For over a decade, the importance and the value of balancing for specific amino acids in dairy cow diets has been a very hot topic. Amino acids play a direct role in a cow’s metabolism including milk production and milk protein synthesis. The challenge for researchers and scientists is figuring out which amino acids are the most important for producing milk and milk components and, most importantly, how any of this helps the dairy farmer make any money.

Proteins are, of course, those biochemical compounds necessary for biological functions and are a part of nearly anything that makes our bodies function.

They are constructed of specific sequences of amino acids. When an amino acid that is required in a particular protein is not available in sufficient quantity, the protein cannot be made.

We can think of amino acids as a set of children’s Lego blocks. As a simple example, a particular protein may require red, blue and green blocks in a repeatable sequence of red, blue and green. The complete protein requires 30 blocks – 10 red, 10 blue and 10 green.

But in this case there are only five green blocks available. So the sequence cannot be completed after the fifth green block is used and we have only red and blue blocks left – and an incomplete protein is of little or no use and cannot contribute anything to a cow’s metabolism. It’s wasted and has to be disposed of. The green block is called the limiting amino acid.

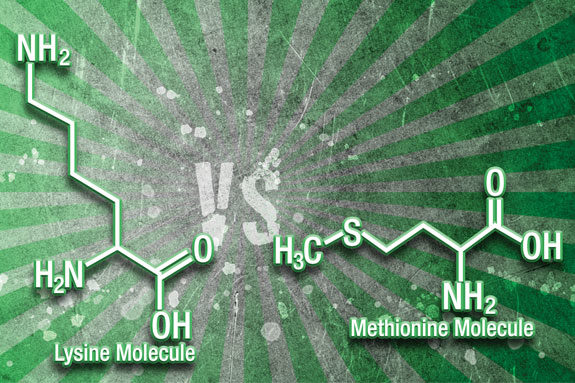

Research has determined that, especially in high-producing dairy cow diets that utilize high levels of corn, the amino acids methionine and lysine are the first and second limiting amino acids.

In diets in which grasses and legumes are the predominant forage, the amino acid histidine has been found to be the first limiting amino acid.

Diets that are made up of a high percentage of only one particular feedstuff can easily be deficient in an essential amino acid.

As a general rule, dairy cow diets should be formulated to include a variety of different feedstuffs to avoid limiting one or more essential amino acids.

Methionine is most often the first limiting amino acid for milk protein production in the U.S. Lysine has been determined to be a significant driver of milk production.

Milk protein production and protein synthesis is limited by the amino acid that is in shortest supply relative to the cow’s requirement. Balancing diets for the optimal levels of metabolizable amino acids can be a challenge.

Fortunately, the cow produces much of its metabolizable protein from the expired rumen microbes that exit the rumen and move into the small intestine where it’s absorbed and metabolized.

Microbial protein has an excellent supply of lysine and methionine, and a great deal of research is being done to increase rumen microbial protein.

Much has already been written on the importance of balancing carbohydrates and evaluating starches and fiber digestion to maximize rumen microbial protein and providing adequate rumen-degradable protein (RDP) in the diet.

In the small intestine, both lysine and methionine must be metabolized in specific quantities, such as 200 grams and 60 grams, as well as maintaining a specific ratio.

However, the metabolizable amino acids available from microbial protein do not supply enough total lysine and methionine to meet the milk production required by our high-production modern dairy cows.

Back in 2000, the U.S. dairy industry began valuing milk based on the three primary solid components that milk is made of – fat, protein (primarily casein and whey) and the remaining solids (primarily lactose).

As the market value of casein and whey has risen over the years, a concerted effort was mounted to figure out how to increase milk protein levels in milk.

Feedstuffs with optimal lysine and methionine profiles such as fish meal and bone and blood meal became popular as sources of rumen-undegradable protein (RUP) that supplied additional metabolizable amino acids to the small intestine.

Roasted soybean products and corn distillers grain have also been used to provide bypass lysine and methionine.

The challenge with supplementing amino acids in diets is that they can’t just be fed in a plain, unprotected form. Most, if not all, of an unprotected amino acid will be absorbed in the rumen and utilized in other ways and never make it to the small intestine.

And the cost and consistency of RUP feedstuffs have long been a continuing challenge, as well. So the focus has been on developing rumen-protected lysine and methionine products that will deliver a predictable and reliable level of those limiting amino acids to the small intestine to complement the microbial protein.

With the increasing popularity of grass-based diets that limit the use of purchased proteins or cereal grains, histidine is known to be limiting and, in the future, we may see a protected histidine product come to the market as well.

In recent years, scientists have been able to create rumen-protected methionine products that deliver a predictable level of methionine to the small intestine.

This was a big step in being able to both predict and deliver metabolizable methionine relative to what was, at best, an educated guess as to the actual levels of bypass lysine that came from feedstuffs.

Developing a rumen-protected lysine product proved to be much more challenging for scientists because of the molecular makeup of the lysine molecule and how it binds to other materials, which affects its ability to bypass the rumen and then still be made available for absorption in the small intestine.

So why are we trying to figure out this amino acid puzzle, anyway?

