The current economic context implies a high level of market uncertainty. Consequently, caution should be exercised when it comes to major expansion or investment projects. Yet, things will eventually settle, and preparing now to be ready to implement future projects could be time well spent.

When considering major changes in production technology such as the adoption of automated milking systems, identifying and quantifying the main costs and benefits is a crucial part of the planning process. In 2019, a survey of 200 automated milking system adopters was jointly conducted by the extensions of Wisconsin, Minnesota and Pennsylvania. Estimates of three major economic impacts of automated milking systems adoption were obtained: change in milk production, change in labor, and repair and maintenance costs.

Impact on milk production and quality

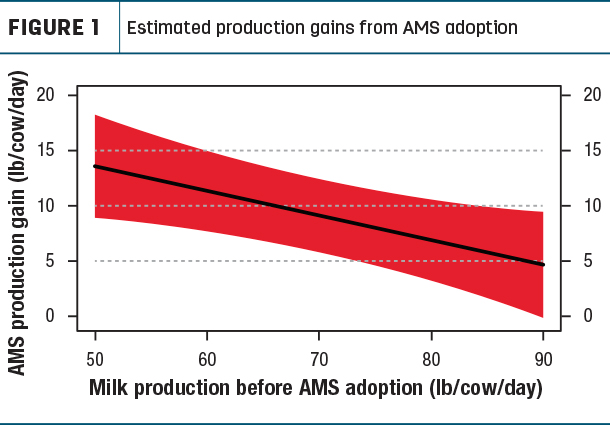

Most farms will bring in various changes to their operation as they adopt automated milking systems, including potential changes to housing, bedding and feeding, all of which can help boost production. Controlling for these changes, we find that the biggest factor affecting production gains remains the initial productivity of the herd. Figure 1 makes it clear that production gains are much more modest for herds that were already highly productive.

Someone adopting automated milking systems with a 50-pound-per-cow-per-day herd can expect production to rise by 13.6 pounds per cow per day. For someone starting with a 90-pound-per-cow-per-day herd, the expected gains from adopting automated milking systems drop to 4.7 pounds per cow per day.

Respondents reported a steep learning curve for automated milking system management. Most producers indicated that they needed about six to 12 months to operate automated milking systems at a satisfactory level. The gains shown in Figure 1 represent the expected long-term production gains realized after the first year of installation and are based on the assumptions that the herd was originally milked twice a day, that the automated milking system technology is installed in a new building (not retrofitted) and that there was no change in bedding.

The impact of automated milking systems on milk quality was mixed. In general, those that started with higher milk quality saw a deterioration after adopting automated milking systems (e.g., somatic cell counts moved from 100,000 to 150,000 cells per milliliter). But those with lower initial milk quality saw improvements. No significant impact of automated milking systems adoption on milk components was found. When analyzing the impact of automated milking system adoption on energy-corrected milk production, the results were similar to those reported above.

Producers’ comments

- “It is very important to have a nutritionist who is familiar with robots.”

- “The first two weeks we were in the robots were by far the hardest part.”

- “Still learning every day. SCC did finally come down (150k) after nearly three years.”

Labor savings from automated milking system adoption

Most dairy producers expect some labor savings from automated milking system adoption, and for some it might be the main motivation. But exactly how much labor savings can realistically be expected, and what are the key factors determining those savings?

Our sample of automated milking system adopters shows an average labor savings above 0.06 hour per cow per day, or 0.1 hour per hundredweight (cwt).

Labor efficiency was calculated as the total number of hours of labor per day (employee and owner) for the milking herd, including milking, feeding, bedding, breeding, treating, cleaning, etc., divided by either the average herd size to get hours per cow, or by the average herd milk production to get hours per cwt.

Among our respondents, labor efficiency ranged from 0.2 hour per cow or 0.28 hour per cwt for the least efficient to 0.07 hour per cow or 0.1 hour per cwt for the most efficient after automated milking system adoption. At a wage rate of $15 per hour, that would amount to a cost savings of $1.50 per cwt.

It might also be useful to think of potential labor savings in percentage terms. Our respondents, on average, reduced the amount of time required per cow by about 38%, and the time required by hundredweight by about 43%, as automated milking system adoption usually increases production per cow.

