“Our cows are only as productive as the forages we produce for them.” There is nothing closer to the truth than this quote by a dairyman a few months ago. Forages are the foundation for high-producing dairy rations and often determine the level of top-end milk potential.

Furthermore, no other single entity is more indicative of marginal dairy profitability than forage quality. Alfalfa haylage quality can be measured by relative feed value (RFV) or relative forage quality (RFQ), but corn silage value and quality can be a bit more difficult to quantify due to its multi-component composition of both fiber and starch.

One thing is for certain, kernel processing score (KPS) plays a fundamental role in determining how the corn silage will feed throughout the year.

Most dairy producers and custom harvesters have heard of the importance that adequately processed corn silage can mean to milk production and a profitable year. But do we fully understand the true significance?

While planning for this year’s harvest, it is important to go through a checklist to ensure we achieve our goals for well-processed corn silage. Beginning several weeks prior to harvest season, review and inspect equipment following a similar checklist:

- Start at the front of the machine and work your way through the crop flow. At the cornhead, make sure the knives are in good condition and sharp enough to make it through the season.

- Make certain that the scrapers, crop guides and feed rolls are in good working condition and are correctly adjusted or replaced if worn.

- Make certain the shear bar is square.

- At the cutterhead knives, a daily inspection for damage from rocks along with daily sharpening to use minimal horsepower is warranted.

- The kernel processor does most of the work processing the grain, so it is of utmost importance to measure the gap setting to make sure it is even and accurate. Look for rock damage.

Bottom line: Inspect, adjust and replace parts, if warranted. Consult with your trusted forage equipment specialist for additional points of inspection and specific recommendations prior to and during harvest.

For today’s high-producing dairy cows to optimally digest the corn grain in whole-plant corn silage, the corn kernels must be optimally processed. This is no less critical than the micron size of dried corn or other starch sources (grains) included in a TMR for enhanced availability and digestibility.

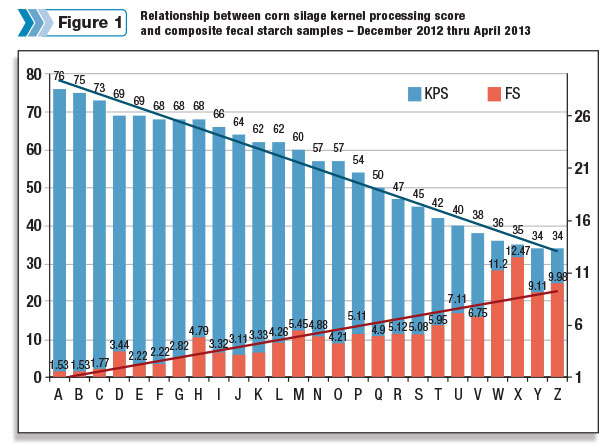

Our company’s regional account managers have collected and summarized field data demonstrating that higher KPS of corn silage increased total tract starch digestibility (TTSD) of starch due to reduced fecal starch (Figure 1).

The reduction in fecal starch results in improved efficiency of starch utilization from the TMR. Specifically, Dr. Jim Ferguson at the University of Pennsylvania demonstrated that a one-unit change in fecal starch equals the energy equivalent for 0.72 pounds of milk production.

Bottom line: If improved kernel processing reduces fecal starch from 5 percent to 1.5 percent, there is energetic potential for an additional 2.52 pounds of milk from the same corn silage.

Dr. Dave Mertens, formerly of the U.S. Dairy Forage Research Center, developed the laboratory methodology to evaluate corn silage kernel processing. Basically, a corn silage sample is dried and shaken or tapped through a series of nine screens.

The portion of the sample that passes through a 4.75-mm screen is collected and analyzed for starch as a percentage of the total starch in the corn silage sample. The resulting percentage is KPS. To put 4.75 mm in other terms, approximately 1/12th of a kernel will pass through the screen, and that is about the same diameter as a 3/16-inch drill bit. Dr. Mertens also proposed guidelines for interpreting the results that are still in use:

- Optimum – greater than 70 percent

- Adequate – 50 to 70 percent

- Inadequately processed – less than 50 percent

Bottom line: In order to minimize fecal starch and maximize energetic efficiency, corn silage KPS should be above 70 percent.

