The innovation – named the Teatwand Parallel – will be installed on the first U.S. dairy in northern California at the beginning of the year and should be available commercially by the middle of 2022. It’s been named one of the World Ag Exp’s Top 10 new products.

The technology has been operating on one of New Zealand’s few parallel parlors for two years. Export of the technology to the U.S., where there are many parallel parlor systems, has been slowed by the COVID-19 pandemic.

“Every time we go to a show in the U.S., we have dairy producers say, ‘Great, you’ve got automated teat spraying for rotaries. When are you going to do something for parallel parlors?’” explains Gary Arnott, CEO of Onfarm Solutions, which developed the product. The company has automated teat-spraying solutions for rotaries that include teat-spraying wands and step-over solutions.

“This new system is designed squarely for dairies in America,” Arnott says.

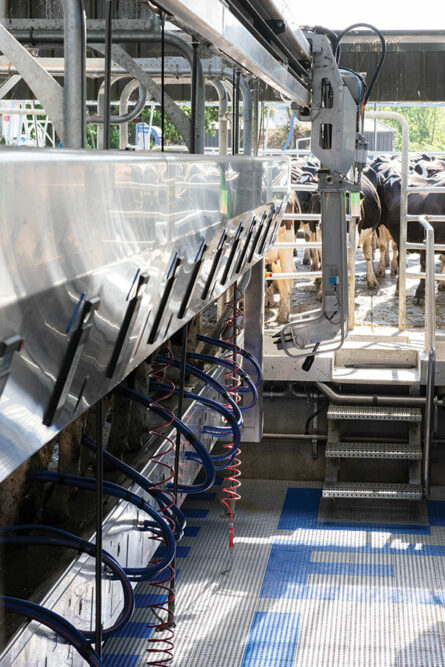

The systems uses multiple spray arms that are suspended from a gantry and travel up and down a parallel parlor for pre-spray and post-spray activity. Each spray arm can service up to 15 stalls.

For example, in a double-30 parlor, the system would utilize a total of four spray arms – two per side – all working independently from each other to prep cows.

Each spray arm monitors for cows in their 15-stall service area to load for milking or that finish milking. The spray arm will move to a cow as soon as her milking claw is removed regardless of her position in the parlor lineup. The spray arm then stops in the correct position, and a spring-mounted spray wand extends under the cow’s udder. There are two independently controlled nozzles on the wand. One is angled forward and sprays the teats as it extends. The second nozzle is angled back and sprays as the wand retracts, covering all sides of each cow teat. Different spray solutions can be used for pre- and post-spraying. The system has a flush system to clean out one prep solution before switching to another.

The moving arms have flashing lights to alert workers when they are active and about to move. If a human does get too close to the system in operation and bumps one of its crash bars, the system stops immediately and must be reset.

“Fully automated teat spraying in parallel parlors – that’s what we’ve created, and it’s a world-first,” Arnott claims.

Onfarm Solutions has been innovating with automated teat spraying since 2008 and has sold its products in the U.S. since 2015.

“Teat spraying is the most important mastitis management practice a dairy can have in its toolbox, and it must be done well,” Arnott says. “Automating this task buys peace of mind, knowing the job is done properly for every cow in the herd.”

Teatwand Parallel

Onfarm Solutions

Exhibit space: Farm Credit Dairy Center 6220, 6221, 6222 ![]()

Courtesy photo.

-

Walt Cooley

- Managing Editor

- Progressive Dairy

- Email Walt Cooley