Get ready: corn silage in 2017 is not going to be typical corn silage. Illinois growing and harvesting conditions may reflect your situation and corn silage quality. Test, test and retest will be a common theme.

The following conditions occurred in Illinois:

- High-quality corn silage with over 200 bushels per acre exists.

- Drought has caused some corn silage to be short, stop growing or contain no ears.

- Wet planting conditions in May delayed planting or caused replanting of flooded acres.

- Excessive rain in July resulted in corn under water (from 1 foot to total rot).

- Mycotoxins could be a risk due to heat stress or wet conditions.

Listed below are a number of questions that should be considered when you begin feeding the 2017 corn silage crop.

If my corn silage is high-quality with minimal stress, what should I be checking?

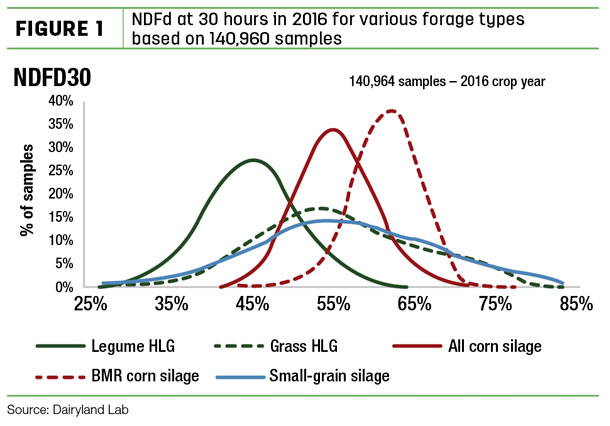

Test your corn silage for starch content (target over 30 percent), 30-hour neutral detergent fiber digestibility (could be over 55 percent, over 65 percent for BMR) and 30-hour undigested neutral detergent fiber (could be under 45 percent for non-BMR).

Higher levels of starch and neutral detergent fiber digestibility (NDFd) will provide more energy and microbial growth (Figure 1).

Higher undigested neutral detergent fiber (uNDF) values could limit dry matter intake and rate of passage.

Another test is a kernel processing score, which reflects availability of starch in corn silage (target a value over 70 percent). If values are under 70 percent, your cows are not using all the starch in the corn silage efficiently.

Conducting a fecal starch test can also reflect starch utilization, which should be under 5 percent. Fecal starch could be from corn silage, corn grain or other starch sources.

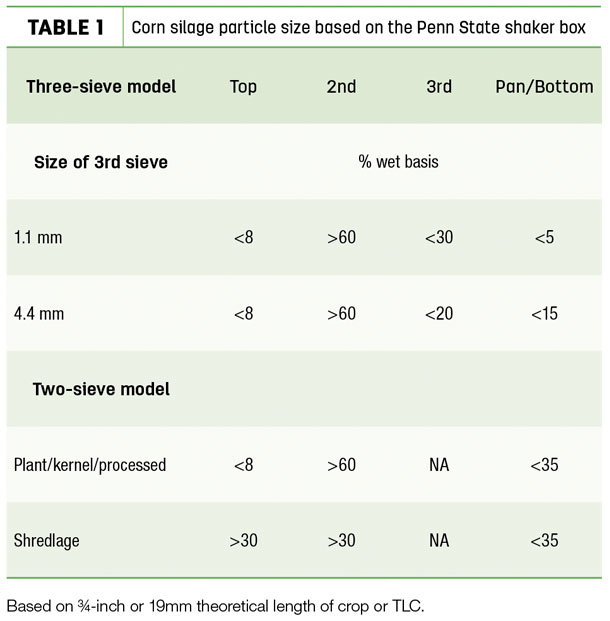

Corn silage particle size can also be evaluated using a Penn State particle box. Guidelines are listed in Table 1 for kernel- or plant-processed corn silage and shredlage-processed corn silage.

If your corn silage was processed as shredlage, the top two boxes will be compared to the top boxes with corn silage plant processing.

If my corn silage was heat-stressed or impacted with drought, what can I expect?

Depending on the stage of maturity when heat stress or drought occurred, dry matter yield will be reduced. Nutrient-wise, starch content can be lower due to poor pollination or unfilled cobs. Starch content could also be normal if a cob formed with a shorter plant and lower yields. Wisconsin researchers suggest the energy content can vary from 85 to 100 percent of normal corn silage.

Aflatoxin could be a risk due to the stressed corn plant. Milk processors may be testing for levels of aflatoxins in milk, which may provide an early indicator of contamination before it causes herd health problems. Flow agents or commercial products can be added (clay-based products are more effective) or diluting the at-risk corn silage with other feed ingredients.

If corn silage is immature at harvest due to late planting or early frost, what risks could be occurring on my farm at feeding time?

Immature corn silage will be similar to feeding a grass-type forage with higher levels of sugar and protein, while starch can be low.

Dry matter content can be over 70 percent, depending on harvest strategies. Ideally, allow the corn plant to reach over 30 percent dry matter to improve fermentation and add a research-approved silage inoculant. If the corn is green at a killing frost, delay harvest to allow the plant to dry down before chopping. Chopping several stalks may provide a benchmark for when to begin chopping.

Could nitrates could be a risk?

Drought-stressed corn silage or immature corn silage that was frost damaged could have higher plant nitrate levels as the roots continue to absorb soil nitrates, and the green plant material, such as leaves, do not convert the nitrates to protein and other nutrients.

A favorable fermentation during storage can reduce corn silage nitrates by 30 to 50 percent. Greenchopping or pasturing these corn plants are higher risks for nitrate toxicity. Testing corn silage after ensiling is recommended if your corn silage was at risk for high levels of nitrate.

Are mycotoxins a concern?

As noted, drought-stressed corn silage could develop aflatoxin. Corn harvested under cool and wet conditions could develop other mycotoxins such as T-2, zearalenone or vomitoxin. Testing is the only way to evaluate if mycotoxin-contaminated corn exists in your corn silage. Check with forage test labs to monitor the level of mycotoxins, as sampling is difficult to get accurate results, and these tests can be expensive.

How long should I wait to feed 2017 corn silage?

Ideally, waiting a minimum of three to six months allows the starch to become more available to break down the protein matrix associated with starch granules. A common term is Christmas corn silage (waiting until after the holidays to begin feeding new-crop corn silage). ![]()

-

Mike Hutjens

- Professor of Animal Sciences Emeritus

- University of Illinois – Urbana

- Email Mike Hutjens