Cow health is perhaps the most critical aspect of every dairy operation. Optimizing cow health not only optimizes production performance of the dairy, it helps ensure quality milk is produced by cows with reduced health issues and increased reproductive performance.

For years, the industry has been conditioned to think that improvements in the dairy operation require greater investment – not only related to cost, but to labor. But not all technology should be viewed this way, and especially not the evolving technology that nutritionists have available today to help improve their clients’ herd health and production efficiency.

Focus on longevity and health of the cow is paramount to rumen health and allows producers to achieve a healthier, more productive cow. One method is the new Calibrate technology. This technology measures both starch content and ruminal starch availability from ration ingredients.

Maintaining optimal rumen health requires monitoring and adjusting the extent of starch degradation in the rumen. It can be easy to overdo starch availability in the diet.

In doing so, not only does that make the cost of the ration unnecessarily higher – given current corn prices – but also can lead to subacute ruminal acidosis (SARA), acidosis, sore feet and lameness. Conversely, low ruminal starch availability leads to under-performance – cows simply milk less.

Through testing, feed ingredients can be evaluated in the system for both ruminal starch content and digestibility. Subsequently, the ingredients are assigned a GPN index value. This value accurately predicts how the starch will be digested in the rumen.

The optimal rumen starch digestion level is known based on extensive animal research data. Knowing this, these values can then be entered into the system’s nutrition model and balanced for the herd’s optimal ruminal starch digestion level.

Each producer has different goals. Especially with the high price of corn, some producers logically want to reduce the corn levels in the diet to ultimately cut costs.

Other producers want to maintain inputs but more finely tune secondary benefits of rumen health, like improving herd health, eliminating SARA or even replacing corn with another byproduct at a similar inclusion rate.

Red Rock Dairy in Amherst, Texas, now milking 2,400 cows, was one of the first herds to field test this new ration balancing technology in the Southwest, but the biggest test for the technology came after its commercialization.

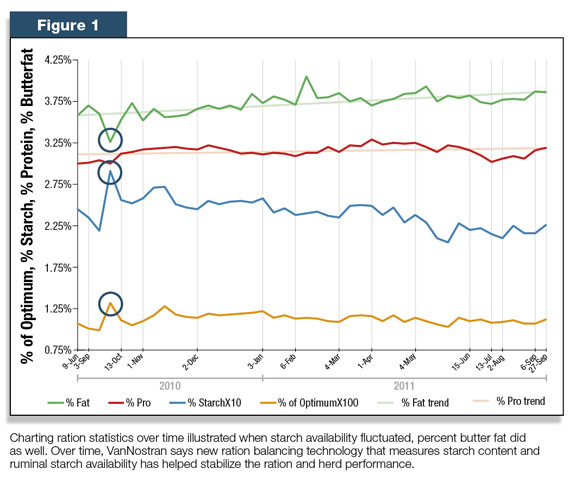

In September 2010, the herd at Red Rock, much like other dairies in the U.S., experienced a drop in milk butterfat and protein. Immediately, the ration ingredients were tested with the technology’s analysis for starch content and GPN.

It was found that a recent change in feed ingredients showed the ration was delivering over 130 percent of the optimum level of ruminally digested starch, delivering way too much digested end products to the cows and thus suppressing the butterfat.

Making adjustments using the technology’s ration modeling, the herd’s butterfat returned to normal or acceptable levels. (See Figure 1 .)

“We had tried to use wheat and barley in the ration because the price was good,” notes Johnny Van de Pol, manager of Red Rock Dairy.

“We thought it was a good buy, but it obviously was not once we saw the response.After testing, we were able to back the herd out of these rapid starch ingredients and get them back to our herd optimal level.”

Through ongoing ration testing, it was determined that the optimum level for Red Rock Dairy is at 110 percent of the rumen digestible starch target. It is at this level they feel they get the best cow health and performance.

And, at this level, it helps manage the incidence of subclinical rumen acidosis, which has been very important to Red Rock Dairy.

“The numbers all match up to what we are seeing in the cows,” adds Van de Pol.

With changing and evolving demographics in the dairy industry, more and more producers now want to know what the various fees and services associated with their nutritional counsel are so they can choose what is best for them.

“I think the higher the feed costs get, the better investment this software becomes,” says Van de Pol. “It helps us make sure we are not overfeeding or underfeeding in a particular area. And, it gives us a better idea how the ration is going to react within the cow before we even feed it to her.” PD

Mountain States Consulting , located in Clovis, New Mexico, offers nutritional counsel to Southwestern dairymen. For more information on their use of the ration balancing technology discussed in this article or to discuss herd ration analysis, visit www.mtnstatesconsulting.com .

-

Will VanNostran

- Nutritionist

- Mountain States Consulting

- Email Will VanNostran