Dairy production in the U.S. is coming under closer scrutiny because of concerns about the environmental quality impacts from all phases of the production system. There are multiple phases of a dairy production system that range from forage or grain production, facilities for feeding, housing and milking cows, manure management and potentially pastures for animal grazing.

Environmental concerns range from surface or groundwater quality to air quality.

Within each of these different phases there are a variety of different compounds that can impact environmental quality. One of the challenges producers are increasingly beginning to wrestle with is how to quantify the air quality impacts from various segments of the dairy production system.

Accurately measuring air quality impacts of agricultural systems is difficult because, in an agricultural environment, there are a large number of different compounds in the air. These compounds can range from particulates (dust), ammonia, greenhouse gases (methane or nitrous oxide) and volatile organic compounds (odors), each of these requiring different methods to measure their concentration in the air.

Traditional methods for measuring these compounds involve samplers placed in specific, stationary locations within the facility; by combining the results from several of these samplers, it is possible to estimate the total amount of any gas or dust particulate emitted by the facility.

One of the difficulties with this approach is that single or even multiple sampler approaches often do not adequately represent the overall facility or even a single field. Furthermore, the sampler may not be placed in the right location around a facility to appropriately represent the average concentrations.

This is a major problem we have been addressing through a partnership between the USDA-ARS National Laboratory for Agriculture and the Environment in Ames, Iowa, and the Energy Dynamics Laboratory at Utah State University in Logan, Utah.

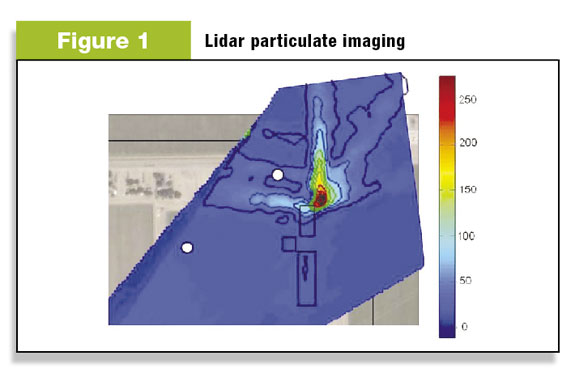

There are alternative approaches to single samplers and we have been working over the past five years to develop and evaluate a method that uses lidar (light detection and ranging) equipment coupled with a series of particulate samplers to measure dust emissions. The initial focus has been on the measurement of particulates in the air around dairies because detection of particulates is somewhat easier than detecting airborne gases.

Our lidar system allows us to visualize how a plume of particulates might move around a facility. Lidar is the laser equivalent of radar; one simple way to explain how a lidar system works is to imagine a large laser pointer that shines light out across a facility attached to a very sensitive light detector, which is used to measure the amount of light reflected back to the laser pointer by any airborne dust.

The more particulates in the air, the more light is reflected back to the detector.

This is much like driving a car on a foggy night; the light from headlights is reflected back to the car and the heavier the fog, the more light is reflected back. Dust particles invisible to the naked eye are easily seen using lidar. By using different colors of laser light, this system can not only measure the amount of airborne particles, but it can measure the size of the particles, too.

By scanning the laser beam around the facility, it can provide a snapshot view of the overall plume of particulates emitted from a facility. This approach is much more complex than it may appear, because it represents a combination of both physics and mathematics applied to real-world agricultural problems in order to provide new insights in how air and particulates from agricultural operations move around buildings.

We have applied this technology to different tillage operations to be able to understand how particulates of different sizes are released during tillage and how the plume of particles moves across a field. The advantage of this technique is that we can view the complete tillage operation as the tractor moves across the field. This allows us to obtain a field-scale estimate of the particulates released during an operation.

We are now in the process of comparing different tillage operations and have shown there is a difference between tillage systems.

Another application has been to dairy operations in which we have examined the particulate plumes being emitted from a facility throughout the day. We can relate these plumes to animal activity and management practices. Using this type of technique, we can begin to compare different management practices for their effectiveness on dust control to help producers determine the best management practices for their facility.

The next extension of our work is to incorporate different gas samplers, which will allow us to measure a variety of gases and relate these to air movement patterns and management practices. This will allow us to achieve our goal of improving air quality around agricultural operations by being able to understand the processes affecting air quality, but also provide potential solutions for producers to adopt in their operations. PD

The Energy Dynamics Laboratory is operated by Utah State University in Logan, Utah. Wojcik is an environmental scientist at the laboratory. Jerry Hatfield is the director of the USDA-ARS National Laboratory for Agriculture and the Environment in Ames, Iowa. Randal Martin is a professor of environmental engineering at Utah State University.

References omitted due to space but are available upon request to editor@progressivedairy.com .

PHOTO: Accurately measuring air quality impacts of agricultural systems is difficult because, in an agricultural environment, there are a large number of different compounds in the air. Photo courtesy Energy Dynamics Laboratory.

-

Michael Wojcik

- Branch Chief of Environmental Sensing

- Energy Dynamics Laboratory

- Email Michael Wojcik