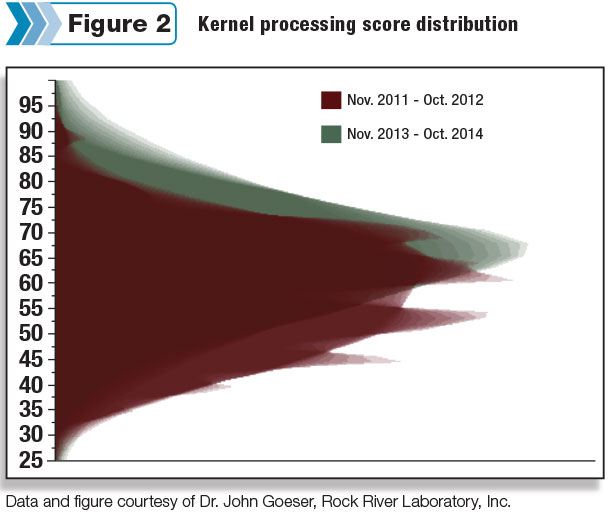

From processor roll speed differentials to completely different processor designs, the dairy industry’s heightened awareness of KPS and its importance is gaining momentum, but there is still considerable room for improvement.

Recent analysis of corn silage samples submitted to Rock River Laboratory Inc. yielded a general improvement in KPS over a two-year period without significantly altering the distribution or variation (Figure 2). Thus, we are improving the average KPS, but ideally we should be skewing the distribution toward higher KPS, as well.

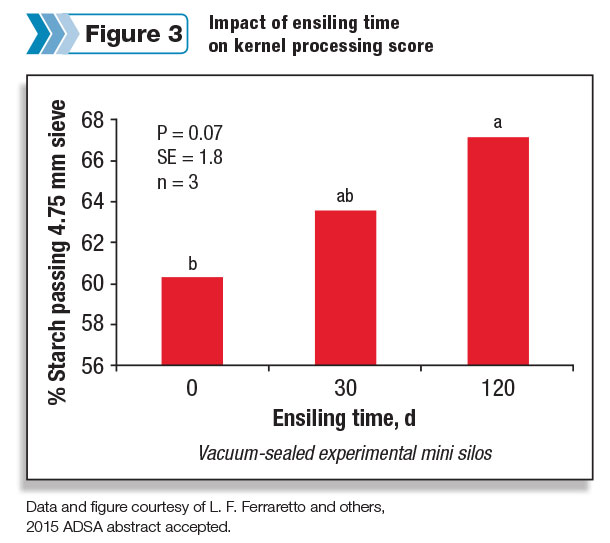

Although harvest is still the most critical time to impact KPS, we also know that KPS improves over time due to fermentation in the pile or bunker. Recently, Dr. Randy Shaver’s research team at the University of Wisconsin has investigated the effect of ensiling (fermentation) on KPS in whole-plant corn silage harvested with varied processors and settings.

Dr. Shaver’s research team conducted two experiments to evaluate the impact of ensiling on kernel processing score of whole-plant corn silage (WPCS) of varied processors and settings, and extended ensiling times on KPS of corn silage.

In the first study, fermented corn silage had KPS that was 9.9 percentage points higher than the unfermented samples collected at harvest (60.1 percent versus 50.2 percent; P = 0.01). In the second experiment, the samples fermented for 120 days (P = 0.07) tended to have KPS that were 7 percentage points higher than the unfermented samples collected at harvest, but this difference was not observed after only 30 days of fermentation (Figure 3).

Our field trial data has also confirmed an 8 to 12 percentage point increase in KPS from harvest through fermentation with greater gains in KPS observed among samples with the lower KPS at the start.

Bottom line: In storage and during fermentation, KPS will improve anywhere from 5 to 15 percentage points depending on KPS coming out of the harvester and time in storage.

Take-home message: Follow a checklist to make sure equipment is in good working order and adjusted properly, which should increase KPS coming out of the harvester with further increases due to fermentation in storage, ultimately leading to improved energy efficiency due to reduced fecal starch and potentially more milk. PD

Kory Duerst is the cattle regional account manager with Chr Hansen Animal Health and Nutrition. He can be contacted by email. Keith A. Bryan, Ph.D., is the technical services manager for North and South America for Chr Hansen silage inoculants and ruminant DFMs.

PHOTO: Photo by Lynn Jaynes.