Finding abnormal milk when stripping a cow is like a person experiencing a sore throat: It could mean something more serious, like an infection that requires antibiotics, or it could be something that will resolve on its own.

The best course of action is to head to the doctor, get a throat swab and figure out exactly what’s going on. The same goes for on-farm culturing. It gives us a better understanding of the mastitis-causing pathogens cows are facing, and we can use that information to make the best treatment decisions possible.

For mild to moderate mastitis cases, culturing helps us identify the right animals to treat, as not all cases require or respond to antibiotics. If I were to culture 100 cows with mastitis, the results would usually follow the 30-30-30 rule:

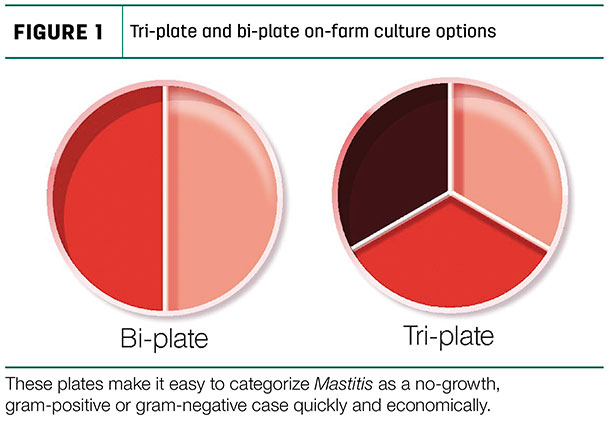

- 30% no-growth: A no-growth case means the cow has cleared the infection on her own and does not need antibiotic treatment.

- 30% gram-negative: Most gram-negative mastitis cases, including those caused by E. coli, will self-cure, and antibiotic treatment will not alter the outcome.

- 30% gram-positive: Gram-positive mastitis cases do require antibiotic treatment and can become chronic if left untreated.

If we adopt a culture-based system and stop treating gram-negative and no-growth mastitis, we can reduce the number of cases that require antibiotic treatment by 60%, which also pairs well with our industry’s efforts to use antibiotics judiciously. When dealing with a gram-positive infection, short-duration mastitis therapy can eliminate the infection and reduce the length of time cows spend in the hospital pen.

When talking with producers about whether they should implement an on-farm culturing system, I often hear two pieces of skepticism:

1. The upfront labor and costs of culturing aren’t worth it.

The upfront costs of a new system can be intimidating, but when we’re able to stop treating 60% of mastitis cases that don’t need antibiotics, the overall cost savings typically greatly outweigh those concerns.

2. I’m worried about the results being read incorrectly.

I think some producers believe they have to get down to the genus and species of the mastitis-causing pathogen, but a culturing system doesn’t need to be that complex. In fact, keeping it simple is the best piece of advice I can offer producers. A case report presented at the National Mastitis Council showed that when farms kept their culturing programs straightforward and only identified gram-positive, gram-negative or no-growth cases, it improved the overall accuracy of their results when compared to an outside reference laboratory.

To get started with a program, get in touch with your veterinarian and see if on-farm culturing is right for your operation. Once you’re ready:

-

Gather the needed supplies. You’ll need clean test tubes to collect aseptic milk samples, sterile swabs to plate milk onto culture plates, culture plates and an incubator that remains at a constant temperature to grow bacteria. A thermometer to monitor incubator temperature is also essential.

-

Identify a designated space. It really just requires a small area of counterspace for the incubator and a refrigerator, in which to keep your new culture plates stored. The area should be clean and free of drafts that could cause contamination when plating samples.

-

Determine your culturing protocol. I recommend working closely with a veterinarian and utilizing the Minnesota Easy Culture System User’s Guide. It provides step-by-step instructions for starting up a culturing system, including how to take proper samples, read culture results and maintain lab quality.

-

Train and retrain. Personnel will have to understand how to properly harvest milk samples, plate those samples, and read and record results accurately. Provide training protocols in the language that’s easiest for your employees to understand, and offer a refresher training twice per year to prevent protocol drift. Remember, your employees want to understand the “why” behind the process, and training leads to improved employee engagement and retention.

-

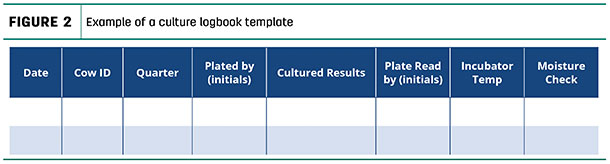

Keep good records. Records can be kept in a logbook (Figure 2) by your culture lab or recorded in your current computer software program.

At a minimum, record the sample date, cow ID, affected quarter and the final culture result. Ideally, one person would be in charge of keeping records. Down the road, these records can help you make thoughtful decisions about which animals should be treated or culled.

- Verify your culturing results with a veterinarian or diagnostics lab every few months to ensure program accuracy. Freeze your samples after plating and send 10 to 20 samples to a reference lab once per quarter to cross check against your on-farm results. Low agreement may indicate it’s time for a refresher training.

Not every case of mastitis, or case of a sore throat, needs to be treated. Culturing gives us an opportunity to make thoughtful antibiotic decisions that are better for our cows, better for our farms’ bottom line and better for our industry.

References omitted but are available upon request. Click here to email an editor.