The most exciting new dairy technologies as selected by dairy farmers were on display at this year’s PDPW Business Conference in Wisconsin Dells, Wisconsin, March 17-18.

Progressive Dairy hosted these technologies along with PDPW on the brand-new Nexus Innovation stage – a live-format presentation that was a cross between a TED Talk and a Shark Tank pitch.

“We’re excited to partner with Progressive Dairy on this exciting new platform for discovering innovation for dairy farmers,” says PDPW Executive Director Shelly Mayer. “Innovation can come from many different places – both within the industry and without. We are most pleased with the participation in this year’s competition and look forward to another round of awards at next year’s conference March 16-17, 2022.”

Here’s the five companies recently awarded with a Nexus Innovation Award from among more than a dozen applicants.

Augmented reality headset for use during herd check

An example of what a user would see when looking through Nedap’s augmented reality device that displays dairy cow data in a new way. “Augmented reality is one of those technologies that has the potential to revolutionize the way we interact with technology by making data easier to access and more natural to interact with in the real world,” says Nedap Livestock Management Innovation Manager Roxie Muller. Photo courtesy of Nedap.

An example of what a user would see when looking through Nedap’s augmented reality device that displays dairy cow data in a new way. “Augmented reality is one of those technologies that has the potential to revolutionize the way we interact with technology by making data easier to access and more natural to interact with in the real world,” says Nedap Livestock Management Innovation Manager Roxie Muller. Photo courtesy of Nedap.

Nedap has developed a system that combines the use of an augmented reality device with the insights generated from collar-worn smart tags and cow locating to monitor cows’ behavior and performance.

“Augmented reality is a way we can view holograms in the real world,” says Roxie Muller, innovation manager at Nedap Livestock Management. “Holograms or augmented reality is something we’ve seen in many sci-fi movies. The technology is finally mature enough to be used. Augmented reality is one of those technologies that has the potential to revolutionize the way we interact with technology by making data easier to access and more natural to interact with in the real world.”

If using the company’s existing cow-locating technology and activity monitoring collars, customers could see a cow’s data displayed immediately over the back of a cow through an augmented reality headset. All relevant insights of a cow’s health, fertility and nutritional status as well as the location of the individual animal are displayed as floating holograms through the headset. These holograms give the herd manager wearing the augmented reality headset insights about which animals need attention in a single glance.

If close to an animal, the user can open up the hologram they see through their headset using voice commands or gestures to reveal more detailed cow information. Not only can herd managers visualize existing info about their cows, but they could also enter data into the system by pressing virtual buttons or by giving voice commands. This new hands-free approach thus eliminates data entry after a herd check back in the office.

“Dairy technology needs to be more adaptive, and it needs to conform to the user,” Muller says. “So we are striving for technology that’s in a way more humanlike and is able to adapt to us, instead of us learning how to deal with the technology.”

Muller admitted that the cost and durability of headsets may not be ready for the majority of farmers – just yet.

“Right now, the devices, even though they’re really impressive in terms of what they can do with their capabilities, we do not quite deem them farm-worthy yet,” Muller says. “We do get a lot of interest in this product from people [who] are innovators and early adopters willing to live with some of those cost and durability compromises in the beginning.”

Automated vertical farming for fodder production

HydroGreen’s vertical farming, fodder sprouting system claims it is about 1,000 times more productive at annually providing pounds of dry matter feed when compared with traditional farming of corn silage. Some early adopters of the technology have reduced the inclusion rate of corn silage in their cow diets, allowing them to expand milking cow numbers by as much as 40% without expanding their land base. Photo courtesy of HydroGreen.

HydroGreen’s vertical farming, fodder sprouting system claims it is about 1,000 times more productive at annually providing pounds of dry matter feed when compared with traditional farming of corn silage. Some early adopters of the technology have reduced the inclusion rate of corn silage in their cow diets, allowing them to expand milking cow numbers by as much as 40% without expanding their land base. Photo courtesy of HydroGreen.

HydroGreen has created a unique automated technology to grow on-site, commercial-scale quantities of fresh livestock feed, anywhere on earth, 365 days a year.

“Land is an issue of growing concern,” says HydroGreen’s Director of Business Development Brandon Peterson. “We’re losing 175 acres an hour to urban development in the U.S. How we are going to grow enough feed for our livestock is a growing concern for producers in some parts of the country.”

Through this technology, dairies can gain more control over feed production. Their own on-farm HydroGreen system helps conserve water and land without the need for chemicals or fertilizer, according to the company.

