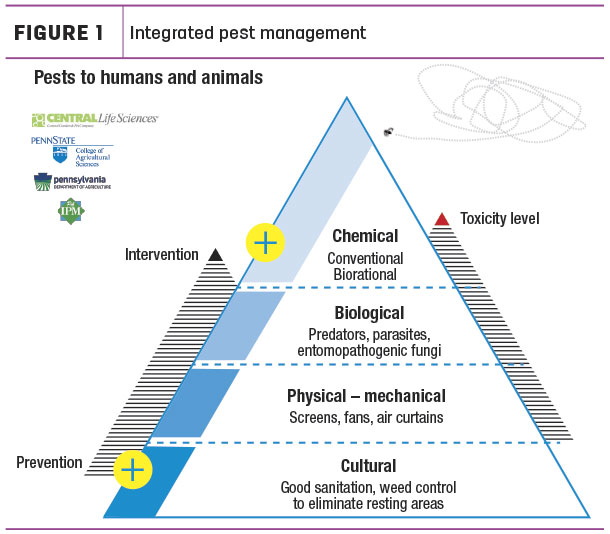

Integrated pest management (IPM) is a pest control strategy that uses an array of complementary methods to reduce pest populations (Figure 1).

IPM plans incorporate various routine practices and control methods in an effort to keep fly populations in check and below an established economic threshold – the number of flies per animal in which the economic losses resulting from the pests outweigh the costs to control them.

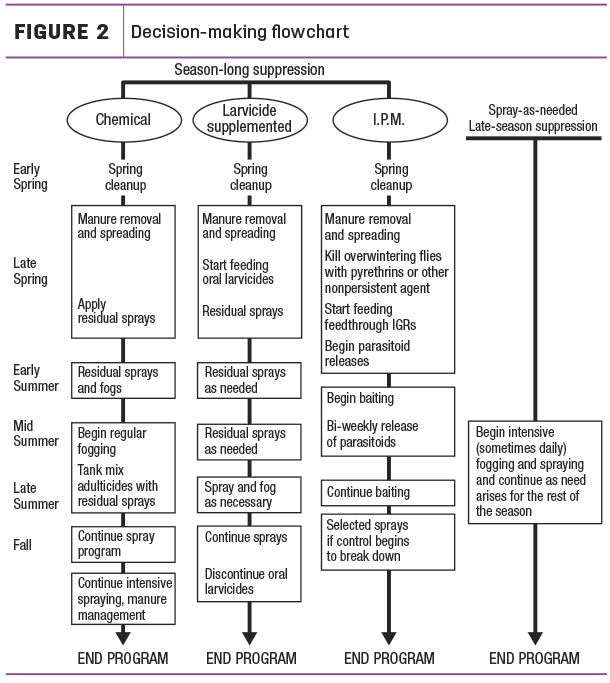

There are four crucial components to an IPM program: cultural, physical/mechanical, biological and chemical (Figure 2).

The cultural and physical/mechanical steps form the foundation of any comprehensive fly control program. It is important every effort be made to keep an operation in optimal condition and limit the number of potential breeding and shelter sites sought by nuisance flies.

Cultural

Cultural efforts include sanitary practices around a facility, with tasks such as manure management, landscape maintenance and routine cleaning of spilled feed and milk, and other vegetative buildup from cattle areas. Manage manure in a timely and consistent manner, as manure is the primary breeding site for flies. Clean spilled milk or milk replacer and decaying straw and wood shavings in calf bedding, which can also serve as a breeding site for flies.

Other elements of cultural control efforts involve regularly cleaning and moving calf hutches and pens to keep them well ventilated. Flies rest in tall grasses and weeds, so removing those will help remove fly presence. On pasture, clear or spread out grass clumps or mulch when possible.

Physical/mechanical

Mechanical and physical efforts in fly control include the maintenance of all structures and facilities that deny flies access and make the areas less hospitable to the pests. These efforts are aided by the strategic placement of non-insecticidal sticky, bag and jug traps around the premises. Many of these products are odor-free, providing ideal fits for enclosed spaces. Install fans to produce a downward and outward air flow that can limit fly activity in barns and other enclosed spaces.

Additional tasks include caulking, filling holes and sealing around electrical outlets to negate entry points and keeping the garbage tightly sealed and housed in an enclosed area. Patch or seal any cracks or crevices in structures and secure fine-mesh screens over any windows.

Biological

Biological control incorporates naturally occurring fly enemies to help keep pests under control. Predatory beetles and mites, parasitic wasps and fly pathogens can all be used as part of an IPM program to maximize fly control efforts with no adverse effect on animals or humans. Parasitic wasps lay eggs inside of fly pupae, interrupting the fly life cycle as they feed from within. Predatory beetles are known to locate dung and feed on the fly larvae found there.

Chemical

Once the first three components of an IPM program have successfully been implemented, operators can begin the chemical phase. This phase includes two methods of fly control: conventional and biorational.

The conventional method of chemical fly control utilizes baits, perimeter sprays, foggers and on-animal treatments to help control adult flies. Incorporating a balanced mix of fly control modes of action throughout the operation ensures a rotation of active ingredients, preventing resistance. This is particularly important with baits.

The biorational portion of chemical fly control includes the use of feed-through insect growth regulators (IGRs) that prevent the emergence of adult flies. Feed-through fly control products work by delivering a key active ingredient directly to cattle, which is then passed through into the animal’s manure where flies lay their eggs. The active ingredient interferes with the life cycle of the fly, preventing breeding, biting adults from emerging from the manure.

To achieve best results with a feed-through product, follow the 30-30 approach. Begin feeding a product 30 days before flies begin to appear and continue feeding throughout the summer and into the fall. Use the feed-through until 30 days after the first recorded frost to prevent overwintering pupae. The product should be fed to animals of all ages on an operation, treating as much manure as possible. Starting a feed-through product during the fly season will require the use of other fly control measures to reduce existing adult fly populations.

After an IPM plan is established and all efforts have been put into action, it is essential to continually monitor and measure results to evaluate effectiveness of the program. Fly populations should be monitored throughout the operation with the use of speck cards and a variety of traps. It’s important to document your progress with a concise record of locations, conditions and actions taken. Once operators have determined what steps have proven successful and where they have areas for improvement, the IPM program can be adjusted to maximize fly control efforts.

With overwhelming evidence flies can cause serious economic damage on dairy operations, the effects are very real to producers, and the importance of controlling fly populations with a comprehensive IPM program has never been more critical. ![]()

-

Casey White

- Director of Product Development

- Central Life Sciences

- Email Casey White