The use of commodity feeds, such as corn gluten feed or soybean hulls, in dairy rations is not a new concept to the dairy industry. Commodity feeds have been used by feed companies and larger dairies for many years.

However, it is a new concept to many producers in some areas. As herds become larger, they can more economically use larger quantities of feed in a specific period of time.

Commodity feeds are byproducts from a variety of sources in the feed processing industry which may be used as an alternative feed for livestock. Most, but not all, commodities in dairy rations are byproducts from the manufacturing of other feeds and have nutrients that are available to be used by animals in the dairy industry.

Most commodities are limited in some nutrient as they are byproducts of the production of other feeds; some nutrients are extracted from the original feed in greater quantities than others during processing.

Most dairy producers use commodities in the ration to either lower total feed costs or to extend the amount of feed on the farm. Both purposes can justify the use of commodities.

For individual commodities, factors affecting their use on the farm include the nutritional composition of the commodity, the availability of the product, the relative value of the commodity in relation to other feeds, shipping costs, storage of the feed and the amount of the commodity that can be used daily, which will also relate to the amount of time the commodity will be stored. An additional factor affecting the use of commodities is the effect on milk production.

The biggest problems in feeding commodities involve storage of the product (as most commodities are delivered to the farm in tractor-trailer loads), the capital tied up to purchase equipment to use the commodities and also changing the ration when commodities might not be available.

A commodity feed must provide nutrients needed in the ration before being considered for purchase. Commodity feeds may be classified according to their use, including energy suppliers (>80 percent total digestible nutrients, TDN), protein suppliers (>20 percent crude protein, CP), fiber suppliers (>20 percent acid detergent fiber, ADF; >40 percent neutral detergent fiber, NDF), medium protein suppliers (14 to 20 percent crude protein, CP), bypass protein suppliers (>30 percent undegradable intake protein, UIP) and multiple nutrient sources.

Some feeds can be in more than one classification. The type of commodity feeds selected should be feeds that complement the remainder of the ration, usually the forage in the diet.

It is usually not economical to purchase a high-protein commodity, such as corn gluten feed, when protein is not the limiting source in the diet, e.g., the use of high levels of corn gluten feed with high-quality alfalfa hay as a primary forage in the diet usually would not be economical. Instead, the use of high-energy feeds, such as hominy or whole cottonseed, may better complement the remainder of the diet.

After determining that a commodity feed provides nutrients needed in the ration, one of the first factors to consider when selecting commodities is availability of the product.

Many products may be generally available at various times during the year. However, some products, such as rice bran or citrus products, may be more limited in their availability at specific times during the year.

Availability of the byproduct on a consistent basis is important when first purchasing the feed, as changes in the ration of the high-producing dairy cow should be minimized.

If sufficient quantity of a commodity feed is not available for several weeks, it is questionable whether changing the current feeding program is recommended.

Price or relative value of the product compared to other commodities should be considered when purchasing the product, also. Price, even more so than availability, may fluctuate throughout the year but must be compared to the nutritional value of other available feeds in order to minimize total ration cost.

Numerous computer programs are available to assist in comparing the price of commodity feeds compared to corn and soybean meal or other feeds and are available from your local Cooperative Extension Service.

However, these calculations can be misleading, as commodity feeds are generally deficient in one or more of the nutrients commonly available in corn and soybean meal. For example, many commodity feeds are very low in calcium or phosphorus or, in some cases, energy or protein.

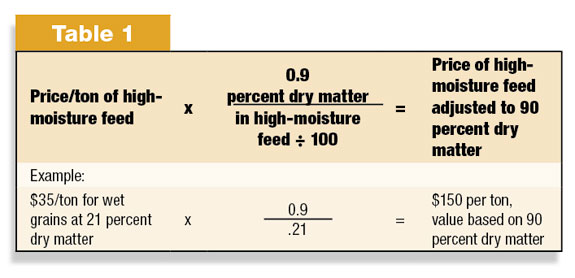

Dry matter content of the commodity has a marked effect on its value per pound. Most commodities will be 85 to 90 percent dry matter, which allows their comparison on a fairly even basis.

However, some commodities, such as wet distillers grain or wet brewers products, must be compared on a relative percent dry matter basis to other commodities, e.g., 90 or 100 percent dry matter. These commodities tend to require more cost for shipping per pound of dry matter but may be competitive in the ration if the price at the site of origin is competitive.

The formula found in Table 1 may be used to adjust wet feed to a 90 percent dry matter basis.

Shipping costs must also be considered when purchasing commodities. For example, whole cottonseed is normally a good buy in the South, as the seed is produced in that area.