One of the system’s modules measures almost 20 feet tall and 70 feet long. An early adopter of the system – a 6,000-cow dairy – is installing multiple modules and will soon be able to grow approximately 68,000 pounds of feed on an as-fed basis, or about 15,640 pounds on a dry matter basis, every day. This installation requires just one employee working a six-hour day. The computer-controlled system grows a high-energy forage in six days that is low in starch, high in energy, high in protein, high in sugar and relatively low in potassium.

The fodder-growing system also automates feeding. It mechanically shreds the harvested sheets of fodder and root mass into individual blades and delivers them via a conveyor belt to a producer’s TMR mixer, commodity bin or batch box.

“We see good shelf life of the fodder for up to 12 hours, and even longer once combined with other ingredients,” Peterson says. “The neat thing about the germination and growing process is it creates high levels of natural hydrolytic enzymes. We have studies showing how those enzymes when combined with the other ingredients in the TMR, increase the digestibility of the entire diet.”

The company claims its fodder production uses at least 60 percent less water than traditionally irrigated farming production of forages. Peterson says the system’s annual output can far outperform traditional forage production.

For example, Peterson says traditional corn silage production at 26 tons to an acre and 34% dry matter yields about four-tenths of a pound of dry matter per square foot per year. Using the HydroGreen system, Peterson says a producer can produce about 426 pounds of dry matter per square foot per year.

“That productivity difference is about 1,000 times more productive on a dry matter basis,” Peterson says. “When you look at overall nutrition production on a per-square-foot basis, it gets really exciting in a hurry.”

Most of the early adopters are including fodder at up to 15% of diet dry matter.

“One of our limiting factors is moisture because traditionally we’re using a lot of other wet ingredients in dairy diets,” Peterson says.

Some early adopters of the technology have been able to reduce the inclusion rate of corn silage in their cow diets, allowing them to expand their milking cow numbers by as much as 40% without expanding their land base.

“The system produces a high-sugar feed. It’s about 25 to 30 percent sugar. It’s also a relatively low-potassium feed (.46% potassium),” Peterson says. “It really looks great in close-up cow and transition cow diets. It’s going to encourage intakes and really help keep those cows healthy and eating.”

Additionally, the company claims its technology helps insulate producers from drought and other weather events, allowing them to remove some production risk from their operations. Peterson says this feature has made the product of particular interest to dairies in arid regions in the West, including Texas, Utah and Idaho.

“When the feed is harvested at the end of six days, you’re going to have a feed that’s highly digestible,” Peterson says. “We provide the solution to produce consistent, fresh, on-farm, reliable, sustainable nutrition every single day on your own operation.”

Automated high-moisture corn feeder for milking robot boxes

AMS Galaxy USA has engineered an automated auger feeding system to allow dairies with milking robots to feed high-moisture corn instead of pellets in their box stalls. Photo courtesy of AMS Galaxy.

AMS Galaxy USA has engineered an automated auger feeding system to allow dairies with milking robots to feed high-moisture corn instead of pellets in their box stalls. Photo courtesy of AMS Galaxy.

AMS Galaxy USA has engineered an automated auger feeding system to allow dairies with milking robots to feed high-moisture corn instead of pellets in their box stalls.

Brad Biehl, a Pennsylvania dairy farmer and owner of AMS Galaxy, is the innovator who created the system. His farm converted to robotic milking a decade ago and, like most other dairies milking with robots, began feeding a partial mixed ration at the feedbunk, with the balance of the diet fed as pelleted concentrate inside the robot. However, pelleted feed can be expensive. Knowing what he knows now, Biehl calls pellet feeding “the hidden cost of robotic milking.”

Biehl calculates that on his 125-cow dairy he was spending $5,700 a month on pellets alone to include them in his partial mixed ration. He believes his farm paid out $600,000 over the last decade by having the increased feeding bills associated with pellets. Calculating that decade-worth of pellet cost was a “real punch in the gut,” Biehl says.

“Innovation comes out of pain and challenges,” Biehl reflects. “I remember when my dad asked this question after those feed bills started coming in. He said, ‘Why can’t we feed all this high-moisture corn that we have stored? Why can’t we feed that in the robot?’”

That question led to the product that recently won the company a Nexus Innovation Award – a day hopper, auger and feed delivery system that is capable of serving high-moisture corn into feed bowls inside a milking robot. Biehl says the product can work with any brand of milking robot.

