When we finish a TMR audit, some questions are pretty routine. “Which is the best facer to purchase?” though, is not among them. “Which is the best mixer?” is among them. Yet, both the facer and the mixer affect feed quality every day of the year. Do you give equal consideration to the facer and mixer you use?

Recently, a Wisconsin dairy asked me to help determine which facer was best for them. This presented a great opportunity to get a better handle on how different facer types impact the TMR. The dairy owned both a rake facer and a rotary facer.

The feeder and owner differed on which facer was best to use. The feeder wanted to use the rake as he could face the silage four to five times faster with the rake than with the rotary facer.

The ridges the rake left, however, concerned the owner, who preferred the smoother face left by the rotary facer. He felt ridges left a place for the feed to heat. Big picture, the less exposure silage has to air, the better preserved it stays.

We agreed that the feeder would face both the corn silage and haylage with both facers the day before my upcoming visit and leave a pass for each facer to make on the day of my visit. I would then read the temperature of all the passes with an infrared camera.

The rotary facer has many moving parts and bearings. The rake facer is a solid piece with no moving parts. Hydraulics move the rake facer up and down.

Face surface

See Versus 1 of the haylage faced with both facers. This is a side-by-side example of the surface the two facers leave on haylage. The rake facer was used on the right; the rotary facer, on the left.

See Versus 2 of the corn silage. This is a side-by-side example of the surface the two different facers leave on corn silage. The rake facer was used on the right; the rotary facer, on the left.

Temperatures

After both facers had been used, temperature readings were taken of all the faces using an infrared camera. With the haylage, the high temperatures from the morning were 72.7ºF for the rotary facer and 75.3ºF for the rake facer. High temperatures from facing 24 hours earlier were 74.2ºF for the rotary and 73.2ºF for the rake.

With the corn silage, the high temperatures for facing that morning were 75.3ºF for the rotary facer and 76.8ºF for the rake facer. High temperatures from facing 24 hours earlier were 73.3ºF for the rotary and 73.5ºF for the rake.

The widest spread in temperature was only 2.6 degrees and were from the haylage faced that morning. It doesn’t appear to be a major difference in face temperature with either facer (see Versus 3 ).

Penn State shaker box

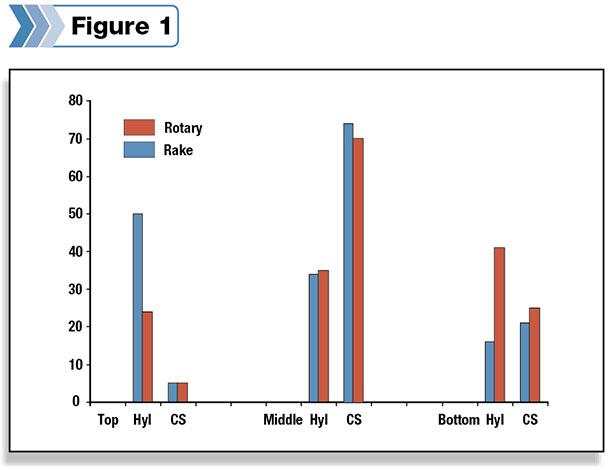

In the second part of the experiment, the difference in particle length between the rotary and rake facers was determined using a Penn State shaker box (see Figure 1 ).

The rotary facer changed the particle size of alfalfa haylage quite a bit but did not significantly change the particle size of the corn silage. The rotary in this example took 25 percent of the haylage from the top screen and put it on the bottom pan without changing the middle much. That’s a huge change in particle length by the rotary facer.

Impact on diet and cows

How does this impact diets and cow performance? First, let’s recognize other considerations such as haylage clumps, which are sometimes found along the bunk. The rotary facer helps eliminate these.

I would predict that the rake facer leaves more haylage clumps, especially during winter freezes. This could affect mix order. However, if your TMR struggles to get enough effective fiber on the middle and top screens of the Penn State box, then a rotary facer certainly won’t help.

Also consider the maintenance and wear and tear on the facer itself. I have never seen a rake broken down on a farm. This does not mean rakes do not break, but they are less likely to have problems.

The rotary facers, on the other hand, take a lot of abuse and are the most broken-down piece of equipment I see on farms. When figuring out which facer to use, be sure to consider all these factors before finalizing your decision. PD

Mitchell Deimund is a sales manager with Diamond V.

PHOTOS

TOP: Haylage faced with a rotary facer, top, and rake facer, right.

MIDDLE: Corn silage faced with a rotary facer, left, and rake facer, right.

BOTTOM : Infrared image of haylage faced that morning. Photos courtesy of Diamond V.