The ability to make more informed management decisions is one of the most useful outcomes of cow monitoring and robotic milking systems Thanks to this technology, you and your team can discover nearly any cow, group or herd health performance detail imaginable with a few clicks of a mouse.

But with the virtual mountain of information comes the concern of data overload. Break free from number clutter and keep herd management on track by following these three recommendations:

1. Track cow and equipment metrics daily, monthly and annually

Break your data focus into two areas: cows and equipment. The information generated by your systems allows you to manage by exception. Seek data that differs from cow to cow and from yesterday’s performance. Then break the data into daily, monthly and annual bites.

From a cow standpoint, monitor daily reports for cows that show signs of estrus. Also be on the lookout for changes in rumination level, which may be an indication of a change in health status. Cows on these daily reports need your attention today. Earlier detection may result in reduced treatment costs and a higher intervention success rate.

Track peak production for your cows and when it occurs, especially for first-lactation animals. Do this on a monthly basis as well as annual. This information indicates how well cows handle the transition period. Outliers here help provide insight into heifer-rearing and dry cow programs, as well as possible starting points for nutritional evaluations.

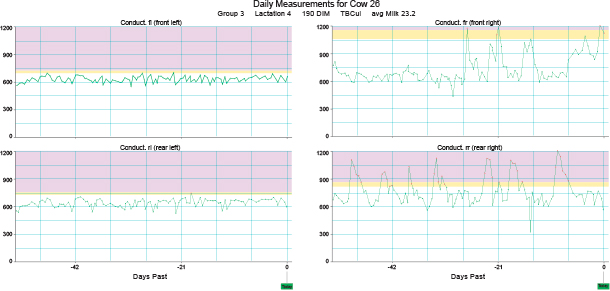

If you have a robot, review daily reports for udder health. Monitor individual quarter performance data for lower milk production, higher conductivity or higher somatic cell, depending on what sensors and information you have available to you. These data points enable you to more proactively help cows fight off infections.

Keep an eye on robot equipment each day, too. Equipment reports, including stall performance and incomplete milkings per stall, can help technicians dig into units that may be underperforming. The data can help guide the technician’s next steps and indicate the issue at hand.

Also take a step back and examine longer-term robot equipment trends. How well are cows trained to use robots? How long does it take for a cow to reach three-plus visits per day? Monitor these areas monthly to help assess training protocols and whether goals are being met.

Longer-term cow and equipment monitoring can also help you make more effective culling decisions. Data can help identify cows that don’t adapt to the system or have trouble with the stall itself. Track monthly and assess overall cow-robot interaction performance semi-annually.

Look at visit distributions over time to know when robots are busy or when the system is busy. Monitor monthly and yearly. That data can help dictate the feed pusher or manure-scraping schedule to help get cows interested in eating and then coming to the robot. The information may also spur a lighting change or another management action.

2. Set and monitor benchmarks using these data

Determine your farm’s goals based on feed, labor, other farm inputs and operational specifics. Once you’ve got your goals mapped out, set key performance indicators (KPIs) that demonstrate you are meeting your goals. Example KPIs include: milk production, milk quality, robot performance, health incidence, reproductive performance and cost of production.

It’s important to set a benchmark for your chosen KPIs and then monitor against actual farm performance. Watch trends to evaluate performance and ensure your dairy is headed in the right direction based on your goals.

When benchmarking, don’t overlook monitoring where time is spent on the farm so you can make the best use of labor while recognizing cost-saving opportunities. Even automation like alley scrapers can save a lot of time and ensure employee efforts are as efficient as possible.

Also keep in mind: When setting or adjusting your farm’s benchmarks, it’s often helpful to work with your dealer to look at a comparable farm’s goals and benchmarks.

For example, “My herd benchmark is X, and a similar farm is at Z. Do I want to make changes?” Some changes will be warranted, while others may not make sense from an economic or productivity standpoint – use the data from your reports for this analysis.

The key is to take a hard look at each of the KPIs, know what goes into each benchmark and understand what the results mean for your farm and management so you are making accurate and actionable comparisons.

3. Marry up cow and equipment data for early intervention

A daily equipment report may indicate a cow didn’t get milked out properly in the robot. But sometimes what may appear as an equipment issue can be a cow issue – and it takes marrying up the equipment and cow reports to get to the bottom of things. In this case, the cow’s record may show she’s simply decreasing in production or has a health challenge (no equipment error).

Use daily equipment monitoring and cow health reports together to quickly identify potential challenges and intervene early. Looking at both reports can help get to the bottom of things and determine if you’re facing a cow or equipment issue. Then you can take the appropriate action to fix the issue at hand.

Last, trust the data. Know that you will have “ah-ha” moments, which you can learn from.

Spend time looking at the right cow and equipment data regularly so you can set, hit and even over-deliver on your farm goals.

Prepare now for tomorrow’s technology needs

If you’re considering cow monitoring or robotic milking systems, hone your herd record-keeping skills now. Adding these technologies to your herd will increase computer time significantly, even if you spend a good bit of time in front of the screen now.

Get comfortable in front of your computer. Review your records frequently and begin standardizing your protocols, if you haven’t done so already, to smooth the transition. Know that more of your time will be spent looking at numbers and analyzing data instead of spending 20 to 30 minutes walking the cows every day.