Dairymen can’t catch a break. Reports are that there will be a bumper corn crop in 2009 and prices will remain tolerable.

However, the downside is that much of the crop could be contaminated with harmful levels of mycotoxins.

Weather conditions across the grain-producing areas of the U.S. favor the growth of mycotoxin-producing molds. Cool, damp conditions, particularly during flowering (tasseling of corn, blooming of small grains, etc.), are known to increase the populations of certain field molds (Fusariums) and the mycotoxins they produce. Consequently, DON (Vomitoxin), AcDON (acetylated DON), other trichothecenes, fumonisins and zearalenones (fusariotoxins – mycotoxins produced by Fusarium molds) may be found at levels which can impair cow health and performance. Aspergillus molds, which produce aflatoxins, do well in higher temperatures and lower rainfall.

Cool, damp weather conditions experienced in the Mid-Atlantic earlier in 2009 prompted The West Virginia Department of Agriculture to issue a warning that wheat and barley produced in the Mid-Atlantic region could be contaminated with DON and other fusariotoxins. The warning was issued because significant field outbreaks of Fusarium molds on wheat and barley were found. Significant levels of DON and other fusariotoxins can occur when these molds flourish. Livestock producers were advised to keep a close eye on their animals when feeding home- grown grains. As might be expected, milling byproducts from grains grown in the same region may also be high in mycotoxins.

Variability in the development of corn across the Corn Belt also bodes for a year with a greater-than- normal occurrence of mycotoxins. Abnormally cool, damp weather persisted even into early August, where in the upper Midwest many fields had just started tasseling. The Office of the Texas State Chemist published reports (for corn analyzed through July 27) giving the levels of fumonisins and aflatoxins found in corn harvested in several south and central Texas counties. Nearly 50 percent of the samples were contaminated with mycotoxins. Aflatoxin levels ranged from 20 ppb to 938 ppb and fumonisins ranged from less than 0.2 ppm to 3.7 ppm in the samples collected. Obviously, much of this corn should not be used in lactation rations.

What does all this mean? Be prepared! Aflatoxins are the only mycotoxin regulated because they present a human health hazard (carcinogenic), even when fed to animals. Dairymen know that cows fed rations with 20 ppb or more of aflatoxin will produce milk that violates the maximum allowable for the aflatoxin metabolite, M1 (0.05 ppb), and the milk will be dumped at the dairyman’s expense. In contrast, fusariotoxins are not regulated but still can be very toxic to cows. It therefore falls to the dairyman to be aware that these mycotoxins and even aflatoxins may be in their feed ingredients, especially home-grown feedstuffs.

Recognizing when poor health and performance is being caused by mycotoxins is extremely difficult. Some mycotoxins, such as Zearalenone, predominantly affect reproduction and are relatively easier to identify. Also, high levels of mycotoxins that cause acute physiological signs and dramatic changes in milk production and animal health can usually be identified with some sleuthing. Unfortunately, the most common and most difficult mycotoxin challenges to identify occur when rations contain low levels of mycotoxins and all of the health effects are subclinical. In this case, subtle increases in ketosis, retained placentas, displaced abomasums, mastitis, elevated SCC (somatic cell count), metritis and/or lower milk production can go as just “normal” fresh cow problems. But in fact, they may be due to cows consuming rations containing low levels of mycotoxins. Subclinical mycotoxicoses drain profitability by lowering milk production and milk quality, increasing expenses from inappropriate veterinary therapies, decreasing efficient use of labor and other resources and more.

Attention to key details and knowing how to manage a mycotoxicosis is a must. Two practices should be considered when the mycotoxin risk is high: (1) analyzing the feed (2) using an appropriate product to counteract mycotoxins. Analyzing for mycotoxins is a place to start, but a negative result (mycotoxins not found) should not be totally reassuring. Mycotoxins are not evenly distributed in feedstuffs, and the one-pound sample submitted to the lab represents the entire lot of feed. Proper sampling is imperative. A positive analytical report, however, identifying the mycotoxins found, allows the producer either to completely eliminate the feedstuff or, if that isn’t possible, to minimize its use in rations.

Whether an analysis is done or not, knowing the types of products that are most effective against a known or suspected mycotoxin problem is useful information. Products are generally divided into two main types – mycotoxin “binders” (adsorbents), and mycotoxin “deactivators.” The term binder is commonly applied to all products because binders were the only products available for many years. Mycotoxin deactivators are newer technology whose effect is to chemically deactivate mycotoxins. Some products on the market combine these two technologies and contain both a binder and a deactivator component.

