Not only does the growth of mold and wild yeast strains in these rations impact the nutritional composition of the diet, they generate heat, which impacts palatability, and certain mold species generate harmful toxins, which impact animal performance.

These micro-organisms are found everywhere, so what can producers do to reduce the impact mold and wild yeast have on dairy production?

To effectively design a mold and wild yeast control strategy, we need to understand the basic requirements for microbial growth. The absence of one of these requirements effectively stops mold and wild yeast growth, thereby precluding nutritional damage of the feed or toxin production by the mold.

Energy and nitrogen sources

The first requirement for micro-organisms to survive and grow is availability of nitrogen and energy sources. Intact grain is a great example of a strategy used to reduce microbial exposure to energy and amino acids inside the grain kernel.

Grain has a cellulose or polyester covering to protect the grain from exposure. While the protective barrier remains, mold growth on grain occurs very slowly, if at all.

Rapid drying of grain may cause the development of cracks or fissures and can reduce the protective barrier, resulting in dry matter loss of stored grain.

Insect damage will also expose starch to mold and wild yeast contamination. Finally, grinding the grain kernels removes the protective coating and exposes the starch, fat and nitrogen to microbes. Grinding grain should be delayed until the time of usage to minimize exposure of the starches to microbial degradation.

Adequate temperature

The second requirement for microbial growth is the environmental temperature. The temperature at which hay, silage or feed is stored often dictates whether mold growth becomes a significant problem.

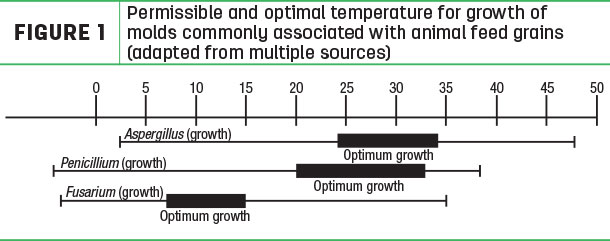

Although molds and wild yeast can respire at a variety of temperatures, significant growth or toxin production has defined limits (Figure 1).

Aspergillus and Penicillium species flourish in warmer temperatures whereas Fusarium molds prefer cooler temperatures.

These optimal conditions also explain why Aspergillus problems are more apparent in warmer climates, but Fusarium incidence is higher in northern regions.

In addition, when feeds are moved from cold storage conditions to warm environments and optimal temperatures, Aspergillus may become a problem even in a cooler climate.

Oxygen for respiration

A third way to control the growth of mold and wild yeast is to exclude oxygen. Like all living organisms, micro-organisms require oxygen to grow and multiply.

Typically, exclusion of oxygen is not a practical way to store grain, but ensiled forages are preserved and stored in oxygen-free environments.

Molds can respire at oxygen concentrations as low as 4 percent. This means the best preservation is achieved by carefully sealing silage storage structures and rapidly feeding the silage after removal from the storage facility.

Free water

The final requirement for metabolism of micro-organisms is available or free water.

Scientifically, water activity is defined as the partial pressure of water vapour above a test sample divided by the partial pressure of liquid water.

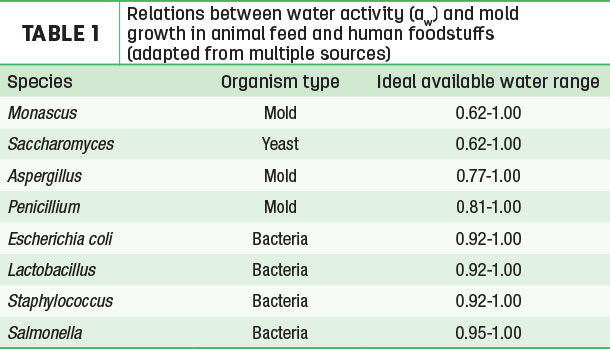

Water activity is measured on a scale from zero to 1 where zero is not available (unbound) water, and 1 is all water is available. Various molds, yeast and bacteria grow best at different available water activities (Table 1).

