A modern lactating dairy cow produces a high level of metabolic heat because of her high dry matter (DM) intake, efficient rumen fermentation and prolific milk yield. She is, in effect, a fine-tuned bovine athlete with a daily energy turnover up to four times greater than maintenance level.

An equivalent comparison would be a competitor in the Tour de France. To achieve top performance in both instances, there is a need for good hydration, clean and easily digested food, plus a way to stay cool and fight overexertion.

Response during heat stress

The bovine athlete is relatively cold-tolerant but is extremely sensitive to heat and humidity challenges. Research shows high-performing lactating dairy cows begin to experience heat stress and significant loss of daily milk yield when the temperature-humidity index (THI) reaches 65 to 68.

Just 17 hours’ exposure to a constant THI of 68 or higher can decrease milk production of high-yielding cows by 4 to 5 pounds per cow per day. Other documented negative effects include loss of body condition, lower milk component content, significant drops in pregnancy rates, higher incidence of abortions and increased incidence of metabolic health problems and death loss post-calving.

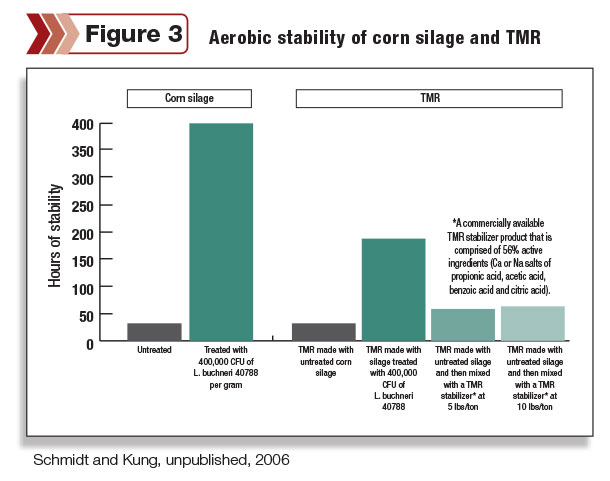

Cattle cannot dissipate heat loads effectively, so several physical and metabolic adaptations (Figure 1) occur to help mitigate the load: decreased DM intake, reduction in the rate of feed passage (more fermentation time in the rumen), rumen contractions decline (less rumen fluid mixing, which leads to more acid hot spots on the rumen wall); additionally, the internal buffering capacity is reduced (due to panting and bicarbonate excretion in the urine).

A heat-stressed lactating dairy cow is at the greatest risk of subacute ruminal acidosis (SARA).

These responses are the result of the bovine athlete going into “survival mode” due to heat stress. In this mode, she partitions nutrients away from reproduction and performance in an effort to return to homeostasis. Producers can overcome these responses through management practices as well as feed and nutrition strategies that minimize exposure to the effects of heat stress and optimize rumen function.

Cow environment

The first priority is to provide efficient heat abatement in the barns or outdoor pens to mitigate heat stress. Designs and budget vary, but some combination of shade, soakers, misters and fans should be employed. Cooling is also highly recommended in the holding area, and operations should avoid protocols that call for lock-up or vaccinations in the middle of the day.

It also is important to observe and repair the physical environment of the feedbunk. If it is badly worn or pitted, it can deter ideal feeding behavior and lower intake levels further. Cows prefer to eat from a smooth and slick sealed surface at least 6 inches above the pen floor.

Evaluating the ration

Adding probiotic active dry yeast (ADY) can support good rumen function overall – both in times of heat stress and during optimal production environments. Probiotics work to increase fiber digestion throughout all life stages of dairy cattle.

When cattle are heat-stressed, adding a probiotic can limit production losses. Not all probiotics work in the same way or will elicit the same response.

For example, cows supplemented with a particular rumen-specific strain of probiotic ADY, Saccharomyces cerevisiae, have been shown to spend more time above the SARA threshold, increase 3.5 percent fat-corrected milk by 2.1 pounds per day and improve feed efficiency by 2.9 percent in temperate environmental conditions.

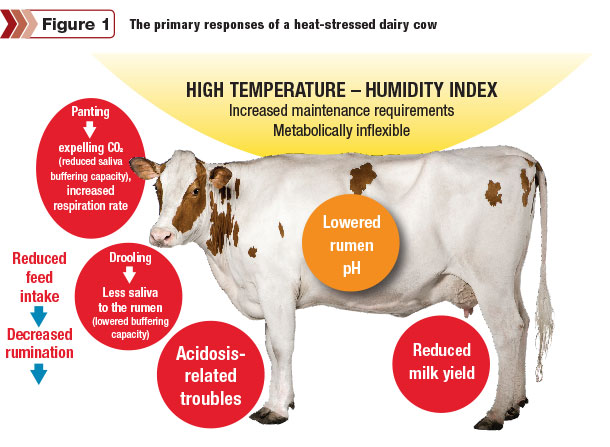

Under heat stress, a higher feeding rate of the same strain of S. cerevisiae resulted in more efficient level of production (Figure 2). In fact, this rumen-specific strain of ADY has received a functionality claim from the FDA stating that supplementation with yeast can “aid in maintaining cellulolytic bacteria population in the rumen of animals fed greater than 50 percent concentrate.”