“Penn State University has done some trials and found the palatability and eating speed of high-moisture corn to be as good or in some cases actually faster than a conventional pellet,” Biehl says. “The moisture, the palatability of high-moisture corn allows the cow to consume it at a fast rate, and that’s what we need when we’re talking about trying to milk cows in six-and-a-half to seven-minute milking times.”

Biehl says the system’s design is flexible. More than a dozen have been installed so far, and only two of the systems are identically designed, Biehl says.

“We’re open to looking at anyone’s barn design so we can custom design the system – where the hopper might go, how the augers would be set up – and arrange things so the farm can be as efficient as possible,” Biehl says.

Early adopters report that the product has had a return on investment of no more than one year.

“That’s pretty incredible, really,” Biehl says. “It’s very exciting to be a part of a product that can add that much value to a dairy farm. What the high-moisture corn feeder has done is taken our dairy farm back to our roots and back to the profitability that we were used to seeing milking cows.”

Infrared manure drying, sanitizing system

BluTEQ’s system consists of augers that move separated manure solids under infrared lamps through a 30- or 50-foot run. The manure solids spend about 14 minutes under the infrared bulbs, which heat up to 1,000 degrees, killing pathogens in the manure in the first five minutes and drying the solids. Photo courtesy of BluTEQ.

BluTEQ’s system consists of augers that move separated manure solids under infrared lamps through a 30- or 50-foot run. The manure solids spend about 14 minutes under the infrared bulbs, which heat up to 1,000 degrees, killing pathogens in the manure in the first five minutes and drying the solids. Photo courtesy of BluTEQ.

BluTEQ Infrared Drying Solutions has harnessed the power of infrared lights to penetrate dairy manure and eradicate pathogens while also drying down the manure to use it as stall bedding.

“The infrared rays go into the sack of the bacteria. They heat up the water in the bacteria and they explode it,” says Chris Moarn, president of BluTEQ. “That’s how we kill bacteria.”

The infrared technology comes to the dairy industry from the municipal wastewater treatment industry. In that application, it is used to sterilize biosolids.

“When you use an infrared auger system like this, you’re going to get clean manure, a reduction in odor, total pathogen kill and hopefully an improvement in the number of mastitis cases and a lower SCC,” Moarn says.

The technology consists of augers that move separated manure solids under infrared lamps through a 30- or 50-foot run. The manure solids spend about 14 minutes under infrared bulbs, which heat up to 1,000 degrees, killing pathogens in the manure in the first five minutes and drying the solids to at least 44% dry.

“When we’re hitting it with those temperatures for 14 minutes, we’re not just killing pathogens; we’re taking a lot of water out of the product,” Moarn says. “And that’s how we get the product dry.”

The product comes out of the system at about 165 degrees. At an energy cost of 7 cents per kilowatt, the company says manure can be treated at about $5 per processed ton. The technology has been installed on two farms – one in Minnesota and one in Wisconsin.

While the system is a natural fit for dairies bedding with manure solids, Moarn says he’s had unexpected interest from sand-bedded dairies frustrated by the equipment and maintenance costs associated with handling sand.

“Eighty percent of the people [who] have come to our booth to discuss their situation have been sand people,” Moarn says. “The beautiful thing about our system is: You’re using your own manure. You’re paying next to nothing for that product. And it’s a dry, soft product. Cows seem to respond to it very well.”