First are both the intrinsic and virtuous goals of more completely understanding the biology of cows’ metabolisms so we can improve the value of the milk they produce along with feeding efficiencies – and ultimately the profitability – of our cows and our dairy businesses.

Second and closely associated with the first reason is the cost issue and the fact that protein is expensive. Decreasing the cost of protein in dairy diets will mean money in the pocket of dairy farmers.

Third are the environmental concerns and costs associated with nutrient management and nitrogen pollution. Improving nitrogen efficiency in cows means reducing nitrogen being released into waterways, aquifers and the atmosphere.

Fourth, the use of animal byproducts as sources of RUP has been met with a lot of criticism.

This article will not go into the specifics of how much metabolizable lysine and methionine are necessary to meet milk production and milk protein requirements. Nor is this the place to debate the efficacy of the different products on the market today.

The important things to bear in mind are that there are many years of research supporting the science of feeding specific metabolizable amino acid levels that does result in both improved milk production and improved components.

Along with that, balancing dairy diets to include rumen-protected lysine and methionine is a complicated matter and these products are not just “silver bullets” that can be carelessly or half-heartedly included in diets with the hope that something great will happen to the milk.

Commercial rumen bypass methionine products have been around for a while and this discussion will not endorse or evaluate how they work.

What should the dairy farmer expect?

First, they have to be sure that everything else on the dairy is working correctly. Addressing critical management areas such as knowing dry matter intakes and the moisture content of silages as well as focusing on high-quality feeds, days-in-milk, cow comfort, feedbunk management, vitamin and minerals and water quality can add a gallon of milk to a cow’s daily production without ever addressing lysine and methionine levels.

Holstein herds that can’t manage a 60-pound average have other things that need to be fixed before focusing on amino acids.

A primary reason for developing the new commercial bypass lysine products for dairy diets is to replace blood meal and other animal proteins as a lysine source.

Feedstuffs providing RUP in a ration can be reduced or eliminated from that ration when commercial bypass amino acid products are added. Space in the ration may allow for less-expensive feedstuffs, as well.

One industry leader commented, “We’ve known for a long time that a bypass lysine product that really worked would provide essentially unparalleled benefits to the dairy industry.”

In just the past few years, a number of rumen-protected lysine products have emerged:

• AminoShure-L from Balchem Corporation (Balchem recently discontinued marketing AminoShure-L to re-evaluate its efficacy.)

• Lysine 35 from JEFO Nutrition

• MetaboLys from H.J. Baker

• LysiPEARL from Kemin Products

• MEGAMINE-L from Church and Dwight (Arm & Hammer Animal Nutrition)

The bypass lysine products are fairly new and do not have a long track record to evaluate. These products are not inexpensive, and the dairy farmer and nutritionist should be putting a really sharp pencil to the paper as they contemplate the cost and perceived value of improving protein efficiency.

The dairy farmer should always consider the value of these products on their efficacy in improving the net value of milk. Income over feed cost (IOFC) should always be tracked and evaluated.

Field trials for the various lysine products have shown increases in milk production along with both butterfat and protein. Milk production responses are often 3 to 4 lbs (e.g., 70 to 74 lbs).

Milk protein increases can be two points (e.g., 3.01 to 3.21) and butterfat often increases a point, as well. The IOFC in many of these trials can range from 20 to 60 cents per cow per day.

In order to justify the inclusion of commercial bypass amino acid products, the net value of milk must increase by either increasing total volume of milk components or decreasing the net feed cost per cow.

Every dairy farmer must make an individual decision as to the financial value of these products. Another metric to consider is return-on-investment (ROI).

A minimum ROI of 2-to-1 should certainly be a realistic expectation. If an ROI of 2-to-1 can’t be realized, try another product.

The price of milk protein in one U.S. Federal Marketing Order (FMO) during the summer of 2011 was about $3.80 per pound. The difference in milk revenue for a cow producing 70 lbs of milk per day with a milk protein value of 2.95 percent protein is about 70¢ lower than if the protein test were 3.2 percent.

(This assumes butterfat and other solids stayed the same in this case.) A year later in mid-2012, with milk prices down about $4 per cwt, there’s still about 50¢ per cow left on the table with that same spread in protein test. So, regardless if milk is $18 per cwt or $22 per cwt, increasing total pounds of milk protein will add value to the milk being shipped, and a decent ROI can be expected by balancing for specific metabolizable amino acids.

Dr. Charles Schwab, an expert in methionine and lysine metabolism, noted that the results of a 10-herd field study in 2006 indicated a ROI ranging from 1.1- to 5.5-to-1, with an average ROI of 3.35-to-1. This means that for every $1 invested in balancing for metabolizable amino acids, there was a return of $3.35.

Schwab said that milk protein prices at $3.00 per lb or higher, even with high feed costs, make balancing diets for lysine and methionine an attractive option for increasing dairy herd profitability.

It’s no longer uncommon to hear reports of increases in milk protein and milk fat concentrations of 0.20 to 0.25 and 0.10 to 0.15 percentage units, respectively, and 3 to 5 lbs more milk as a result of balancing for metabolizable amino acids.Increasing total milk production as well as components will add even more value to the milk – the key here is to produce more pounds of solids. PD

John Hibma

Nutritionist

Central Connecticut Co-operative Farms Association