Hot cows hate hot feed

As ambient temperatures rise, aerobically unstable ensiled feedstuffs and moist commodities can undermine the TMR quality, DM intake and milk production.

Heating and spoilage in TMRs can usually be traced back to ensiled crops or moist grains that are aerobically unstable due to indigenous wild spoilage yeast populations that have not been controlled by a silage inoculant.

When ambient temperatures are 65ºF and above, spoilage yeasts can double in number every two hours in the exposed surfaces of silage bunks, bags or drop piles. When aerobically unstable feedstuffs are mixed into the TMR, spoilage yeasts have access to highly digestible nutrients and can multiply even when an operation moves to feeding multiple times per day.

The problem is only compounded when the TMR is eaten by a heat-stressed cow with challenged rumen function, which can lead to reduction in milk and component yield. In studies with spoiled high-moisture shelled corn added to the TMR, average milk yield was reduced by 3 pounds per cow within 14 days with no depression in DM intake.

Unstable forages and moist feeds mixed into TMRs can give sudden and unpredictable losses in production with no hint of appetite loss. Another study showed that high levels of spoilage yeast in feed can exacerbate milkfat depression.

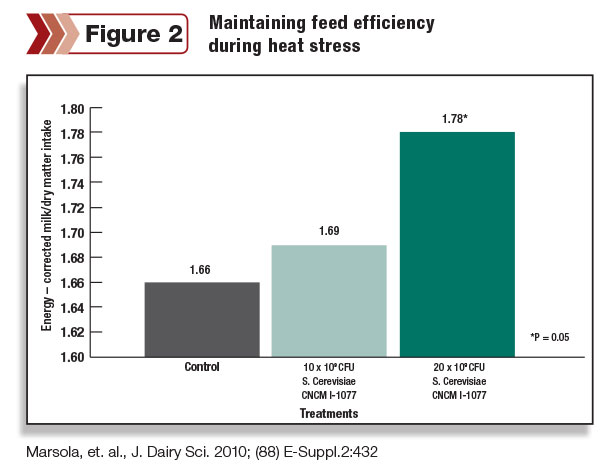

A management approach is to use TMR-stabilizing products. However, this does not address spoilage yeast growth in the primary ingredient or the associated DM and nutrient losses in the pile. Furthermore, TMR stabilizers used at the recommended label application rates can be expensive, ranging from $0.15 to $0.20 per milk cow per day.

A better solution is to ensure the ensiled forage and high-moisture grain inventories are treated with a research-proven and FDA-approved forage inoculant like Lactobacillus buchneri at the time of harvest, using the recommended effective application levels. Independent peer-reviewed research shows that a specific strain of L. buchneri increases aerobic stability in the primary forage and TMR, and increases milk and component yield (Figure 3).

Feed management

Many nutritionists and farm management teams employ added tactics to assist cows through periods of heat stress, such as:

- Ensuring that cool, clean fresh water is always available. The requirement for this vital nutrient increases in parallel to the THI challenge, with cows requiring more than 70 percent more water during times of severe heat stress.

- Establishing management programs to produce cool, palatable, well-fermented and digestible ensiled feeds to help maintain DM intake.

- Adjusting the dietary cation-anion difference (DCAD) to be in excess of +300 meq per kg of DM, monitoring rumen unsaturated fatty acid loads and increasing the energy density of the diet.

- Including rumen-specific ADY probiotics. Under greater levels of rumen challenge, a higher feeding rate of S. cerevisiae – 20 billion colony-forming units per cow daily – has resulted in more time above rumen pH 5.8, less rumen lactate, no change in DM intake, more milk component yield and a more efficient level of production.

- Adjusting mixing and feeding protocols to feed multiple times per day, with the majority of the DM delivered at the end of the day or at night. This keeps the TMR fresher in the feedbunk and encourages cows to eat and be more active during the cooler evening and nighttime hours.

- Frequent TMR push-ups and disposal of spoiled TMR or refusals.

Support your athletes

Lactating dairy cows are athletes built for milk production, but they are not equipped to maintain high performance levels during times of heat stress. Every dairy operation needs to be prepared for the temperature and humidity to rise.

Provide heat abatement within the environment, customized to your region and barn. Then work with your nutritionist to establish feeding and management programs to help these athletes perform at their optimal level – even during heat stress. PD

Bob Charley is forage products manager, and Renato Schmidt and Tony Hall are in technical services. All are with Lallemand Animal Nutrition.

References omitted due to spacebut are available upon request. Click here to email an editor.