With your 2013 harvest safely packed away, now would be a good time to think back and see if you can do anything better this year. With forage representing 50 to 70 percent of most diets, the need for consistency and quality is paramount, especially as we move to even higher-forage rations, as was pointed out by all three presenters on a recent webinar, “Capture the Benefits of a High-Forage Ration.”

As so often occurs, the weather last year wreaked havoc in some areas of the country. This led to an increased use of fall-planted and winter-planted small grains, as these can be harvested early the following spring to supplement rations if feed is short and have proven capable of providing high-quality forages.

If it’s likely you’ll be short of forage in 2014, making ration adjustments now will help in the long run. Buying some extra feed early will also spread the cost out over a longer period, reducing the impact in early spring when your agronomy expenses will be high.

It will also allow you to make smaller ration changes over a longer period, reducing the overall impact on the rumen – rumen bugs take time to adapt to any change, especially large ones.

There are a few other things you can do on the farm right now to get the most out of your 2013 forages.

• Feedout management: Dry matter losses at feedout can easily be 20 percent or more. Keeping a tight, clean, straight (perpendicular to the ground) face will reduce the surface area exposed to air, reducing dry matter losses and maintaining a higher feed quality.

To help ensure this, when removing feed from the face of any storage structure, never dig in and up. Rather, remove feed from the top down using a shaver or facer or by shearing across the face of the feed with the edge of the bucket.

• Feed storage inspection: I recommend monthly checks. Bear in mind that air and water ingress are both highly undesirable; seal any holes and reseal any exposed feed not being used. Look out for previously hidden damage as the snow melts. With bags in particular, keep any vegetation trimmed well back or remove it completely so the area is less inviting to animals.

Thinking forward, is there anything you can change in the 2014 harvest to further enhance your forage program? Consider the following questions:

Can you improve on the size or type of storage facility you use?

• Size: Operations often outgrow their forage storage capacity due, for instance, to the addition of more cattle (more milking cows, higher replacement rate or raising of youngstock) or feeding higher-forage rations. This leads to overfilling existing structures, which increases potential feed loss and is unsafe.

• Type: Would a different option suit you better for all or some of your forage?

If you plan to make changes, make sure you consider all the options carefully and take account of any future plans, in particular the potential for further expansion.

Can you get more from your forages?

One obvious thing to look at is corn silage kernel processing, as failure to do this properly will result in under-utilization of the starch, reducing energy availability. Check it out by sending samples to a commercial feed testing lab for a corn silage processing score (CSPS).

Discuss the results with your nutritionist and, if there are any issues, either take it up with your custom harvester or make adjustments to your own equipment.

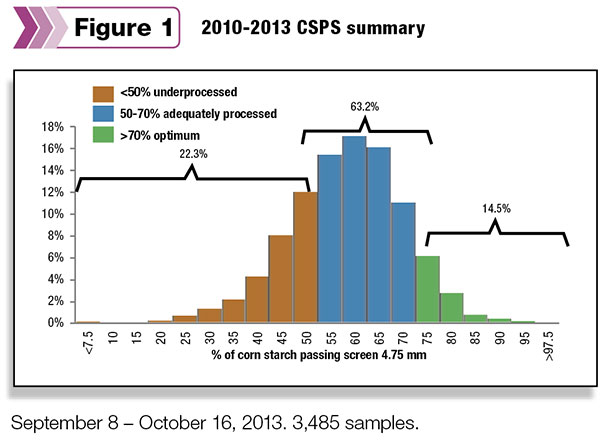

According to Dairyland Labs (Arcadia, Wisconsin), of the 3,485 samples submitted for CSPS testing over the past four years ( Figure 1 ), over 20 percent failed to achieve an adequate score and only 15 percent were optimal.

Currently, there is a lot of interest in shredlage, a new harvesting method that aims to improve energy availability. Over 250 choppers across the country were equipped with the shredlage unit last season – stay tuned for the latest research results.

Are your feeds packed adequately?

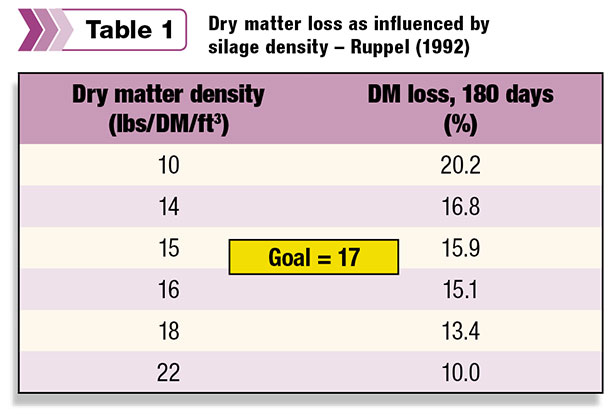

Dry matter loss ( Table 1 ) and feed quality are greatly impacted by the packing density of your forages. I recommend you aim for 17 pounds dry matter per cubic foot, which may mean making changes to some or all of the following: increase packing time, packing weight or number of packers; reduce packing layer thickness.

You could also slow the delivery rate of fresh-chopped forage, though this is usually not possible. Density is also affected by the type of the storage structure and how it is filled. The recommended slope for either a drive-over pile or the crown of a bunker is a minimum of three-to-one.

I would advise nearer four-to-one – you need to be able to drive on it to pack it properly. The University of Wisconsin – Madison forage team has created a host of spreadsheets that will help ensure proper packing is achieved.

Are your bunkers or piles covered and sealed properly?

Unfortunately, today we still see uncovered feed piles. This is amazing, as research shows you can lose 50 percent of the feed in the top 3 to 4 feet of an uncovered feed pile. Some producers still accept this as “normal” and “unavoidable,” but it isn’t. Why spend a lot of time, effort and money harvesting a crop to waste half of it later?

It takes a bit of extra effort to cover a pile or bunker, but it will be well worth it. With bunkers, you will get the best seal if you line the walls with plastic sheeting, allowing plenty of overlap with the top sheets. In all cases, make sure the plastic is tight against the forage – using an oxygen-barrier film for the inner sheet will provide the best result.

Weight the top cover to prevent it flapping or billowing, as this will pump air in. You can use touching tires or a heavy woven tarp and some gravel bags, taking extra care along the edges and seams. For best results, choose quality products with independent and published research.

Are you getting the most from your inoculant?

Leading forage researchers recommend using an inoculant – but not just any inoculant, one from a reputable company and with ample independent, published research behind it.

Be cautious, as there are inoculants on the market that have little, if any, research to support them. Note, too, that buying an inoculant based solely on price per ton alone might not actually be the best “bang for your buck.” It is return on investment that counts.

Remember, using an inoculant will not make up for poor harvesting procedures. They aim to improve the silage fermentation through a faster reduction in pH and a better use of the available sugars.

This, in turn, reduces dry matter loss and preserves more of the original forage nutrients, including protein. The end result is a higher-quality feed leading to increased milk or meat production from the same amount of silage.

Consistent high-quality forages are the cornerstone of an economically sound nutritional program. To ensure you achieve this goal, you need to plan well ahead. A bit of extra effort now will pay dividends later. PD

Isaac Mayer is the North American sales manager for Ecosyl Products Inc. Contact him by email .

Isaac Mayer

Sales Manager

Ecosyl Products Inc.