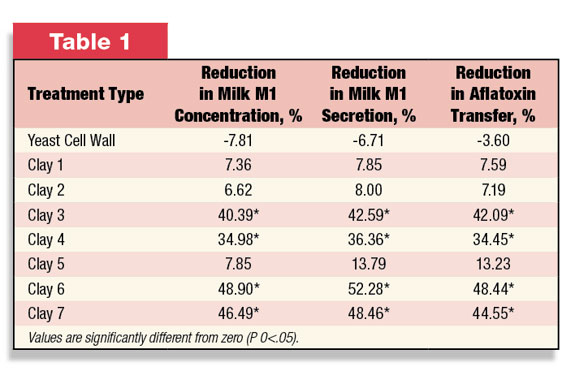

Typically, binders are either clays (mineral adsorbents) or yeast cell wall products or combinations of both. Binders can only bind mycotoxins that have suitably located polar groups, essentially aflatoxins and to a lesser degree, fumonisins. Bound mycotoxins are then unavailable to do damage in the rumen, or be absorbed from the gut into the bloodstream to do more damage or enter milk but pass out in the feces. It should be noted that not all binders are equal in their ability to bind “polar” mycotoxins (Table 1). Some homework should be done to identify the good ones. Binders tend to cost less to feed but price is not the only feature to be considered. The value received should justify the price. For example, yeast cell wall

products are promoted to bind mycotoxins in a manner similar to clays; however, research indicates that they may be less effective in their ability to reduce M1 (Table 1). Binders are the product of choice when aflatoxins and/or fumonisins are the mycotoxins of concern.

Mycotoxin deactivators work by enzymatically altering the molecular structure of trichothecenes and zearalenone. Trichothecenes and zearalenone do not have suitably located polar groups and little to none can be bound; therefore, binders are not products of choice to manage these mycotoxins. However, these toxins do have molecular structures that can be altered by specific enzymes (deactivated) to produce nontoxic end products. For example, all trichothecenes have a particular ring structure that can be enzymatically broken, making them nontoxic. Similarly, the ring structure of Zearalenone can be altered enzymatically, changing its shape such that it no longer mimics estrogen and allows for the return of normal reproductive processes. Mycotoxin deactivators are products of choice when DON, other trichothecenes and zearalenone are the mycotoxins in the feed and are affecting animal health and performance.

Mycotoxins are somewhat like Forrest Gump’s box of chocolates… “You never know what you’re going to get.” There are always multiple types of mycotoxins present in any contaminated feedstuff. Fusarium molds are known to produce an array of mycotoxins, not just DON. However, DON is considered a “marker” because when DON is found there is a high probability that other trichothecenes also are present at some level. The consequence of having multiple mycotoxins in the feed is that they act additively or synergistically to increase the severity of the mycotoxicosis. This is why products that contain both a binder and a deactivator are the most effective in managing mycotoxin challenges.

While there are no hard and fast rules, aflatoxins are encountered more commonly in drought-stressed crops in hot weather; conditions which can occur in the Midwest, but occur more frequently farther south and in the central valley of California. Conversely, trichothecenes and zearalenone are more frequently encountered throughout the Midwest, Northeast, Canada and other regions with more temperate climates. Weather conditions contribute to the severity of mycotoxin outbreaks in different locales while cropping cultural practices, such as no-tilling, also contribute to a higher incidence of the various mycotoxins. Of the mycotoxins that are found in feeds, approximately 85 percent are present in the crops at harvest.

It helps to understand the broad effects of mycotoxins on the health of dairy cows. One of the first effects mycotoxins have on dairy animals is to impair the immune system. A slight increase in SCC may not seem like much, but it may be an indication that the cow’s immune system isn’t up to par, but she is trying to fight off a potential intramammary infection. Similarly, retained placentas are related to the effectiveness of the cow’s immune cells (neutrofils) in expelling the placenta. Other signs of an impaired immune system are non-responsive metritises, inadequate responses to vaccines, and other problems. Mycotoxins are not the only thing that can affect the animal’s immune competency, but they very often play a role.

Mycotoxins (aflatoxin, DON and other trichothecenes) reduce feed intake and feed utilization. Many mycotoxins can have antimicrobial properties and reduce the bacterial populations in the rumen. Feed efficiency, feed intake and nutrients available for milk production and other functions declines.

Indications are that the 2009 crop will yield an abundance of corn. Indicators also point toward more of the crop being contaminated with mycotoxin. While mycotoxin- contaminated feeds may be impossible to avoid, contaminated feeds may be used when the mycotoxins present are known and steps are taken to manage the contaminant either by limiting the contaminated feed used and by using a product that effectively counteracts the mycotoxins. PD

R. Mike Watkins is a technical manager withBiomin, USA Inc. Email Mike Watkins.