The cool, wet spring delayed planting and led to a late harvest. Producers had to make tough decisions on the best time to ensile their forages, either before or after the (killing) frost.

As this new corn silage starts being fed out, it is vital to keep in mind the specific growing and harvesting conditions experienced. It will help producers manage expectations for the resulting feed and properly balance rations, allowing cattle to achieve the best performance possible according to their genetic potential.

Late corn planting

Delayed corn planting and irregular growing conditions caused variations within the stand maturity, final plant quality in the field and expected yields, which will be generally lower. Overall, 2019 corn silage will have less grain and, consequently, low starch (energy) content.

The initial question resulting from delayed planting was: Would there be enough growing degree days for the plant to reach desired maturity? The late planting and lower fall temperatures in some areas could have extended the usual 45 days needed from silking to silage harvest maturity to between 60 and 65 days. Additionally, due to the later start, the time of harvest was inevitably one to two months late, which likely meant harvesting immature, frost-damaged or frozen corn – especially in Canada and the northern U.S.

Weather effects during harvest

Because of the wet conditions, getting in the field and the harvest process were both more difficult. Continued rain outbreaks also compromised the window of time available for chopping and filling up the silo. This season, farm machinery often got stuck in muddy ground (Photo above), which meant additional expenses to get the equipment unstuck – but also lost time.

We can expect to see soil contamination in the silage coming from many different sources during harvest, e.g., on tires from the field, dirt pads in and around the storage area and more. As a result, we can expect to see high ash values in silages. Corn plants have internal ash levels of about 4% dry matter (DM), and each extra percentage point represents 10 kilograms (22 pounds) of soil contamination per ton of corn silage.

As well as increasing the ash level, soil also harbors undesirable micro-organisms such as clostridia, fungi and enterobacteria, which can negatively impact fermentation. For this type of scenario, a proven, effective homolactic forage inoculant should have been used to minimize activity of the unwanted microbes and to efficiently drive fermentation – saving nutrients and reducing shrink.

Although whole-plant corn with a high degree of soil contamination due to a hurricane fermented fairly well, research done at the University of Delaware has shown that iron and aluminum contents were high, and the fiber digestibility and net energy of lactation were lower compared to silage made from corn not affected by the hurricane.

Corn harvested before frost/snow

The recommended moisture level for whole-plant corn for silage ranges from 63% to 68%. Early harvests, with moisture levels higher than 70%, can lead to increased run-off (seepage) and an extensive, prolonged fermentation. This can result in a high acid load that may depress feed intake. Clostridial growth is rarely an issue in corn silage, even if wet, but the extra moisture may stimulate microbial activity in general. These silages typically have a low ratio of lactic-to-acetic acids; a higher degree of protein breakdown expressed as soluble protein and ammonia-N; along with greater levels of other fermentation products, such as alcohols and esters, some of which may have a negative impact on intake and performance.

In addition, seepage loss during ensiling results in the loss of soluble, highly digestible nutrients (sugars, organic acids, soluble-N and soluble minerals).

These immature plants will have greater sugar content and lower starch levels because the plant sugars did not have the time to be converted into starch. In addition, producers can expect higher fiber and crude protein contents. Thus, the energy value of immature corn silage will be 85% to 90% of regular corn silage. Although fiber levels will be higher than normal, it may be more digestible, depending upon the maturity when frosted, and may feed quite well.

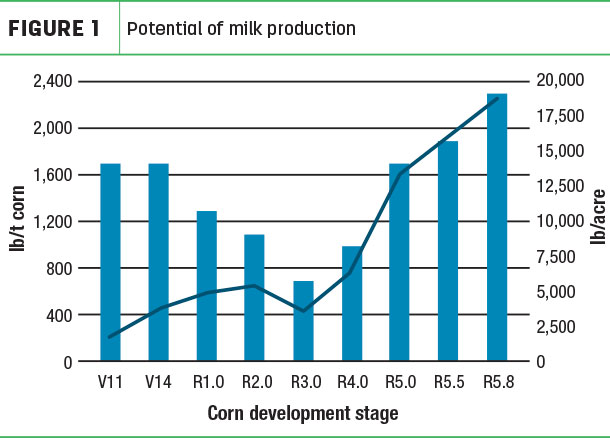

There has been some interest in harvesting extremely immature corn, possibly to dodge a coming frost. In this scenario, the corn is harvested before the reproductive growth of the plant and treated like a grass forage. Corn plants are mowed during the vegetative phase, wilted and ensiled or baled for the best quality (Figure 1).