Some molds and wild yeast, such as Monascus spp. and Saccharomyces spp., can grow at water activities as low as 0.62. TMRs normally range in water activities from 0.50 to 0.94, depending on the water content of forages used in the TMR.

The role water activity plays in mold and wild yeast growth demonstrates the danger of water addition to grains and other feed ingredients. Free water is immediately available for mold growth.

Moisture migration within storage facilities is another source of free water. When grains, feeds and other feed ingredients are warmer or colder than surrounding conditions, moisture migrates and condenses in the bin.

Thus, even though feed or grain may be stored at a safe moisture, mold growth can occur when condensation of moisture occurs.

Control strategies

Elimination of nutrients, cooling grain and feed, preparing an oxygen-free environment and removal of free water are all strategies used by livestock producers to retard microbial growth.

More recently, additives which inhibit the growth of mold and wild yeast are incorporated into forage, grain and other feed ingredients during processing or during feed manufacturing.

Microbial inoculants are bacterial strains that produce a large volume of acid from sugar found in silage.

In 1961, a researcher outlined the requirements needed for a potential silage inoculant: It must be competitive and grow vigorously in the silage, should be homofermentative and produce maximal amounts of lactic acid in a short time, should be acid-tolerant and should be able to grow in material of high dry matter and at temperatures extending up to 50ºC.

The most common species used is Lactobacillus plantarum because this species meets the criteria established. Among the lactic acid-producing bacteria most frequently used, along with L. plantarum, are Enterococcus faecium (which also grows rapidly under aerobic conditions), L. acidophilus, Pediococcus acidilactici and P. pentosaceus.

These lactic acid-producing bacteria drive down the pH of silage, stopping the growth and multiplication of mold and wild yeast.

Lactobacillus buchneri has been studied as an additive to improve the aerobic stability of silages. L. buchneri produces high levels of acetic acid in silage. Experiments in laboratory silos indicated its application at ensiling improved the aerobic stability of silages.

Other researchers have reported L. buchneri improved aerobic stability by fermenting lactic acid to acetic acid. Acetic acid has been shown to be extremely effective at stopping the growth and multiplication of wild yeast strains.

The most effective mold inhibitors are formulated using a combination of antifungal agents, most commonly organic acids and their acid salts. The principal ingredient of most mold inhibitors is propionic acid, which is thought to exert its effects by disruption of the electron transport scheme within the mold.

Propionic acid has a low pH and is corrosive by nature; however, most commercial products are buffered by various salts, making them non-corrosive to both man and machinery.

Because individual compounds have different efficacies against various molds, the inclusion of multiple ingredients in a mold inhibitor can help ensure the broadest spectrum of activity within the feed.

At the concentrations normally used (0.1 to 0.2 percent), mold inhibitors are fungistatic but not fungicidal. Concentrations of 0.5 to 1 percent are necessary to kill molds.

However, using a blend of organic acids including, but not limited to, acetic acid, sorbic acid and benzoic acid can result in excellent mold and wild yeast control at levels well below 0.5 to 1 percent.

Conclusions

Dairy TMR is an ideal substrate and environment for mold and wild yeast growth. Because of how we process our dairy diets, we supply these organisms with a perfect environment for growth: a food source, adequate temperature, oxygen and available water.

Silage inoculants can help reduce opportunities for mold and wild yeast growth by rapidly driving pH of silage to a level where growth and multiplication stop.

Blends of organic acids and organic acid salts are effective at controlling mold and wild yeast growth. These mold-inhibitor products are incorporated into the TMR to control microbial growth when the ration is mixed. ![]()

PHOTO: Loading the feed truck. Photo by Emily Gwin.

References omitted but are available upon request. Click here to email an editor.

-

Eugene Rodberg

- Sr. Product Manager

- Kemin Industries

- Email Eugene Rodberg