However, the use of products such as citrus pulp may not be a good relative value, as it must be shipped from Florida or other areas, which may diminish the relative value of the product.

Storage facilities to hold quantities of large tonnages of one or more commodities are necessary in order to effectively use commodities.

Buying commodities in bulk may save many dollars in feed costs each year, but the additional cost of storage and handling facilities to feed commodities must be considered in making the decision to use commodities in the ration.

As a rule, the minimum requirements for storage of commodities involve a storage bin, usually with three or more bays. The storage bin should be at least 10 feet wide to allow for maneuvering trucks for unloading.

Generally, the inside height must be at least 12 feet to allow clearance of the truck bed, and additional footage is necessary if dump trailers are to be used. The sides of the bin should be solid at the bottom for at least five to six feet to prevent commodities from mixing.

In some cases, space may be available or may be adapted from livestock or tool barns that exist on the farm. It is important to design a facility that will keep the feed dry and safe from weather damage as well as minimizing exposure to rodents and other wild animals. A concrete floor is usually required in the commodity barn.

In addition to a commodity shed or barn for the storage of the feed, additional capital will be tied up in a mixer wagon to feed commodities as well as a tractor to pull the mixer wagon.

In some cases, commodities may be fed with a front-end loader, but generally that is used when only a single commodity is used on the farm.

Another factor to consider when purchasing commodities is the amount of space occupied by the commodity as well as the amount of time required to use the commodity.

As a general rule, a truckload of commodities should be fed in less than 30 days and in almost all cases, in less than 60 days.

Exceptions to this general rule may be the purchase of feeds during or shortly after harvest when prices tend to be at their lowest.

For example, some producers will purchase a yearâs supply of whole cottonseed at the time of harvest because prices are generally more favorable, even considering the loss during storage as well as the interest on the investment during the year.

An additional consideration is the amount of time or the amount of feed that can be fed each day. For example, if the maximum amount of a commodity that can be fed each day is four pounds per head per day in a 150-cow herd, only 600 pounds of the commodity will be fed each day.

If a load of feed is 42,000 pounds, it will take 70 days to use the feed. Another factor to consider is the amount of space for the feedstuff.

Most of this article has included information that deals with use of commodities to lower the overall feed costs of the dairy herd. However, in some cases, commodities are purchased in order to extend the amount of feed on the farm.

Common feedstuffs to extend fiber sources on the farm when homegrown forage is limited include cottonseed hulls, soybean hulls and citrus byproducts.

Even brewers grains and distillers grains may be used as a source of fiber when complemented with other forages. In purchasing these types of commodity feeds, nutritive value of the product may be less of a factor in the decision to purchase the product than the desire to provide a balanced ration with adequate fiber.

With commodity feeds, the producer also needs to be aware of variations that exist in nutrient content of the commodity.

Moreso than whole food products, such as corn, soybeans, wheat and cottonseed, the nutritive content of commodity feeds will vary with the location of the processor as well as the specific processing method used to yield the byproduct feed.

This is especially true of products such as dried bakery wastes and other commodities derived from the production of more than one product at the processing site.

Balancing the ration

Providing a nutritious diet to the dairy cow at an economical cost is the primary purpose of commodities in most dairy rations. It is important to consider the effect on milk production of using commodities, as generally high-producing cows are more profitable than low-producing cows.

When using commodities, rations must be balanced for various minerals as well as provide an adequate vitamin premix in the ration. Generally, the use of commodities in the dairy ration will not be economical if milk production is sacrificed.

Where to purchase commodities

Commodity feeds are available from many brokers and feed dealers. In purchasing commodities, use a reputable dealer and establish a network where you can call various dealers to purchase commodities.

Periodically, compare prices with other dealers to verify that your primary supplier is competitive.

Summary

Commodities may be used to lower total feed costs or to extend the feed on the dairy farm. The biggest problems in using commodities include storage of the feed, capital to purchase equipment to feed it and the effect on milk production of the cow when changing the ration.

Factors to consider when using commodities include:

- Nutritional composition of the commodity;

- Availability of the commodity;

- Relative nutritional value of the commodity compared to other feeds;

- The shipping cost of the commodity to your facility;

- The storage of the commodity on the farm and length of time to use a load;

- Balancing the ration to minimize effect on milk production if the ration is changed. PD

âExcerpts from University of Arkansas Cooperative Extension Service Agriculture and Natural Resources newsletter

-

Jodie Pennington

- Regional Ruminant Educator

- Lincoln University Cooperative Extension

- Email Jodie Pennington