Corn harvested after frost/snow

A quick frost should not be too detrimental; although the plants appear dry, there is still plenty of moisture in the stalks. If the portion of the plant above the ear is alive (green color compared to brown) after a frost, it will advance in maturity, and the kernels will still accumulate starch from soluble sugars.

If the plant was killed, it loses moisture rapidly. This could lead to ensiling the material too dry, making compaction more difficult. Additionally, frosted kernels and other parts of the plant are susceptible to fungal infestation and could possibly lead to production of mycotoxins. Freezing can also lower the natural population of lactic acid bacteria on the plants. This situation again calls for a proven, effective microbial inoculant to ensure a good ensiling fermentation.

If plants were ensiled too dry, check particle size and packing density. Pay extra attention to balance effective fiber in the ration properly. The lack of moisture in these silages results in a restricted fermentation, with lower levels of fermentation products and terminal pH values on the high end of the desired range. Trapped air will encourage plant respiration, molding and heating. This delays fermentation and results in significant DM and digestible nutrient (sugars and true protein) losses.

Mature corn will have a high starch content, but it will have lower digestibility due to being imbedded in a prolamin-protein matrix. The rate and extent of starch digestibility in the corn silage is influenced by hybrid type (e.g., floury versus vitreous kernel varieties), moisture content and storage time.

Nitrates may be a concern for frost-damaged grasses, including corn plants. If feeding soon after ensiling – almost like a greenchop – be careful with the nitrate risk at feeding. To ensure worker safety, be aware of the increased risk of toxic nitrogen dioxide gas during feedout – especially any orange fumes. The fermentation process reduces the nitrate level in the silage by 40% to 50%. Nitrate tests can be done quickly and at a low cost by forage testing laboratories.

Crops ensiled late in the season at low ambient temperatures may not ferment well and may not ferment at all if the corn was ensiled frozen. Check the silage pH, since a fast fermentation may happen even if silage looks green. As spring approaches and temperatures rise, the outer layers of silage will likely ferment, leading to inconsistent nutrient levels and possibly aerobic deterioration due to inconsistent fermentation.

Sampling and analyzing 2019 corn silage

Considering all the challenges during this growing and harvest season, sending representative samples to a credible forage testing laboratory for nutrient and fermentative profiles is a good investment, especially if the corn plants in the silo came from different fields.

Representative samples should be taken, and we recommend being careful to minimize microbial activity during handling and shipping. For example, it helps to freeze samples and ship express, preferably with ice blocks in the shipping package. Moreover, it could be worth the additional cost to run the samples through wet chemistry, considering that near-infrared reflectance (NIR) calibration is based on normal corn silages, unlike the “extreme” 2019 materials you may have. Also, test for nitrates and mycotoxins if conditions were appropriate for their presence.

Feeding 2019 corn silage

If you still have some 2018 corn silage that is fully fermented with high starch digestibility, keep in mind that the amount of soluble, degradable protein and ammonia-N increases with storage time. Take this into consideration when balancing the ration.

If you must feed the 2019 silage right away, starch content will be lower than usual, and its digestibility will be lower in the first three to six months. Expect a drop in production during this timeframe. Gradually adapt cows to the new silage with a step-up program in defined increments. For example, feed 25% new silage per week to help prevent acidosis and other metabolic issues. Consider using feed additives to help optimize rumen performance and especially ones that help maintain lower gut health. This is particularly important if high levels of molds and mycotoxins are present. ![]()

Renato Schmidt received his Ph.D. in animal nutrition from the University of Delaware and is employed by Lallemand Animal Nutrition, North America as a technical services – forage team member since 2008.

Bob Charley received his Ph.D. in microbiology from the University of Strathclyde in Glasgow and is employed by Lallemand Animal Nutrition, North America as the forage products manager since 2002. Email Bob Charley

References omitted but are available upon request. Click here to email an editor.