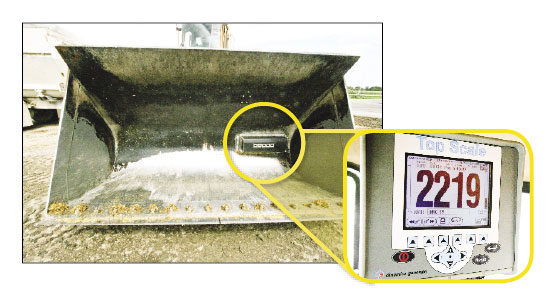

Research by Dr. David Mertens, formerly of the U.S. Dairy Forage Research Center and now retired, indicates that a rain event in a bunker silo can affect milk production by up to 6 pounds of milk per head. On a 1,600-cow herd, that can total 8,000 pounds of milk. If moisture in the rain-soaked feed could be adjusted more easily, a more consistent diet could be maintained. The dg precisionFEEDING System intends to do just that. It includes an NIR feed analyzer that can be mounted inside a payloader bucket. The NIR reads the dry matter content of forages and grain when the feed is placed in front of the infrared sensors, and also measures protein, starch, ADF, NDF, crude fat and ash values.

The feed analysis is sent to one or multiple PCs loaded with feed management software, which upon calculation, wirelessly sends new instructions to a high-tech weighing controller that adjusts the amount of feed that enters the TMR by weight.

“This idea is the next step in feeding to provide a more consistent diet day-to-day,” says Dana Allen, PhD., partner at Gar-Lin Dairy Farms in Minnesota.

It was developed by Dinamica Generale of Italy, which has studied, developed and produced weighing systems for agricultural machines and mixer wagons for two decades. In 1999, the company started the feasibility study for the project IRM: Intelligent Ratio Management. Its scope was studying and developing an analyzer able to work in as harsh of an environment as a mixer wagon for measuring in real-time nutrients of ingredients, reports Alberto Barbi of Dinamica Generale.

The first preseries was studied for mounting on mixer-wagon conveyers for the European market. Therefore, the current system can be adopted for use on belt conveyors and is marketed as such under the brand name FeedScan by Engineered Storage Products Company of DeKalb, Illinois.

Precision feeding offers dairy producers a better way to monitor feed inventories and help manage feed costs, especially by avoiding overfeeding or underfeeding of ingredients, states Matt Dobberstein of Dinamica Generale U.S. sales and marketing.

“For the feeder it provides the benefit of having an analysis right at the same time as feeding, which is a time savings,” he says, noting the sample doesn’t have to be carried to a nearby building.

By ensuring consistent dry matter amounts, cows will receive more consistent feed and have better rumen function, hopefully resulting in increased milk production and fewer feed refusals.

Results from European trials were feed cost savings up to 20 percent, milk production up two percent, consistent rumen pH and reduced manure and methane output, reports Andrea Ghiraldi with Dinamica Generale.

Dobberstein adds that based on those trials it was determined the technology works best for herds with 200 cows or more.

One dairy herd in Minnesota has taken the equipment for a test run.

Gar-Lin Dairy Farms, a 1,600-cow operation, started using this system in June as part of a trial conducted by Dr. Noah Litherland, assistant professor of dairy cattle nutrition, research and extension at the University of Minnesota. The herd’s daily ration consists of corn silage, haylage, high-moisture corn (25 to 30 percent moisture), corn gluten feed, soybean meal, bypass fat, bypass protein, tallow and a vitamin package. The feed protein level is at 17 percent. For the study, the dairy is feeding 500 cows in two paired pens based on stage of lactation, number of lactations and days in milk.

“We thought it was an opportunity to get a better handle on moisture levels in the feed,” Allen says. “With outdoor feed storage on the dairy, any rain event subjects the feed to a dry matter change, and those ration adjustments can be difficult to make throughout the day.”

She notes the scanner fits right in the payloader bucket, is easy to use and the software is easy to navigate. However, Allen is waiting to see how the cold winter weather may affect its performance.

Results of the study are not expected until December, but one rainfall event of six to seven inches in September showed the technology’s bang for its buck. The cows fed with precision recovered faster than the cows that were fed with the farm’s traditional methods. Also, since they’ve been using the system, she’s seen a more consistent feed refusal from the pen being adjusted, at least by the naked eye.

The farm is waiting to see the official results of the study before it makes a purchase decision on the equipment, but Allen says they are interested in keeping the equipment on the farm.

With any change, it can take awhile to adapt to the new system. The feeders had to adjust to taking the reading with the feed in the bucket and then waiting a minute or two for the adjustment to be calculated. As the farm’s nutritionist, Allen also had to adjust to the new software and NIR equations used.

“Change can be difficult,” she says, “but it’s more important in the long run to provide the best diet possible to the cows.”

The long-term effect of this system could be more consistent herd health, better rumen efficiency, cows not going off-feed, the prospect of pushing the cows harder and possibly more milk with less feed, Allen says.

The feeding system costs $60,000 to $70,000 for the entire kit, which includes DTM professional feed management software, an IRM (Intelligent Ration Management) NIR feed analyzer, a remote control and the Top Scale, a high-tech weighing controller that wirelessly receives data from the NIR analyzer. The price also includes installation, service for the first year and calibration adjustments. PD

For more information on this feeding system, contact Matt Dobberstein at dg-usa@dinamicagenerale.com , visit your local Harvestore dealer ( www.harvestore.com) or call (815) 756-1551.

YOUR RESULTSWould you benefit from precision feeding? The following checklist can be used to determine if this new technology might be a fit for your operation.

1. Do you have 200 cows or more?

2. Do you use a bucket or belt conveyor to transport feed?

3. Is your feed storage exposed to rain or snow?

4. Would it be helpful to know the moisture level of your feed ingredients?

5. Are you interested in reducing feed costs?6. Is consistency something you strive for in your feeding system?

7. Do you want to reduce the amount of feed refusals you collect?

8. Would you like to increase the feed efficiency of your cows?

9. If you could increase milk production two percent, would you?

10. Would you like to run an NIR analysis without exiting the cab? If you answered yes to seven or more of these questions, this technology may be one for you to consider.

PHOTOS :

This payloader bucket at Gar-Lin Dairy Farms in Minnesota is mounted with an NIR analyzer to measure dry matter content of forages and grain, as well as protein, starch, ADF, NDF, crude fat and ash values. Readings from the NIR analyzer are automatically calculated with the ration balancing software and adjustments are sent wirelessly to this weighing controller for the precise amount of feed that needs to be added to the mixer. Photos courtesy of OPEN ROADS.

-

Karen Lee

- Midwest Editor

- Email Karen Lee