The recent hike in feed ingredient prices, at a time of moderate milk prices, has dairy producers and their consultant teams focused on ways to protect their income over feed cost (IOFC). With dairy farms utilizing more corn silage as the majority of their forage base in milk cow rations, the increases in market prices for the key protein ingredients have assumed greater significance in dairy farm feed budgets.

Dairy producer teams are looking to lower lactating dairy cow ration crude protein contents – more accurately the ration nitrogen (N) content – while maintaining or even improving milk component yield. The primary driver for this approach is to decrease off-farm purchased protein feed costs while improving ration N utilization.

A secondary, but not insignificant, benefit is the reduction of N excretion into the farm environment, with potentially fewer acres needed for manure application. A third benefit is the lowering of ammonia emissions from the farm, which is an air quality concern.

Nitrogen (N) use and efficiency in the lactating dairy cow

The N intake of lactating dairy cows is used for milk and milk protein production, or excreted via feces and urine. Milk-N efficiency (MNE) is an index that can be used to assess the efficiency of N use on dairy farms. It is simply the ratio of N secreted into the milk divided by the intake of ration N.

For everyday use on dairy farms, the pounds of true milk protein output can be divided by the pounds of ration CP intake. (This quick and simple method does not contain all the milk N fractions and will give a slightly lower MNE value using the milk true protein versus the milk total protein content. However, it is the milk true protein number that is more readily available on the farm).

For example, a herd averaging 85 lbs daily in production at 3.0 percent true milk protein content with an average intake of 60 lbs TMR dry matter at 17.7 percent CP has an MNE of:

85 x [0.03/60] x 0.177 ≥ 2.55/10.62 ≥ 24.0 percent.

In this example, the MNE value of 24.0 percent is on the low end of the typical range (20 to 38 percent). The implication from this example is that more than 75 percent of the ingested N is excreted in the manure. Not good for the pocket book nor the farm’s nutrient management plan.

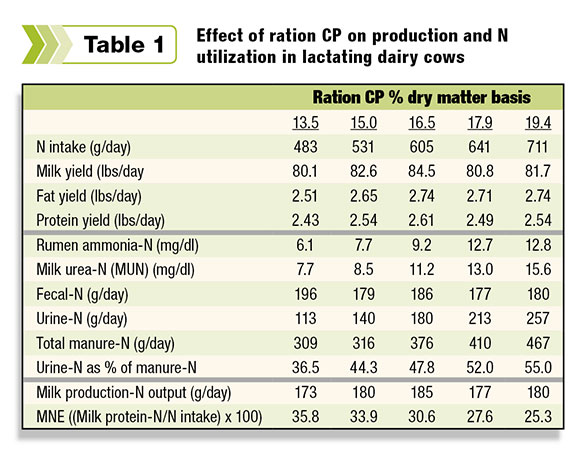

Does the ration CP content of 17.7 percent need to be that high? What’s the relationship between ration CP and MNE? A comprehensive research trial looked at milk production, N utilization and MNE with lactating dairy cows fed TMRs from 13.5 to 19.4 CP on a dry matter (DM) basis.

The TMRs contained the same ingredients and forage-to-grain ratios; the change in ration CP (in approximately 1.5 percent CP increments) was made only by swapping solvent-extracted soybean meal for

high-moisture shell corn on an equivalent DM basis.

There was no significant difference in dry matter intake (DMI) between the five ration CP treatments.

The results are summarized in Table 1 . From this table it can be seen that:

• Moving from 13.5 percent to 19.4 percent ration CP content did not significantly increase milk production or milk protein yield (also expressed as milk protein-N output).

• Trends in rumen ammonia-N and milk urea-N values tracked similarly, so MUN values could be a proxy for monitoring waste or overfeeding of ration CP.

• As ration CP increased, total manure-N output increased. However, even with increases in ration CP, the fecal-N output remained relatively constant. Conversely, with higher CP rations, excess N is excreted via the urine and this can be as high as 50 percent of the total manure output.

• Higher CP rations were less efficient (MNE) in the transfer of ration N intake into milk protein-N.

While the data in Table 1 shows the lowest urine losses and highest MNE at a ration CP of 13.5 percent (dry matter basis), an optimizing analysis showed the optimal for milk yield and milk protein yield, (and hence IOFC) to be 16.7 and 17.1 percent, respectively.

It should be noted that the ration CP adjustments in this trial were made using solvent-extracted soybean meal, a relatively rumen-degradable protein source.

Low CP rations for lactating dairy cows in practice

Application of recent advances in protein nutrition using the Metabolizable Protein (MP) system (based on digestible microbial protein supply, digestible rumen-undegradable protein (RUP) supply and supplemental rumen-bypass amino acids (AA) to the small intestine) have allowed researchers to focus more on MP per cow, using lower CP rations on commercial-type herds.

