The wet field conditions we saw last year across much of the U.S. have contributed to an increase in fungal diseases – in particular, a rise in the incidence of smut.

Corn smut is caused by the growth of Ustilago maydis, which thrives in conditions of high humidity coupled with plant stressors like poor pollination or damage from insects, weather or equipment.

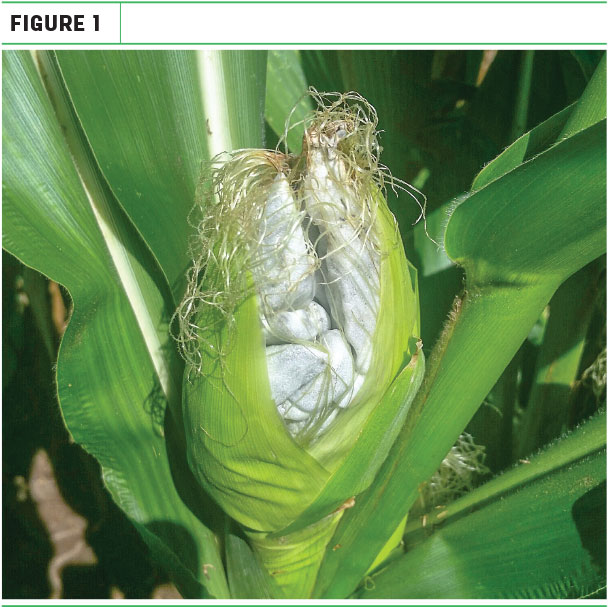

Once the plant is infected, the fungus grows rapidly, leading to large gray galls that contain black spores, typically on the corn ear tip (Figure 1).

The resulting galls decrease grain yield anywhere from 9 to 40 percent. While producers may see a drop in corn yields due to smut contamination, the crop is still nutritionally valuable and can be successfully ensiled. The fungus that causes smut does not produce any known toxins, and studies in sheep have shown that it does not affect feed intake.

In fact, corn infected with smut has a higher content of protein, particularly a higher amount of the amino acid lysine, compared to regular corn.

Nevertheless, feeding silage made with smut-infected corn can decrease feed efficiency, since the fungus uses some of the more readily digestible nutrients to fuel its growth.

Research has shown that total digestible nutrients, net energy for maintenance and net energy for gain decreases the value of corn silage by around 0.5 percent, 0.02 Mcal per gram and 0.02 Mcal per gram, respectively, for each 10 percent rise in smut-infected plants compared to healthy ones.

The nutrient and fermentation profiles of these contaminated silages are likely to be more variable than normal. It’s important to have samples analyzed regularly – at least once a month – so adjustments to the ration can be made as necessary.

When corn contaminated with smut is ensiled, the rate and extent of fermentation can be restricted due to the loss of nutrients because of growth of the smut fungus, which can then predispose the silage to further mold growth and the production of mycotoxins. Treating the corn with a dual-purpose inoculant at the time of ensiling is an important part of the management program.

Dual-purpose inoculants contain strains of both homolactic and heterolactic bacteria to overcome the limitations of using a product that has only one type of bacteria.

During early stages of the ensiling process, homolactic bacteria (e.g., Pediococcus pentosaceus) used in “traditional” silage inoculants convert simple sugars to lactic acid, a strong fermentation acid that leads to a faster rate of acidification, thus maximizing the recovery of dry matter and nutrients, and inhibiting the growth of detrimental microbes.

Homolactic bacteria are very efficient, but natural populations are not as prevalent on the plant material, giving a very strong recommendation for use in an inoculant. However, lactic acid does not have strong antimycotic properties or lead to improvement in aerobic stability (e.g., preventing silage heating during feedout) and are inconsistent when using homolactic bacteria alone.

The heterolactic bacterium Lactobacillus buchneri produces moderate amounts of antimycotic acetic acid. The acetic acid is produced by converting small amounts of lactic acid during the initial active phase of fermentation to acetic.

There is a considerable amount of published research supporting the use of the high application rate of L. buchneri 40788 (400,000 colony-forming units per gram of forage), which reduces or prevents heating and spoilage in a wide range of silages by reducing the population of spoilage yeasts.

Corn smut generally is not an animal health threat but can easily be confused with other corn ear rot fungi that can produce dangerous mycotoxins. Species of aspergillus, fusarium, gibberella and penicillium are most commonly associated with production of mycotoxins that can negatively impact animal health and performance.

There is evidence that smut-infected ears are more susceptible to a secondary infection by fusarium and aspergillus. The smut fungus may not directly produce mycotoxins but can potentially create a window of opportunity for organisms associated with mycotoxin production to cause a secondary infection.

Spoilage yeasts are directly responsible for the majority of heating events in silages. Controlling their growth also has a significant impact on the development of secondary or opportunistic spoilage micro-organisms, especially in silages made from diseased crops.

Yeasts destabilize the silage and raise the pH, allowing molds and bacteria to grow, resulting in spoiled, potentially hazardous feed. A high load of detrimental micro-organisms that come from the field at the time of ensiling means more challenges during feedout.

Last season, there were also higher reports of rust infestation, both southern and common rust, stimulated by the long, wet growing season. Similar to smut corn, the rust fungi utilize nutrients from the plant, reducing its nutritive value and yield, and predisposing it to spoilage, mold growth and mycotoxin infestation.

Researchers at the University of Florida looked at the efficacy of treating rust-infested corn with a dual-purpose commercial inoculant with P. pentosaceus 12455 and L. buchneri 40788.

The study involved a corn crop that was naturally infested in discrete patches in the field at the time of the harvest (Figure 2).

After 97 days of storage, dual-purpose inoculation reduced mold counts in rust silages 80-fold and increased aerobic stability by about 75 percent.

Most importantly, aflatoxin was detected in untreated, rust-infested silage at the level of 5,000 parts per billion – considerably higher than the FDA action level at 20 parts per billion – while there were no aflatoxins detected in the inoculated silage made from the same material.

Well-preserved, stable silages have low pH, driven by lactic acid production by homolactic bacteria plus a good amount of an antimycotic compound, e.g., acetic acid produced by L. buchneri, to prevent the growth of undesirable micro-organisms.

Consumption of low concentrations of aflatoxins by sensitive animals can lead to death in 72 hours; animals that ingest feed contaminated with non-fatal levels of aflatoxins can suffer impaired health, reproductive dysfunction and productivity loss.

In addition to causing palatability issues, reduced animal performance and respiratory problems, molds can produce specific mycotoxins under certain circumstances. Some mycotoxins mimic sex hormones and therefore can disrupt normal reproductive physiology in the cow, leading to problems with conception and abortion, while others can cause serious health issues in addition to negatively impacting performance.

It is therefore very important to implement management practices that will reduce the risk of mycotoxins in your silages.

Corn silage is an important component of the diet fed to ruminants, and feeding poorly fermented or contaminated silages needs to be carefully managed. Take samples properly to obtain accurate test results and find the specific cause of the problem. Use good silage management practices to prevent silage deterioration and to ensure you produce top-quality, hygienic preserved feeds for your herd. ![]()

Bob Charley has a doctorate in applied microbiology from the University of Strathclyde in Glasgow, Scotland. Renato Schmidt has a doctorate in animal nutrition from the University of Delaware and is employed by Lallemand Animal Nutrition as a forage products specialist.

References omitted but are available upon request. Click here to email an editor.

-

Bob Charley

- Forage Products Manager

- Lallemand Animal Nutrition

- Email Bob Charley