Cloud-based, machine-learning digital dairy assistant

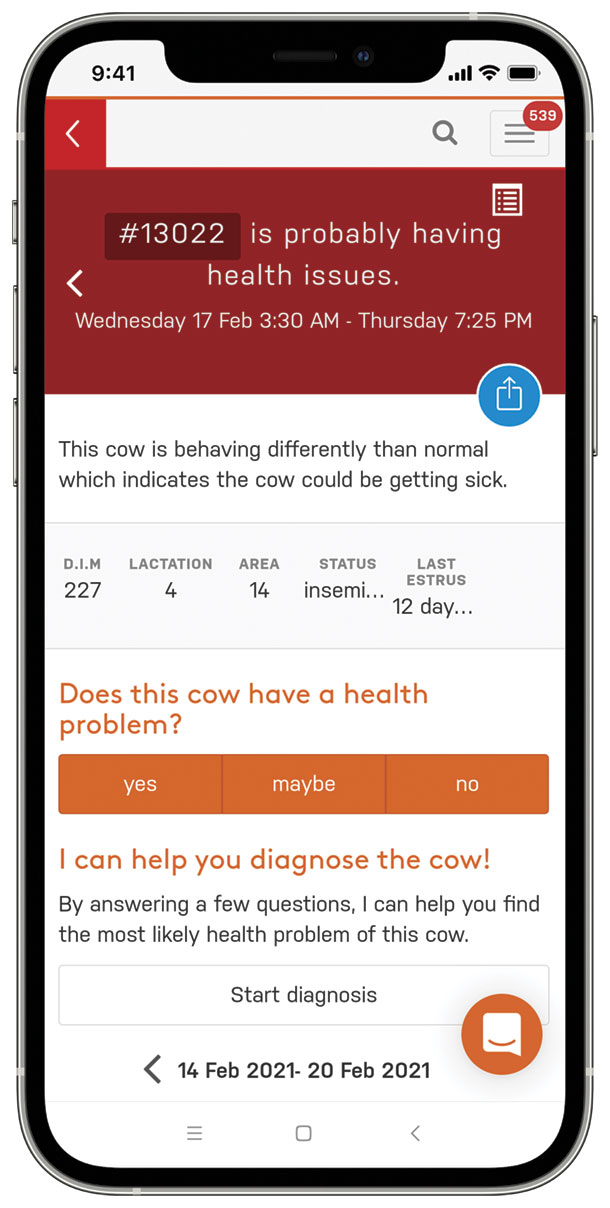

Connecterra analyzes data from its neck tag sensors in the cloud and delivers “easy to understand” farmer insights. The company’s machine-learning technology also considers human feedback, integrates with multiple farm management systems (FMS) and third-party data such as weather, genomics and feed software, to make ongoing data observations and suggestions even more accurate. Image courtesy of Connecterra.

Connecterra analyzes data from its neck tag sensors in the cloud and delivers “easy to understand” farmer insights. The company’s machine-learning technology also considers human feedback, integrates with multiple farm management systems (FMS) and third-party data such as weather, genomics and feed software, to make ongoing data observations and suggestions even more accurate. Image courtesy of Connecterra.

Connecterra has created Ida, the first artificial intelligence dairy assistant that analyzes herd information and generates plain-language, actionable insights in up to 11 different languages based on data collected from the farm.

“As humans, we’re not built to handle large amounts of data at a constant rate. In fact, the more data you give me, the less sense I can make out of it,” says Yasir Khokar, co-founder and CEO of Connecterra. “We don’t need more data. What we need out of the dairy data volume we have is more insights.”

Connecterra is building the shortcuts and intuition that the human brain is capable of creating for decision-making into machine-learning software and applying it for use with dairy cows.

“We call Ida a farmer’s assistant. It is a computer program, but it is also an artificial intelligence,” Khokar says. “It learns from you. And it helps you run a more efficient dairy farm, just like any high-quality, highly trained assistant would.”

How it works is: The data collected on the company’s neck tag sensors is sent to the cloud to digest and analyze a dairy’s data in order to deliver “easy to understand” insights.

“There is no data provided by Ida. Ida simply figures out what is going on and provides you, your farm, your staff the right information when you need it,” Khokar says.

It’s a lot more useful than other activity tags on the market, Khokar asserts. With those options, they just collect data and then leave it to you to read graphs or figure out what the data means.

“The great thing about Ida is that it learns from you,” Khokar explains. “For example, Ida can detect from data that a cow has a possible health problem. So it asks you a question. It says, ‘Does this cow have a health problem? Then you can go ahead and take a look at that particular cow and do a visual observation. Then you give it feedback about what the issue is.”

This is where Ida’s machine-learning is different. The human follow-ups make her next observations and suggestions even more accurate, Khokar says.

“The more feedback you’re giving Ida, the more it’s learning,” he explains. “Over time, it learns about your herd, your operation, your environment, and it gets smarter. With time, it’s actually going to tell you what that problem is with that cow.”

Each insight is available in real time on an easy-to-use smartphone, tablet or desktop app. Early adopters have seen heat detection improvements of up to 20% to 30% and pregnancy percentage rate increases of up to 15 points. Ida can detect health issues one to two days before they become apparent to humans, leading to a reduction of up to 60% of antibiotic usage. Labor costs on early adopting dairies have been reduced by as much as 20% per month.

Ida can also keep track of management changes on a farm. Say, for example, a farm switches to a different type of bedding. A farmer can tell Ida what day the change occurred, and its machine learning can analyze if it was “a good or bad change.”

“It’s going to tell you what happened to your milk yield, what happened to your herd’s behavior and, ultimately, if you get the right result.” Khokar says. “Now you’ve got data-driven evidence to figure out if the practices you’ve been doing, or the practices you’re being advised to do, are the right ones for your operation.”