There were large variations in the labor savings reported. At the lower end, around 8% of our respondents reported no labor savings at all. Many of those respondents cited maintenance and repair issues as a primary concern and a source of unexpected/additional labor needed to run the automated milking system. At the other end of the spectrum, 25% of our respondents reported labor savings above 0.1 hour per cow or 0.16 hour per cwt ($2.40 per cwt assuming a wage of $15 per hour).

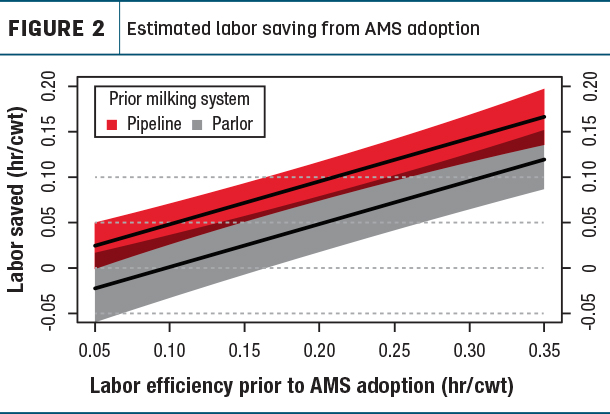

A major determinant of labor savings is the original milking system that the automated milking system is replacing. Those that had a parlor saved 0.08 hour per cwt on average, while those with a pipeline saved 0.16 hour per cwt on average.

The other main determinant of expected labor savings is a farm’s labor efficiency prior to automated milking system adoption. Figure 2 shows the positive relationship between a farm’s initial efficiency level and the estimated labor savings, depending on whether it transfers from a parlor system or a pipeline system.

Producers’ comments

- “Anyone considering robotics should understand that there is still plenty of daily work involved in milking; robots just give you more flexibility with your time.”

- “Still need experienced labor to keep robots running.”

- “Automated milking system is not stress-free. Physically, it is easier. Mentally, it can be stressful.”

Repair and maintenance costs of automated milking system units

Robotic milking implies large capital investment, which brings ownership costs including depreciation, interest and repairs. The lifespan of automated milking system units and the repairs are often subject to discussion. Our sample included producers that adopted automated milking systems as far back as 2008 and as recently as 2019. We asked each of them to report the average maintenance and repair costs over the last three years. We also asked them about the expected lifespan of their automated milking system units and some details about recent major repairs.

The average expected lifespan of automated milking systems was just above 15 years. That number did not change between those with retrofitted and new housing. Neither did it change much between those that recently installed automated milking systems and those that have been operating automated milking systems for more than five years. Overall, about a quarter of the respondents expected a total lifespan of 13 years or less, while another quarter of the respondents expected a total lifespan of 18 years or more.

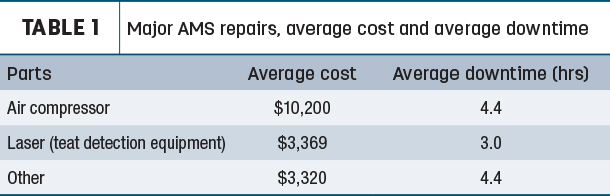

In the early years, repairs and maintenance costs totaled around $5,000 per robot per year on average. Those average costs increase above $10,000 as the automated milking system unit gets older. This is mainly due to higher repair costs, since maintenance costs remained somewhat constant over the automated milking system lifespan. Table 1 provides a short list of most frequent automated milking system repairs and the average cost and downtime associated with them.

A key element believed to help minimize the risk of failed automated milking system adoption is the availability and quality of customer service from automated milking system dealers. The survey showed that most producers are satisfied with the customer service they received. Maybe more importantly, 45% have indicated improvements, while 19% indicated deterioration of service since they adopted automated milking system technology.

Producers’ comments

- “If you don’t have a quality service or company, it will not work.”

- “Service is critical, and parts are expensive. You want a reliable machine and a company that will teach you how to fix and maintain it.”

In conclusion, these numbers should help you develop your own investment plan, with the help of a business consultant if needed. In the process, it is important to identify the risk factors you will be facing and establish under what conditions automated milking systems would make sense for your operation. With a good plan in hand, if those conditions arise in the coming years you’ll be well prepared to take action and get all your people on board, including partners and lenders.