Ask any dairy farmer what type of issues they face in today’s industry, and the conversation undoubtedly will move toward money. With most farmers facing decreasing profit margins and some barely hanging on due to increased cost and a stagnant revenue stream, good farmers are always on the lookout for ways to better manage their bottom line.

One of the directions today’s farmers are looking toward in order to keep costs low and to find new revenue streams is in the field of advanced technologies.

Not only do dairy farmers look to technology to help move into complementary fields of business (such as ice cream production or cheese-making), farmers look to technology to help keep their cattle healthy and in optimal physical condition so disorders such as ketosis are prevented.

What is ketosis?

Ketosis is a very common issue for dairy farmers. It occurs when energy expenditures are much higher than the energy intake of feed. Since cattle are not getting enough energy from their feed, the body actually attacks and breaks down the fat stores in order to cover the energy gap.

The liver takes the stored fat, converts it to energy to fuel the body and when overwhelmed with this task will produce ketones, which is an acid. As this acid builds up within the body, it becomes poisonous to the cow and can cause illnesses.

This is the very same process that occurs in humans who stay on a very low-carb diet for a long period of time. Since the body’s primary energy source is glucose, which is created by eating carbohydrates, the glucose levels within the blood start to drop.

In response, the body – needing an energy source for fuel – turns to the stored fat. Although this may sound great (especially if you’re trying to lose weight), the reality is that when the body uses stored-fat fuel it can cause liver problems, ketosis buildup, and in extreme cases, coma or death.

In cattle, this disorder is often seen with the cows that are still lactating, as their energy usage greatly increases in order to keep up with milk production.

In fact, it is seen most often in cattle that have just given birth, as the body is already weak from the experience, food intake is lower during the late stages of pregnancy, and milk production is ramping up. The food intake simply does not match the amount of energy the body needs in order to be physically healthy.

Diagnosing ketosis

Ketosis is relatively easy to diagnose. As the ketones build up in the body, cattle start to show signs of illness, including weight loss, decreased milk production, reproductive issues, displaced abomasum (stomach) or even metritis (inflammation of the uterus). Other signs include fever, dull coat, excessive salivation or even an acetone smell on the breath. Lab results can confirm the farmer’s suspicion.

However, ketosis symptoms don’t start at the point when the body turns to fat stores for fuel. When the body turns to these stores, and the liver becomes overwhelmed, the ketones usually build up quite slowly. When the ketones are just starting to build up but have not yet resulted in symptoms, the stage of the disorder is called subclinical ketosis.

When ketosis is diagnosed in cattle, it can be extremely costly to treat. Not only does the farmer have to treat the symptoms, such as reproductive issues or metritis, he may also have to forgo revenue from the decreased milk production or the issues with reproduction.

However, when caught at the subclinical level, there are no symptoms to treat. Therefore, the aim of every farmer is to detect ketosis during the subclinical stage while it is still relatively easy and inexpensive to treat.

Laboratory tests can definitively confirm whether ketosis or subclinical ketosis exists. After diagnosis, the cattle may be treated with propylene glycol, dextrose and Vitamin B-12. These help to increase glucose levels and provide enough energy input in order to keep up with energy output.

The cost of ketosis

It’s difficult to determine an accurate cost of ketosis. Prices for milk and beef fluctuate wildly at times, and it’s difficult to get an accurate count of how many cattle are affected.

However, as a result of multiple surveys completed in the previous years on cattle herds in the U.S., Canada, the UK and Australia, there are some commonly accepted industry standards related to the cost of this disorder.

It is estimated that between 40 percent and 60 percent of newly calved cattle actually meet the levels of subclinical ketosis. Due to the cost of testing and treating not just the disorder but also the side effects, the cost per every hundred head of cattle is estimated to be $13,000 per year. For farmers who are watching every line-item in the budget, this is an extremely high cost, one they probably cannot afford.

Detecting subclinical ketosis

The most common way to detect subclinical ketosis is through the use of a laboratory test. Blood samples from cattle are tested for their levels of beta-hydroxybutyrate. Also known as BHBA, this compound is found in the blood of both humans and cattle. When the ketone levels begin to rise, the BHBA levels rise as well.