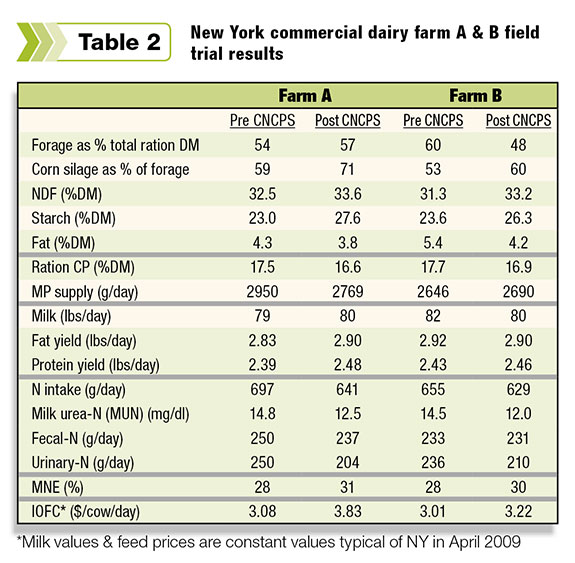

One such study was conducted on two commercial dairy farms (identified as A & B) in New York for an eight-month period.

Using the Cornell Net Carbohydrate and Protein System (CNCPS v6.1), in conjunction with the nutrition consultant, the initial herd rations were evaluated, and mutually agreed changes implemented over an eight-month period.

The results pre-CNCPS and post-CNCPS changes are shown in Table 2 . From this table it can be seen that:

• Using CNCPS, the ration CP contents were reduced by approximately 1.0 CP unit, with MP supply decreased in Herd A, and MP supply about the same in Herd B.

In conjunction with this, there are reductions in both MUN and urine-N loss, reflecting improved N utilization and less N excreted.

• There was an increase in milk protein yield (better for Farm A), which was attributed to less ration fat content and an increase in ration starch levels. This emphasizes again the link between rumen-fermentable energy and of the rumen-degradable protein (RDP) in relation to microbial protein synthesis.

• The MNE on both farms increased by 2 to 3 percentage units and the IOFC was significantly improved for both farms, ranging from +22 to +75 cents per cow daily.

These types of on-farm studies emphasize the key steps needed by the nutrition consultant and the farm team to ensure successful application of this process.

1. Is the producer herd a candidate for this approach? Are milk cow ration CP’s more than 16.5 percent (DM basis) and are bulk tank MUNS more than 12 mg per dl? What is the current MNE of the herd? Is there “buy in” from the farm team to implement change?

2. Does the nutrition consultant use up-to-date dynamic ration formulation software (like those based on CNCPS) to allow for these types of calculations?

3. How consistent are the forages? Is the forage analysis suite used sufficiently comprehensive to describe all the forage characteristics for input into dynamic ration formulation software? Are forage dry matters (DM) checked and updated daily? Are there many forage changes in the upcoming months?

4. Are the rumen-fermentable energy sources characterized analytically for key physical and chemical parameters (i.e., kernel processing, mean particle size of grist, rumen-available starch, etc.) so the correlating rumen responses fall within expectations?

5. Can the herd be fed on a group basis to target more productive rations to fresh and early-lactation cows?

6. For TMR-fed herds, are the loading, mixing and TMR feedout management procedures all consistent? Is the management team confident that the formulated ration will not be disabled by variation in TMR utilization (i.e., undermixing, overmixing, inconsistent feedout along the bunk or cow sorting)?

7. How will the nutritionist and farm team monitor progress? (i.e., milk yield, milk component content, milk component yield, MUN and MNE), and over what time period?

In practice, regular monitoring of bulk tank MUN is a good proxy for the changes along with milk protein content and yield plus calculated MNE. The subset of high-producing commercial herds (75 to 116 lbs daily) from a recent survey has shown excellent milk protein content and yields with MUN values ranging between seven to 10 mg per dl.

The average ration CP content was 15.6 percent (DM basis), supplying 2,700 grams of MP per milk cow daily. The calculated MNE for this subset in the survey ranged from 28 to 38 percent.

Despite some challenges, the potential gains in milk protein yield, improved IOFC and less urinary-N excretion are all now realizable. The unpredictability of both the milk price and the feed ingredient market highlights the wisdom of using ration N efficiently and economically. PD

The author gratefully acknowledges data and input from Dr. Larry E. Chase, a professor and extension specialist in dairy nutrition at Cornell University in Ithaca, New York, in the preparation of this article.

References omitted due to space but are available upon request. Click here to email an editor.

Tony Hall

Dairy Technical Service Manager

Lallemand Animal Nutrition