The ideal dairy stall is clean, dry and comfortable. Yet when it comes to keeping moisture and pathogens at bay, many stalls fall short. Whether you’re bedding on organic or inorganic material, optimizing stalls for maximum cow health and comfort is critical for producing quality milk.

Take a look at the following design elements and bedding characteristics in your own barns. Chances are you’ll see several opportunities for reducing moisture, minimizing bacterial load and improving cow comfort for higher milk quality.

Surface moisture

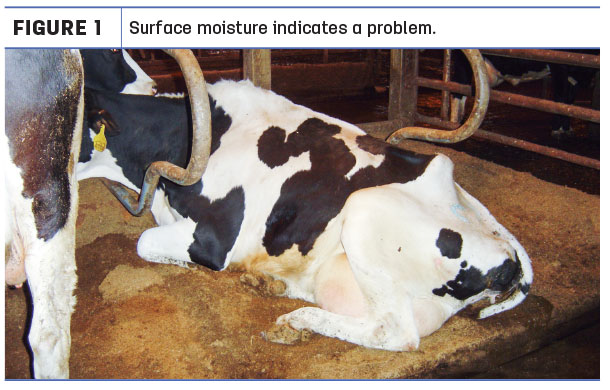

Scan the bedding surface. Is moisture evident? Moisture, heat and food (organic matter) are the three life-sustaining requirements of bacteria; take any one away, and you’ll greatly reduce the ability of bacteria to survive. Optimum moisture content for bedding is 10 percent or less for sand and 70 percent or less for dried manure solids.

Dry, well-maintained bedding at the proper depth allows liquids to drain or evaporate. Obvious moisture on the bedding surface indicates a problem with the bedding materials, bedding depth or an overall lack of maintenance (Figure 1).

Interior moisture

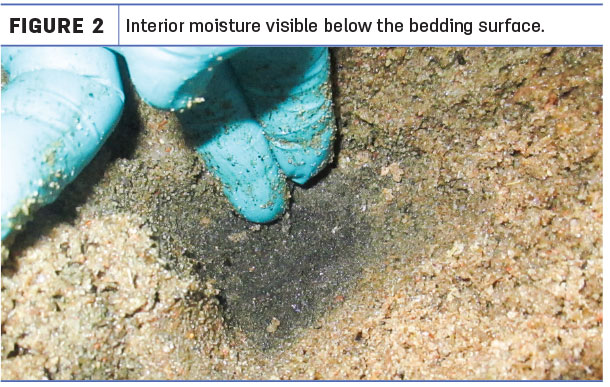

What about moisture you can’t see? Scrape below the surface of the bedding. A wet, black line indicates a problematic combination of moisture and organic matter. Note how the sand sticks to the veterinarian’s glove; this is a sign of high moisture content and high bacterial growth potential. Stalls with this level of contamination should be completely dug out and replaced with clean, dry bedding (Figure 2).

Bedding depth

A hoofprint of a half-inch or less in well-packed sand indicates the bedding is not deep enough to provide a comfortable base. Dairies using reclaimed sand should strive for a bedding depth of 4 to 6 inches. Any deeper, and the sand tends to hold moisture and grow bacteria.

For cows bedding on dried manure solids, aim for a depth of 2 inches. Solids that are thinly spread will dry out faster, but don’t let them dry to the point of becoming airborne.

Side rail design

Side rails should be at least 18 inches high with a wide-open front to reduce the risk of injury to the cow’s bony structures. Rails that swing upward make it much easier for the cow to get up and lie down, and increase the likelihood the cow will back up and deposit manure or urine into the alleyway instead of the stall (Figure 3).

Brisket boards

Properly installed brisket boards will be visible about 3 to 5 inches above the surface of the stall. The combination of neck rail height and correct positioning of the brisket board can result in excellent stall usage with less manure and urine contamination. Improperly installed brisket boards can be a big negative to stall usage in some facilities.

Neck rails should be set to a height of 48 inches above normal sand or bedding surfaces and back from the midpoint of the brisket board by 4 to 6 inches.

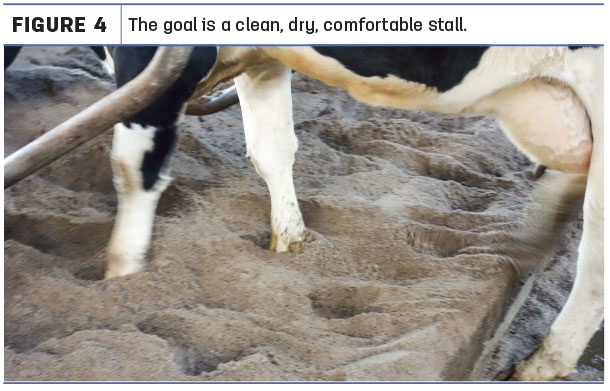

The goal: A clean, dry, comfortable stall

In a well-designed, well-maintained stall, the cow’s feet basically disappear when it walks into the stall. Sand is bedded at a depth that drains away moisture and conforms nicely to the cow when the cow lies down, yet is not so deep moisture and pathogens are retained. The sand is dry, acting as an abrasive to clean between the toes and providing good traction. The cow can lunge, get up and lie down with ease.

This soft sand is only going to be observed in stalls being deep-groomed on at least a daily basis or, better yet, at every milking. The result is a healthier, more comfortable, productive cow and overall improved milk quality (Figure 4).

Several management practices can further minimize moisture and pathogens in recycled bedding:

- Get bedding as dry as possible through mechanical conditioning over several days or by using equipment specifically designed to dry recycled sand or dried manure solids. Roll presses, screw presses, dewatering screens and bedding dryers are valuable tools for quickly removing liquids and pathogens.

Bedding dryers dry very quickly. Newer models can be configured to process 5 to 30 tons of sand or more per hour. For dairies bedding on solids, a dryer can process between 1 and 10 tons of manure or more per hour, greatly reducing labor and time requirements for traditional moisture removal.

- If using dried manure solids, let the material sit for a couple of days before using it for bedding. Wait another week before adding fresh solids. Studies have shown bacteria in organic bedding reach their highest concentrations within a day or two of being placed in stalls.

- Remove fresh manure deposits promptly inside and outside the stall. Be aware, cows sometimes back in and deposit manure at the rear of the stall.

- Keep stalls ventilated and well drained.

- Avoid overcrowding of animals.

- Take extra care with maternity pens and stalls for at-risk cows, such as dry cows and close-up heifers.

- Protect stored bedding from rain and snow.

Bedding is a major growth reservoir for mastitis-causing pathogens. With the right stall design and careful ongoing management, dairy producers can significantly improve cow comfort, reduce health problems and enhance milk quality. ![]()

David Reid, DVM, is owner of Rocky Ridge Dairy Consulting.

Renee Schrift is the director of sales – agricultural products with McLanahan Corporation. Email Renee Schrift.