Subclinical ketosis is indicated when the BHBA concentration rise above 1.2 mMol per L. Anything above 1.4 usually is considered full-blown ketosis and is the minimum level at which symptoms usually start. For those not in the know, mMol per L stands for millimoles per liter, which is a standard measurement of detecting blood glucose levels.

The conventional method of testing BHBA includes extracting a decent-sized sample of blood from the cow, sending off to a specialized laboratory and waiting for the results. These specialized laboratories contain expensive equipment, require complex procedures and need lab techs properly trained in the process. For all of these reasons, conventional tests are considered to be labor-intensive and time-consuming.

New technologies

Over the past 10 years or so, some fascinating advances in technologies have been introduced to the world. When it comes to detecting subclinical ketosis, cowside tests are now the goal of every newly invented product. Being able to more quickly detect this disorder without going through the conventional process using an outside laboratory would be a huge boon for farmers.

However, not all of these cowside tests have been successful. Although some do show success, there are others that are simply not effective or accurate or have too high a price tag.

One of the issues many of the early cowside tests faced is that the equipment was created for human glucose detection and later converted for use with cattle. Unfortunately, these are the cowside tests that have proven to be less accurate than others.

What this all means to today’s farmers is that on-site, cowside testing may not be considered a definitive test. Some farmers using this technology will also send the samples to a laboratory in order to verify results. This adds time and money to an already timely and costly process.

The future of cowside testing

The future of cowside testing comes in the form of advances made in the arenas of microfluidic technologies, biosensors, quantum dots and lab-on-a-chip technologies. Although not technical descriptions, the information below generally describes what each of these technologies do.

- Microfluidic technologies are those technologies designed to operate on an extremely small fluid sample. Microfluidic technologies can handle drops of liquids as small as one billionth of a meter. This means today’s farmer no longer needs vials of blood in order to get an accurate result.

- Biosensors are designed to detect biological material in very small quantities. In the case of cowside testing, these are created to work specifically on cattle fluids as opposed to human fluids.

- Quantum dot technology uses optical sensors and color filters in order to better measure the BHBA levels and is found to be hypersensitive and extremely accurate. Outside of the cattle industry, this technology has found a place in the development of the next generation of phones, tablets and televisions and is used to enhance color and clarity.

- Lab-on-a-chip technologies basically use advances in chip technology to recreate the functioning of a large laboratory and import it into a very small device. For the purposes of a cowside test, this means some type of hand-held or portable device.

New research developments

It’s exciting to see all four of these technological advances come together to help further advance farming processes. Product development is moving toward using these types of technologies in order to develop cowside testing that is portable, extremely sensitive to very small fluid samples, guarantees accurate results and provides results much quicker than an outside laboratory.

Nano Biosensor is a newly invented prototype of a cowside ketosis-testing mechanism. It was developed by researchers in the BioNano Laboratory of the University of Guelph.

Designed specifically to test for subclinical ketosis in cattle, it is a hand-held portable device, using an extremely small sample size with the results being available in approximately one minute.

Due to the use of advanced technologies, it is highly sensitive to BHBA and during testing was on par with conventional laboratory procedures when it came to reliability and accuracy.

Since this prototype can detect very small amounts of BHBA very quickly, it is recommended for use on recently calved cows that, although appearing healthy, might be suffering from subclinical ketosis. When detected early, the farmer can simply supplement the feed in order to provide higher levels of glucose and avoid the major illnesses, side effects and costs associated with full-blown ketosis.

We expect the sensor will be commercially available within a couple of years, provided the licensing process is smooth with the potential manufacturers.PD

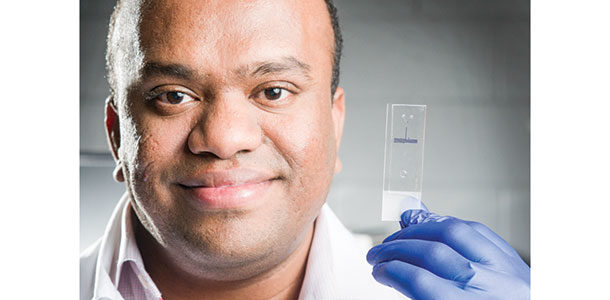

PHOTO

Dr. Suresh Neethirajan displays the sensor device to test for subclinical ketosis. Photo courtesy of Suresh Neethirajan.

Suresh Neethirajan

Assistant Professor

Director of BioNano Laboratory

School of Engineering -University of Guelph