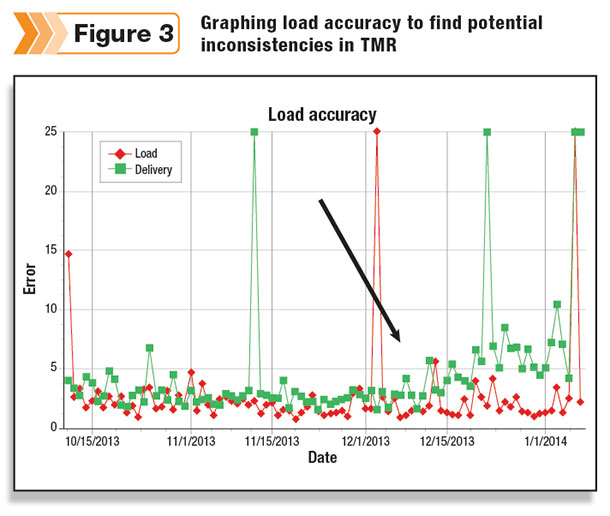

Figure 3

Load accuracy or “recipe accuracy” is another valuable tool to determine whether the feeder is mixing and delivering a daily consistent TMR.

This 60-day figure indicates that accuracy declined in December. Such declines should generate questions and discussions with the feeder.

On any dairy, many different challenges can cause inaccuracies in the mixing and delivery of a consistent TMR. Electronic feed monitoring systems offer the opportunity to better track the performance of the dairy’s feeding program.

In addition to the basic EFMS measurements, the owner or herd manager can graph the performance of his feeder, which can help control feed costs and improve herd performance.

There’s a lot more functionality in EFMS systems than most dairies use. With no more out-of-pocket expense, owners and herd managers may uncover new ways to improve their dairy business. PD

Don Martell, PAS, is a dairy field technical specialist with Diamond V. Contact him by email .